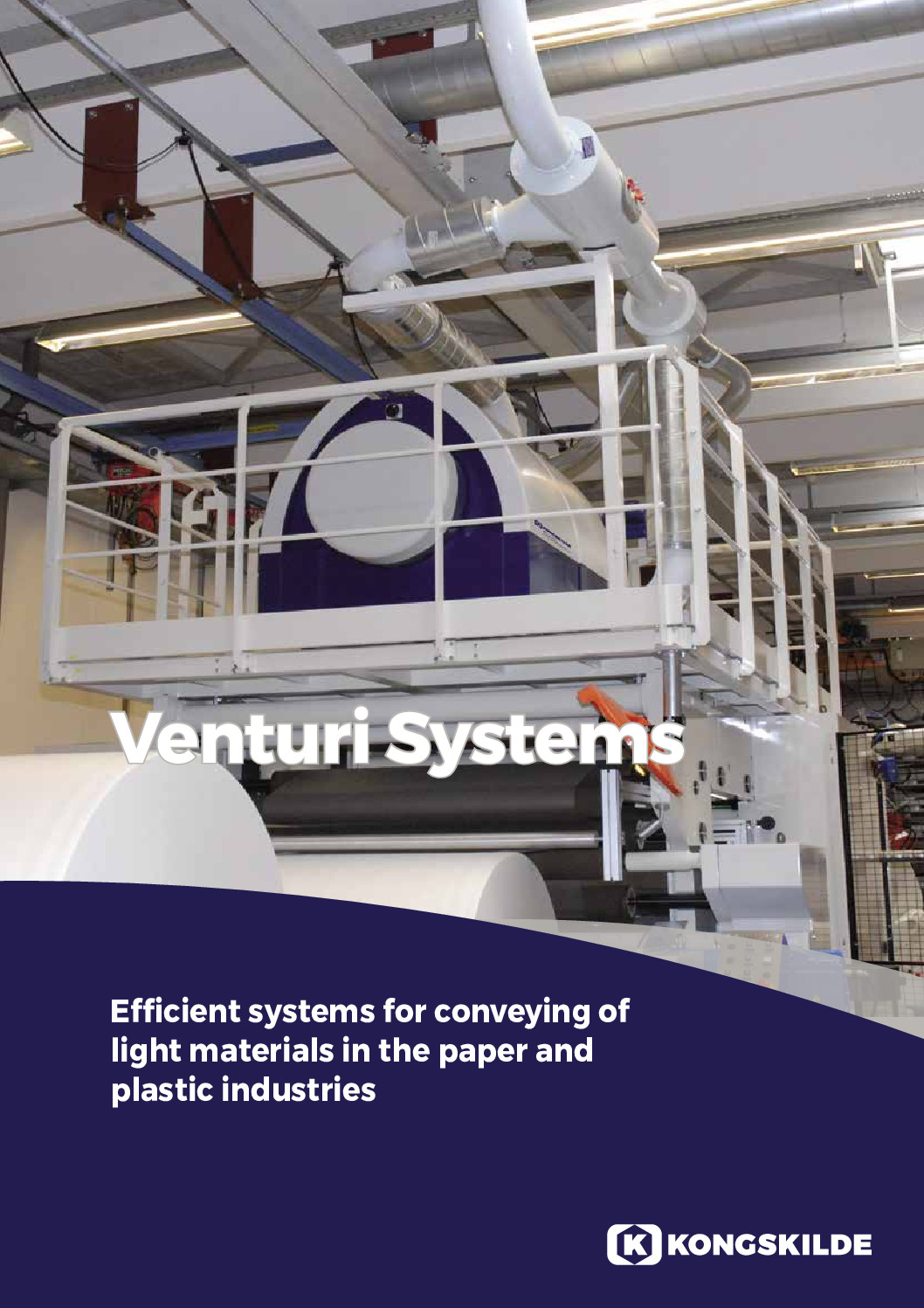

Kongskilde’s off-cuts handling solutions offer efficient trim extraction systems to meet the demands of high-speed production in many of today’s modern industries.

Pneumatic trim extraction systems have the unique ability to remove shredded materials and cut waste quickly while keeping production spaces clean and easily maintained.

