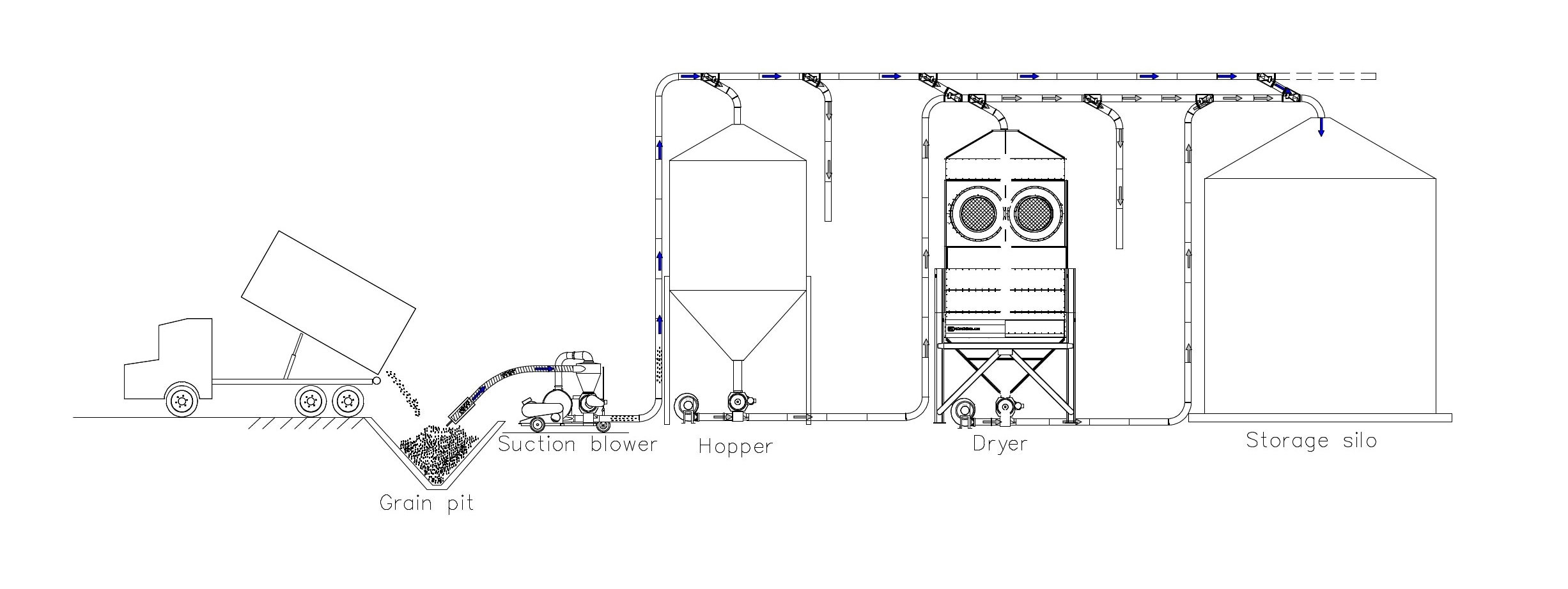

Pneumatically Conveying System for Grain Dryers

Kongskilde offers pneumatic conveying systems for conveying of grain from the pit into wet holding bins, driers, or storage silos

Conveying System for Grain Dryers

Kongskilde offers pneumatic conveying systems for conveying of grain from the pit into wet holding bins, driers, or storage silos; and from the wet holding bin into driers or storage silos; as well as conveying from drier into storage silos.

This is a full flexibility system allowing for continuous use of the flow drier, working independently of the grain conveying process from the intake pit to the wet holding bin. This allows for the drier to run continuously at maximum capacity. During wet harvest seasons, the drying capacity is often a bottleneck.

In case the system is based on a batch or recirculating drier, the system can be designed with fewer conveying systems. One or two blowers have to be in operation depending on the demand for drying efficiency.

Video of pneumatic grain conveying

The SUC-E by Kongskilde Industries are ideal for both indoor and outdoor pneumatic conveying jobs. The SUC-E models are provided with wheels and can easily be moved from one job to another.

Businesses We Serve

Whether your business deals in organic or conventional farming, Kongskilde has a solution designed to optimize your processes and production.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Related Products

Designed for maximum flexibility, reliability, and quality, Kongskilde’s portfolio of complementary products offers additional customization for our world-class pneumatic systems.