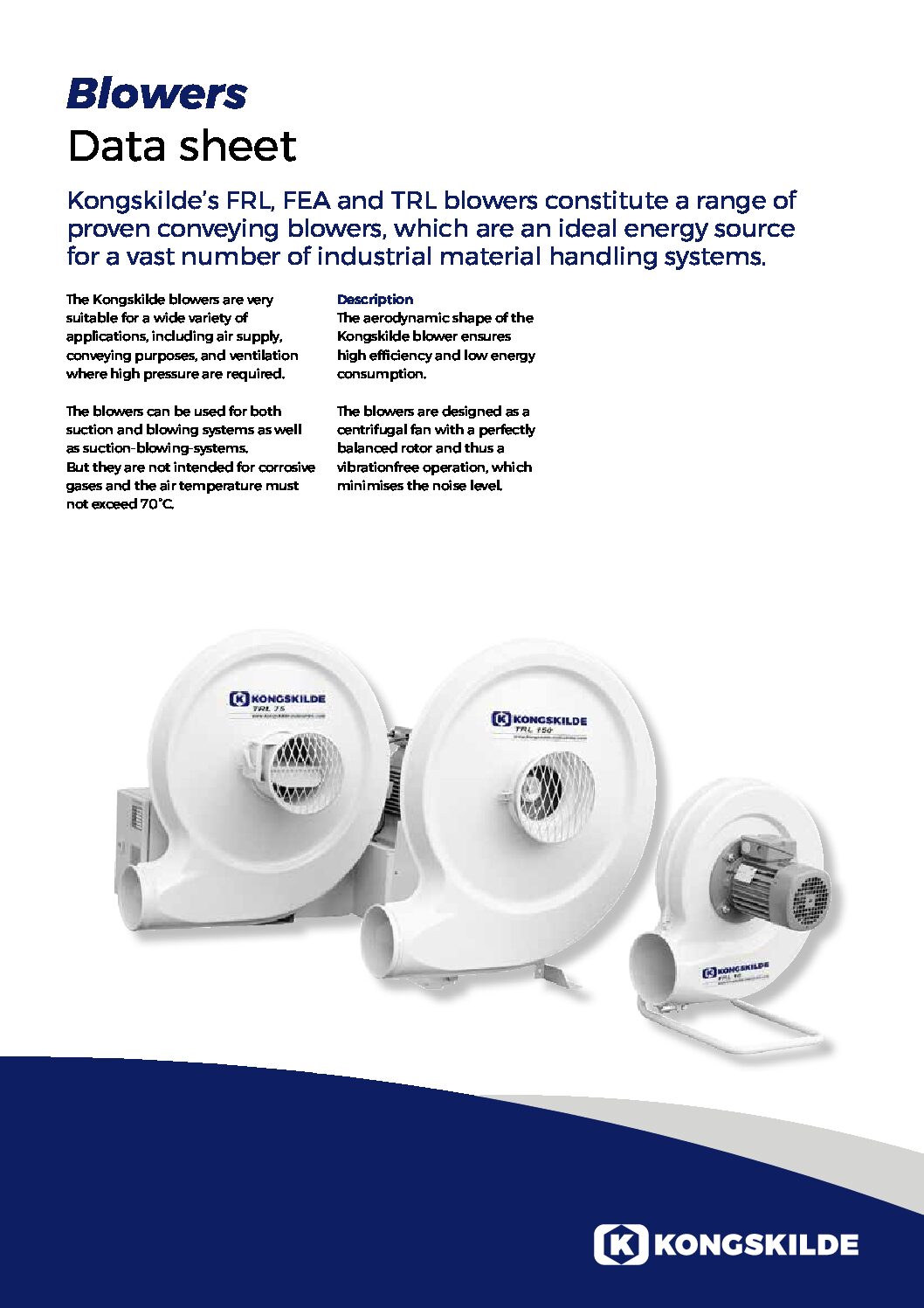

Conveying Blowers

FRL / FEA Blowers

Conveying blower designed for ventilation tasks

The Kongskilde FRL blower models are suitable for exhaust purposes of light material as e.g. plastic flakes, light dust and shavings.

The Kongskilde FEA blower model is very suitable for a wide variety of applications, including air supply, conveying purposes, and ventilation where high pressure is required.

The FRL/FEA blower is available in 50 and 60 Hz models.

Downloads

Compare Models

Downloads

Downloads

Download manuals, data sheets, and spare parts lists for the FRL and FEA blower. For wiring diagrams, please contact us.

Data Sheets and Manuals

Spare Parts

Compare Models

FRL/FEA Blower Model Comparison

Compare available FRL/FEA blower models. Visit the downloads section for more information on specific models.

| FRL 10 | FEA 10 | |

|---|---|---|

| Motor rpm | 2900 | 2900 |

| Amp. Consumption | 1.7 | 1.7 |

| Motor rating, kW (Hp) | 0.75 (1) | 0.75 (1) |