Mechanical Conveying

Kongskilde mechanical grain conveyors provide an efficient and reliable solution for moving large volumes of grain and granular materials within agricultural settings. These systems are designed for durability and can handle the rigorous demands of continuous operation, ensuring a constant flow of materials with minimal downtime.

Mechanical grain conveyors offer the flexibility to work in various configurations, including vertical, horizontal, and angled setups, making them ideal for complex facility layouts. These conveyors are built to maintain the integrity of the grain, preventing damage during transport and preserving quality from field to storage.

About Mechanical Grain Conveyors

Grain conveyors, including mechanical conveyor systems and grain belt conveyors, utilize a continuous belt or chain mechanism that moves bulk grains from one point to another. These systems are engineered to transport large quantities of grain efficiently, minimizing manual handling and enhancing productivity in agricultural operations.

Efficient Mechanical Grain Conveying Solutions

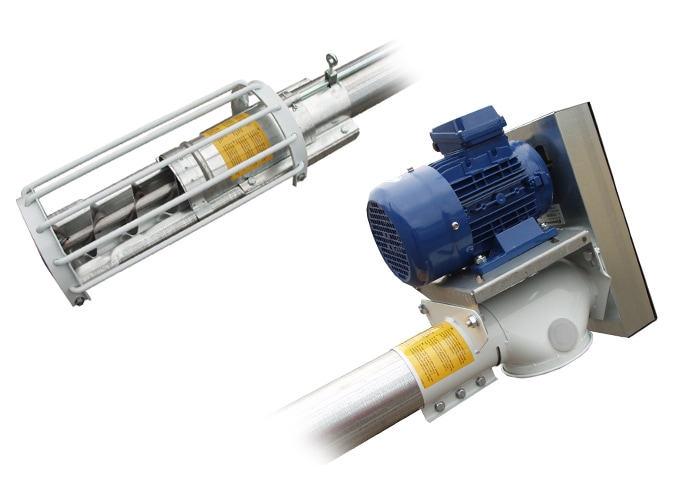

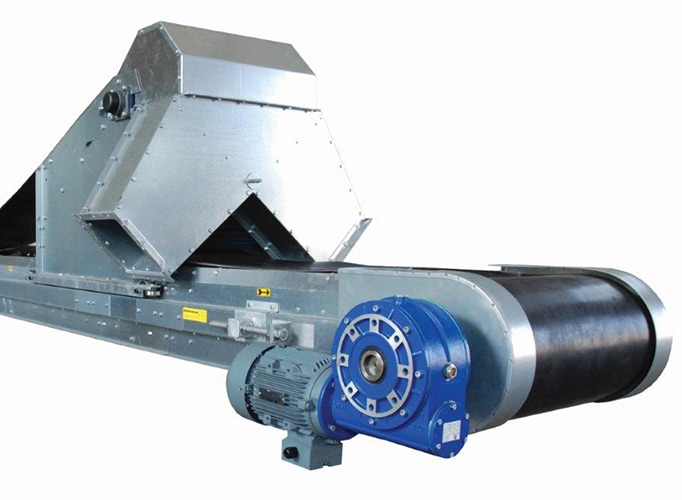

Mechanical grain conveyors, such as bucket elevators and belt conveyors, are ideal where a permanent high-capacity system is required.

Efficient and able to convey a wide range of grain, Kongskilde grain conveyors can easily be equipped with different accessories to meet the requirements of the specific installation. Kongskilde grain experts are happy to help choose the right type of grain conveyor depending on the type of crop and specific application.

FAQ: Grain Conveyors

What are grain conveyors?

Grain conveyors are mechanical systems designed to transport bulk grains from one location to another. These conveyors can be belt, bucket, or screw types, each suitable for different grain handling scenarios, from loading to processing to storage.

How do mechanical conveyors differ from other types of grain handling equipment?

Mechanical conveyors, specifically designed for grain handling, are built to handle large volumes of grains efficiently. Unlike manual handling or pneumatic systems, mechanical conveyors provide a continuous, controlled flow of grain, which helps in maintaining the quality and reducing the handling time.

What are the advantages of using a grain belt conveyor?

A grain belt conveyor offers numerous advantages including gentle handling of grains to prevent damage, high efficiency in moving large volumes, and the ability to transport grains over long distances. They are also adaptable to various configurations and can include features like adjustable speed and reversible direction.

Can mechanical conveyors be used for both small and large-scale operations?

Yes, mechanical conveyors are highly versatile and can be tailored to suit both small and large-scale operations. The design and capacity of the conveyor can be customized to match the specific requirements of the operation, ensuring optimal efficiency and effectiveness.

What types of grain conveyors does Kongskilde offer?

Kongskilde offers a variety of grain conveyors, including mechanical conveyor systems like grain belt conveyors, bucket elevators, and chain conveyors. Each type is designed to meet specific requirements in agricultural operations, ensuring efficient handling and transport of grains.

How does Kongskilde ensure the quality and efficiency of its mechanical conveyors?

Kongskilde ensures the quality and efficiency of its mechanical conveyors by using high-quality materials and state-of-the-art manufacturing processes.

Can Kongskilde customize grain conveyors for specific farming needs?

Yes, Kongskilde can customize grain conveyors to meet specific farming needs. Whether you need adjustments for different grain types, capacities, or physical layout constraints, Kongskilde works closely with clients to tailor conveyor solutions that optimize their operational efficiency and meet their unique requirements.

Contact us to start the conversation today.

Questions? Contact us, or find a dealer near you.