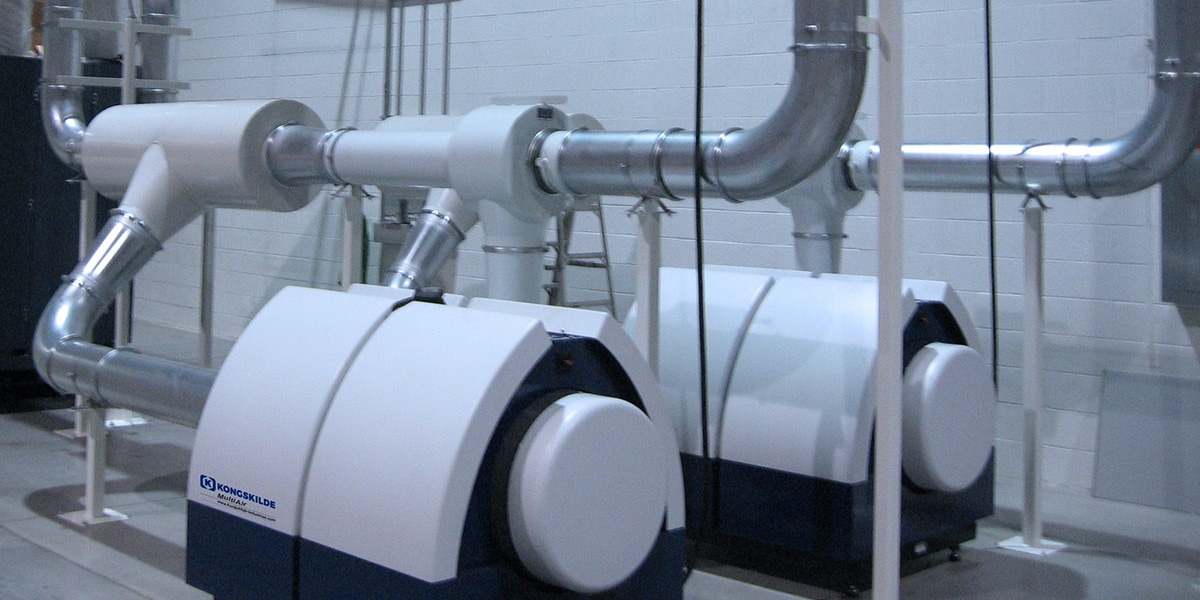

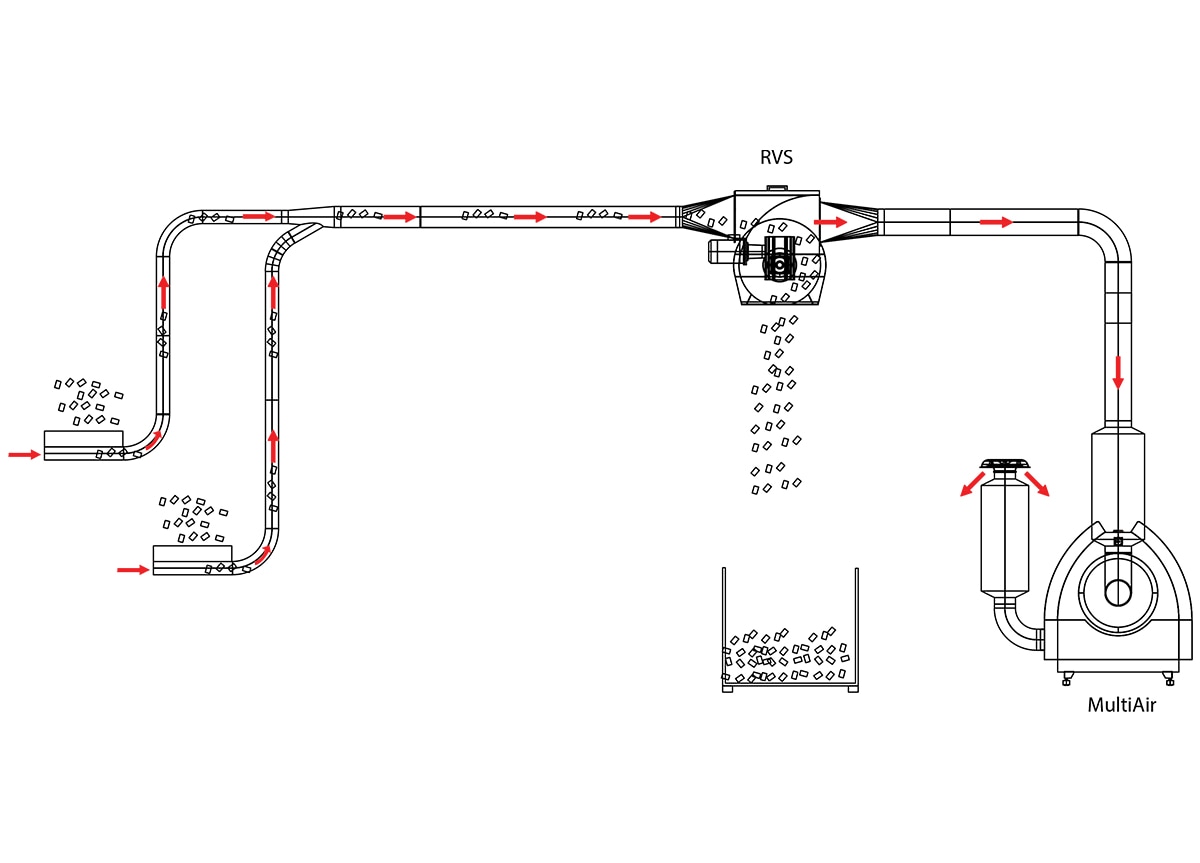

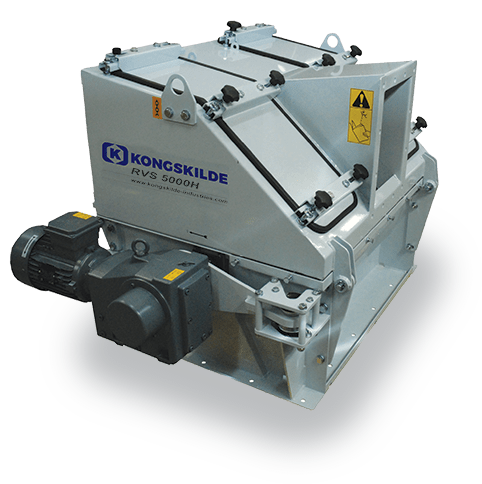

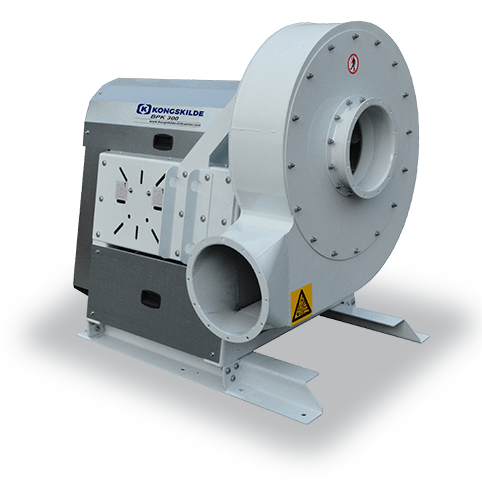

Our two principal solutions are the Kongskilde Inline Venturi (KIV) and the RVS (Rotary Valve Separator ) system. The KIV system utilizes a continuous pipe run with a vacuum on the pick-up side and pressure on the blowing side to push material to one or more discharge destinations. Whereas, the RVS system utilizes the vacuum side of the blower to create suction in the pipe system to pull off-cuts into the separator. It can be sized to evacuate trim over longer distances from several production machines to one delivery destination.

Video of Pneumatic Conveying of Off-Cuts

The automated extraction of the cardboard off-cuts enables a fully automated operation.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Trim Extraction System for Book Production Minimizes Downtime and Recovery of Warm Air – Poland

The Challenge A factory located in Poland is a well-known producer of different kinds of books for the domestic and international marketsThe client has five production lines. Trimmings are generated on machines of the three-side trimmer type; a “woolly” paper dust is generated by the cutter machineHowever, the old system […]