Paper Industries

Pneumatic solutions for the paper industry

Take your paper production to the next level with Kongskilde Industries’ pneumatic conveying solutions designed for the paper industry. Remove trim and waste, improve production efficiency, and keep your work environment clean using a pneumatic system.

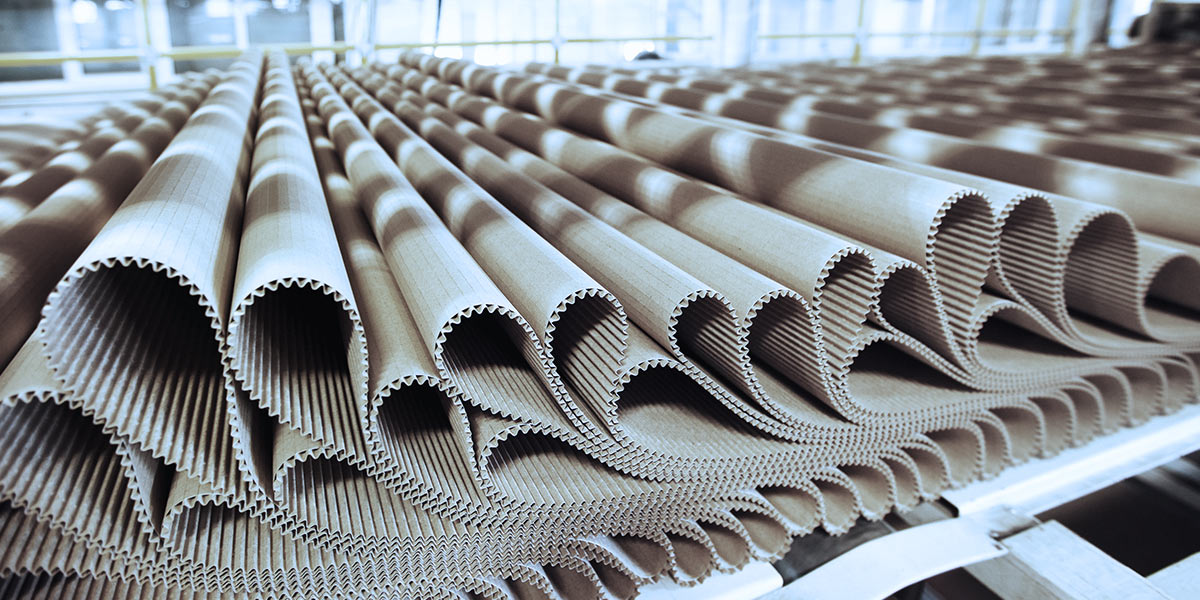

Cardboard Production

Remove and sort different types of corrugated paper and cardboard waste from your production with a Kongskilde Pneumatic Conveying Solution. Save space by mounting the flexible system where it fits your needs – there’s no need to use large areas for the installation of pipelines, grinders or blowers. The system also keeps your production hall comfortable and reduce the need for air conditioning by removing the excess heat generated by your production machines.

Related Applications

Carton Box Production

Remove waste from your box production quickly, easily and efficiently with a Kongskilde Pneumatic Conveying Solution. Save valuable space and resources by automatically removing waste from box flap cuts and transporting them away from your production. The system increases workplace safety and can also send re-heated, filtered air back into your production hall.

Related Applications

Label Production

Effectively remove label waste generated by modern label production machines, including endless trims, adhesive matrix waste and more. Keep your production running smoothly without the need to slow or stop your machines to remove the matrix waste roll. Remove process waste from building up around your machines and causing production downtime, increased operating costs, and taking up valuable floor space.

Related Applications

Paper Cup Production

Effectively remove trim and skeleton from the production of paper cups using a Kongskilde Pneumatic Conveying Solution. Save time by streamlining your production process and reduce the need for labour by automating the removal of excess trim and off-cuts. The solution can be adapted to your existing production set-up and configured to your exact needs and requirements.

Related Applications

Paper Production

Quickly remove trims from your manufacturing process, without the need to bale or compact on the production floor, with a Kongskilde Pneumatic Conveying Solution. Improve productivity by eliminating production bottlenecks associated with the removal of trims. Save energy and reduce the risk of accidents on your production floor by keeping the machinery environment clean.

Related Applications

Paper Roll Converting

Effectively remove trims from paper roll converting machines (slitters/re-winders) for repurpose and recycling. A Kongskilde Pneumatic Conveying Solution can gently remove trims from the production area and shred trims during conveying to save storage space. Excess material can be directed to multiple destinations to keep different materials separated.

Related Applications

Printing Houses

Effectively and efficiently remove paper and process waste from your production environment with a Kongskilde Pneumatic Conveying Solution. Increase visibility and safety, and prevent dust from contaminating your production by keeping flying dust and debris safely contained in the enclosed system. And with a Kongskilde solution, there’s no need to move or adjust your production set-up, all elements are designed to perfectly fit in your existing framework.

Related Applications

Tissue Production

Transport logs, cookies and continuous trims away from your tissue production quickly and easily with a Kongskilde Pneumatic Conveying Solution. Increase productivity and safety by keeping your production area free from waste and debris. And because tissue production generates lots of fine particles, a Kongskilde solution can be dimensioned with a high-performance air filter to effectively remove dust from the air.