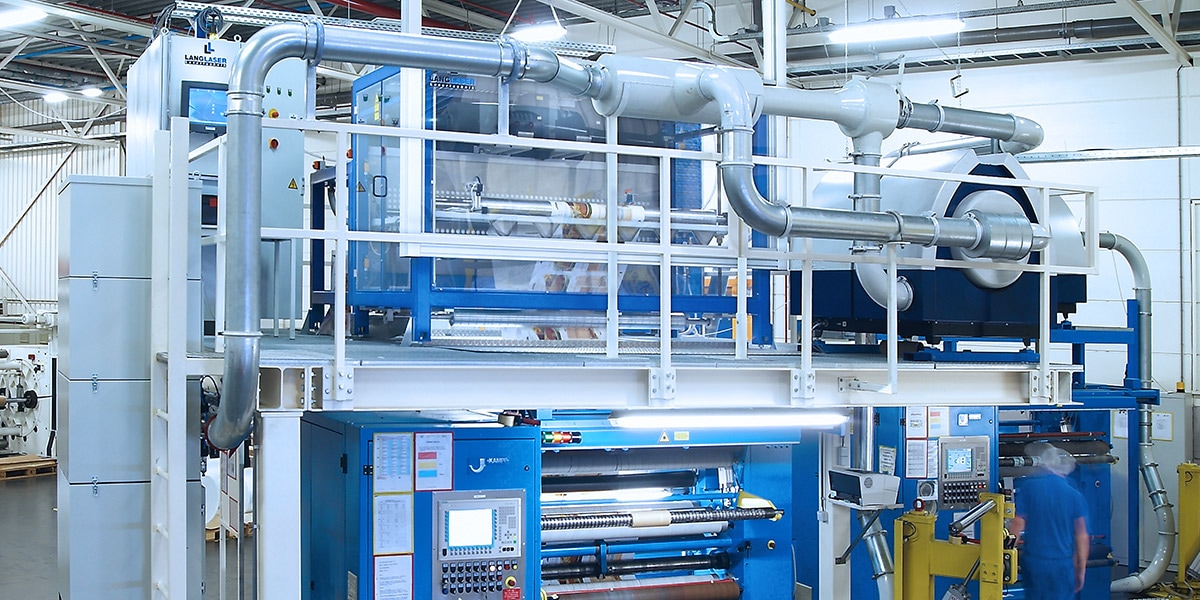

Trim Handling Systems

Optimize production capacity with efficient trim handling systems for the modern processing of paper, plastic, foil, and cardboard. For further information contact us or select your solution below.

Finding the right trim handling system

We have various innovative solutions available to efficiently and easily convey trim. At Kongskilde Industries we offer cost effective ways for you to handle trim with low maintenance and labour costs, regenerative and exceptionally quiet design, and modern hardware.

What is a trim handling system?

Trim handling systems extract trims from several materials including, but not limited to, paper, plastics, foil, and packaging material. The trim handling process may include, for example, the pneumatic conveying of paper edge trims. We have various innovative solutions available at Kongskilde Industries to suit your needs: providing the means to efficiently collect diverse trim materials and easily transport them from a production line to a collection area.

There has been a definite trend toward selecting vacuum trim conveying systems in industrial functions, due to greater winder speeds, stricter noise control, energy conservation, and the ability to keep different types of waste separate from each other for reselling purposes. Production lines can use suction to remove edge trim waste material, downsizing it during conveying.

Why do materials need to be trimmed to begin with?

Taking paper as an example, to avoid issues such as press jams or other mechanical problems, one must trim the paper prior to printing to ensure that all edges are perfectly straight and aligned. In operations such as binding and finishing, trimming occurs to reduce sheets to the desired trim size.

In some cases, the manufacturing process can return trim, thereby reducing the waste leaving the paper mill. When producing coated, colored, or otherwise special papers, the trim may partially or entirely discard.

What components make up a trim handling system?

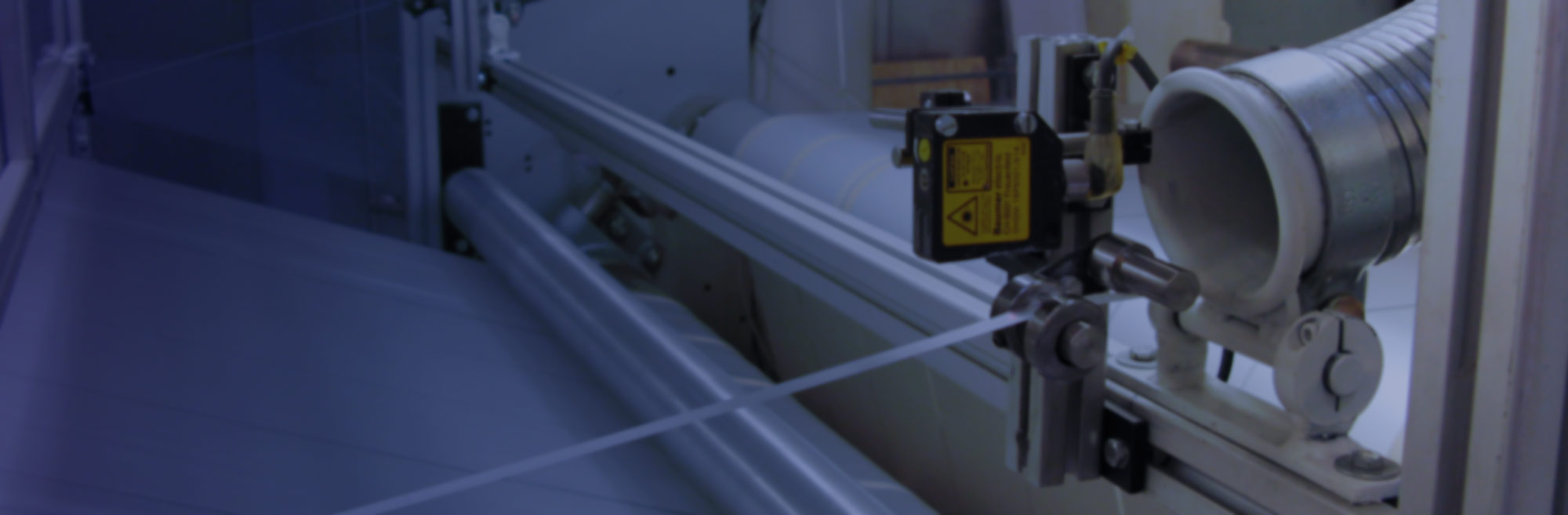

Trim handling systems can use various sizes of blower and Venturi. Blowers develop air pressures that proceed through the Venturi to create vacuums at the source, pulling trim into the system.

Further components can integrate into trim removal systems; inline cutters can guide materials to flow through, collecting them in a Kongskilde multi-separator RVS unit and releasing them pressureless from the bottom. Adjustments to system layouts and sizes can accommodate evacuating trim from multiple production machines to a single delivery destination and fitting spacing demands or limitations of particular premises. Alternatively, material can be directed to various destinations.

What are the benefits of a trim handling system?

An effective trim handling system can reduce the volume of waste at a discharge point and convey cut trim over longer distances. Vacuum trim removal systems produce low levels of noise, compared to traditional options, and they eliminate dust problems along the trim duct route, hence making them preferable for work environments.

Every solution from Kongskilde Industries is a tried and tested way of conveying trim with a multitude of applications. Installing a long-term trim handling system does not necessarily have to mean it cannot also be easily modified to adapt to changes in the production flow.

Questions?

Get in touch with our world-class customer support and technical specialists.