Case Studies

Filter

By Industry

By Product

By Application

A leading French machine maker for the papermill industry needed an efficient solution for their new high-speed rewinding machine line.

The company needed a solution to improve the separation of waste from raw materials, and improve quality of externally sourced recycled PET flakes.

A Polish plastics recycling plant overcame the challenge of cleaning regrind material with Kongskilde’s AirWash system.

A manufacturer of food packaging films was looking to replace outdated equipment to improve trim handling efficiency from their extruder lines.

The company requested a system that would cut away the logistics of having a forklift operator transport pallets back and forth to save time and increase safety.

A polycarbonate film & sheet producer in the Netherlands needed a pneumatic trim removal system installed in an air-controlled clean room.

The Challenge A factory located in Poland is a well-known producer of different kinds of books for the domestic and international marketsThe client has five production lines. Trimmings are generated on machines of the three-side trimmer type; a “woolly” paper dust is generated by the cutter machineHowever, the old system […]

A tea producer in Poland needed a solution to extract trimmings from production to reduce downtime and improve efficiency.

PET bottle producer required a solution for reducing and collecting dust directly from their production.

A yogurt producer in France wanted to eliminate plastic waste from production lines and reduce manual labour requirements, and separate materials.

An automotive manufacturer in the USA needed a solution to remove dust from the work environment and increase the use of regrind material.

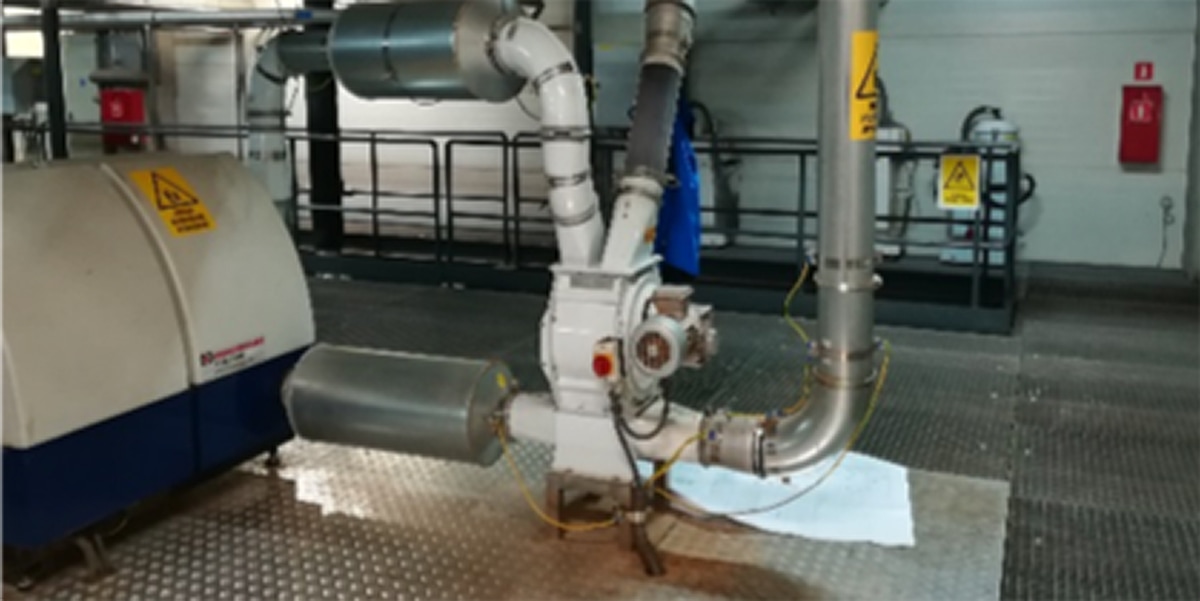

A Dutch blow moulding producer needed a solution for reducing dust, angel hair, and peroxide fumes on their production sites.

Belgian manufacturer of high-performance extrusion coated and multilayer products needed a replacement for their old cutter system.

Manufacturer of personal care products located in Poland needed a friction-free conveying solution for soap granulates.

Producer of children’s car seats in France needed a solution for reducing the need for manual labor and mechanical systems.

A pneumatic solution from Kongskilde for the conveying of regrind material minimizes dust and improves productivity.

A Polish producer of apple juice needed a solution to remove dried apple pomace from production quickly and efficiently.

Injection moulding manufacturer in the Netherlands needed a higher capacity solution for transporting plastic granulates to silos.

An international company known for their wall coverings needed a solution to gently transport trim and improve fire safety.

A world-famous liquor producer located in France needed a solution to eliminate manual transport processes in their production.

A stamping machine market leader located in Germany needed a solution to eliminate manual labour for handling edge trims.

Worldwide confectionary producer needed a solution that would reduce manual labour, increase productivity, and improve the work environment.

A Danish waste municipality needed a solution that would improve the work environment and simplify the conveying process.

US-based plastic bag producer needed a flexible conveying solution for fast and reliable transport of PP and PE pellets from rail cars.

Label converter located in the UK needed a new guillotine and wanted to free up space in the production area to reduce downtime.

Producer of non-combustible mineral boards located in Slovenia needed a solution to reduce dust and noise in their production.