Applications

Boost the Performance of Your Agri-Business with Kongskilde Grain Solutions

Enhance your grain management productivity with high-performance conveying, cleaning, and storage solutions from Kongskilde. Renowned for their flexibility, reliability, and quality, our world-class grain solutions streamline project planning and execution, ensuring superior handling and storage of grain with unmatched expertise. Optimize your agricultural operations with our advanced, efficient grain systems tailored to meet specific industry needs.

Filter

By System

By Industry

By Product

Minimize the content of leaves and dust in the crop, and make storage safer using aspiration cleaning.

The most ideal solution is to have the weigher built into the conveying system for storage filling

In various plants, i.e. for seed cleaning, several fractions of grain and waste have to be conveyed separately away from the cleaning machine.

The two sizes of seeds are separated using screens with perforations adapted to the size of the seed kernels.

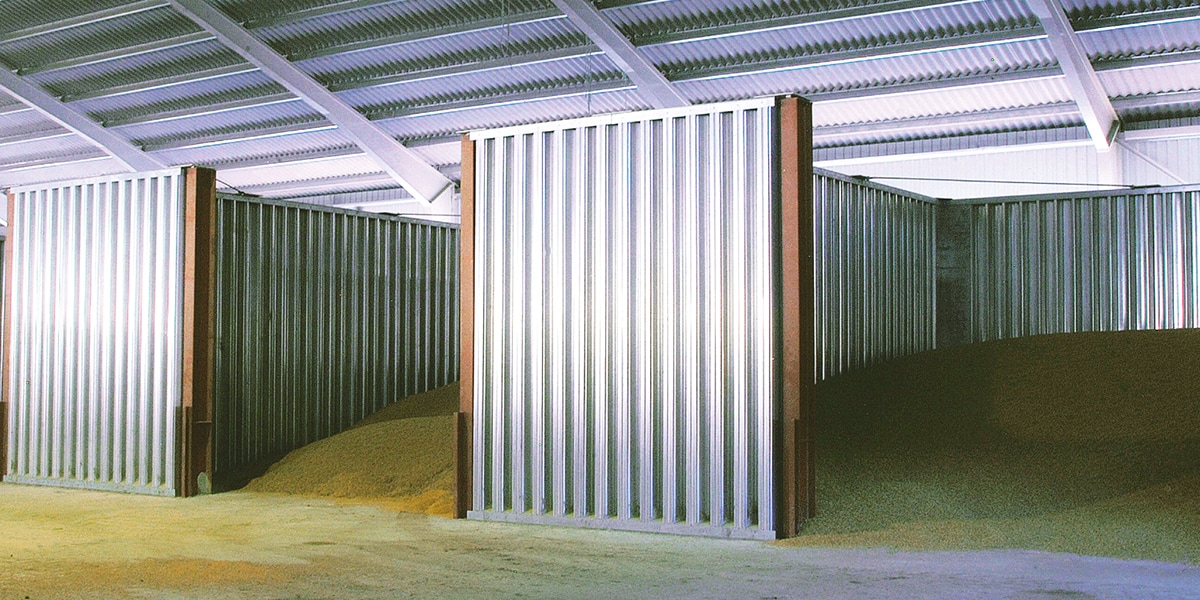

A pneumatic conveying system for filling of on-floor storage can easily be installed everywhere.

Bucket elevators are the gentlest conveying for vertical lifting when conveying seed grain.

Grain is used for various products where the specification of size of the single kernel is a demand criterion.

With this pneumatic conveying solution, you can load the grain directly off the field

The easy and efficient solution for conveying of grain from trucks to railcars is to use a suction blower.

Kongskilde offers solutions based on a conveyor placed at the bottom of a pit to convey the grain horizontally to the intake of a bucket elevator.

You can mechanically convey grain to and from a continuous flow drier

A high capacity mechanical system can effectively fill and empty bottom hopper silos.

A high capacity mechanical conveying system to transport grain to and from silos can be based on bucket elevators and chain conveyors.

Kongskilde offers pneumatic conveying systems for conveying of grain from the pit into wet holding bins, driers, or storage silos

With this pneumatic solution, more hopper silos can be emptied by the use of only one blower.

A conveying solution for filling of siloes can easily be based on pneumatics. It is only the pipes which need to go from ground level to the top filling point of the silo

A clean crop without impurities and dust is much easier to store safely.

To remove more heavy impurities in the grain, it is necessary to use a screen cleaning process, also for the pre cleaning.

Pneumatic vacuum systems are efficient solutions for evacuating grain from all corners of the storage.

A Kongskilde solution will help alleviate the problems with grain infected by fungicides or other unwanted remains sitting on the kernel surface.

Wooden silos are suitable for indoor drying and storage of grain and ideal for safe storage of in-bin drying of grain with less than 18% moisture content

Kongskilde’s ventilation solutions are especially developed to be used for ventilation of on-floor storage with grain.

Efficient conditioning of the grain in a silo storage is important to keep a high-quality crop.

The weighing system is based on a compartment containing a certain amount of grain