Air / Material Separators

RVS/KS Rotating Separators

Rotating separator for removal of small size waste from production lines

RVS MultiSeparators are particularly suitable for installations where a strong suction effect is essential, such as the removal of light material from the suction line air stream.

KS separators are developed for the separation of cardboard and paper from the conveying air stream in both positive and negative pressure systems.

High-speed trim extraction for paper, plastic, and packaging

Production machines in the plastic, paper, and packaging industries are continuously developed to run at increasingly higher speeds, we have developed a system to keep up. An important factor to secure high production capacity is an efficient system to quickly remove excess material, such as fast-moving trim, from the production area.

In combination with Kongskilde’s standard range of modular components, the RVS-H and KS separators are the basis for extremely powerful energy-efficient extraction solutions capable of following the speed of today’s production facilities.

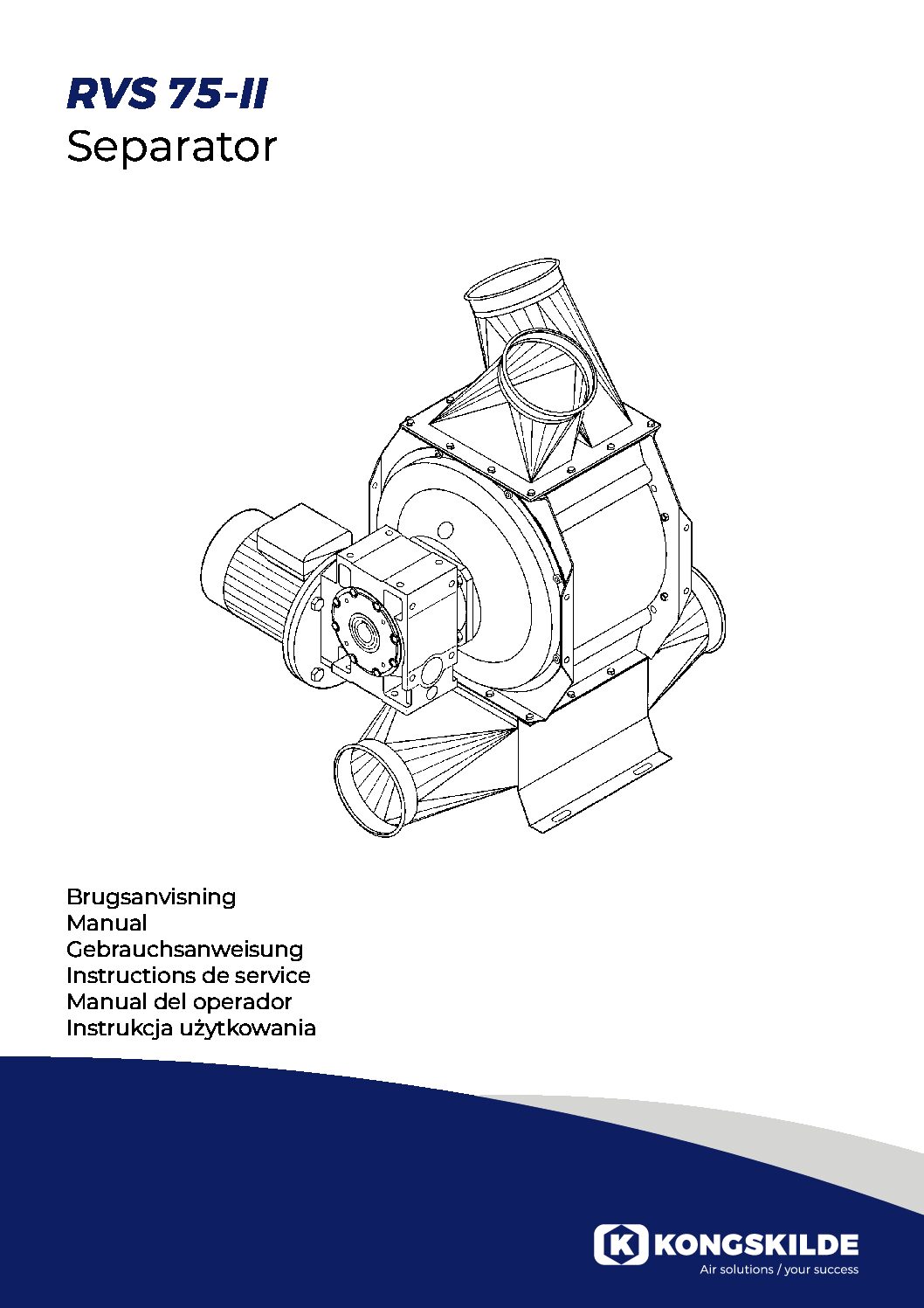

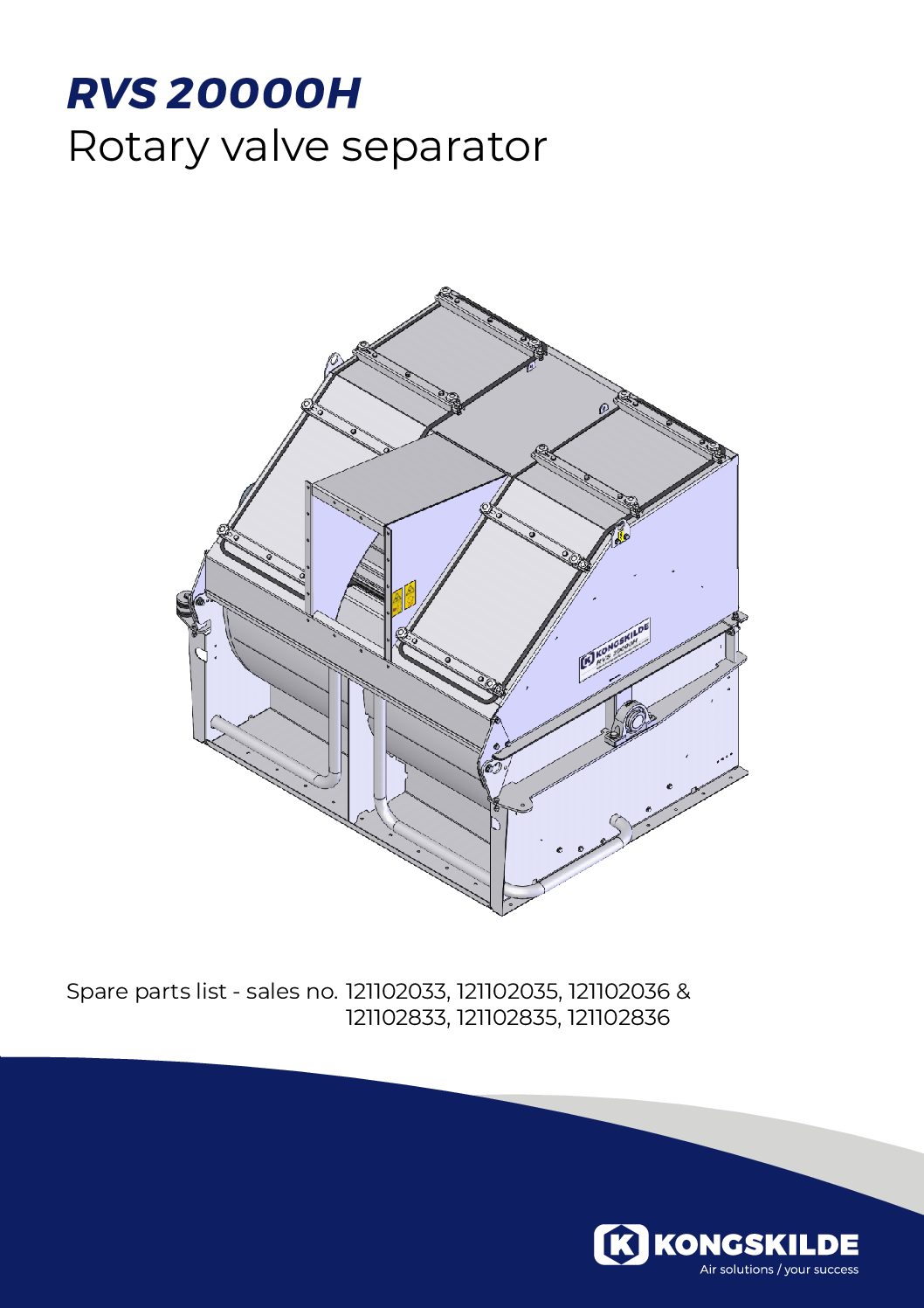

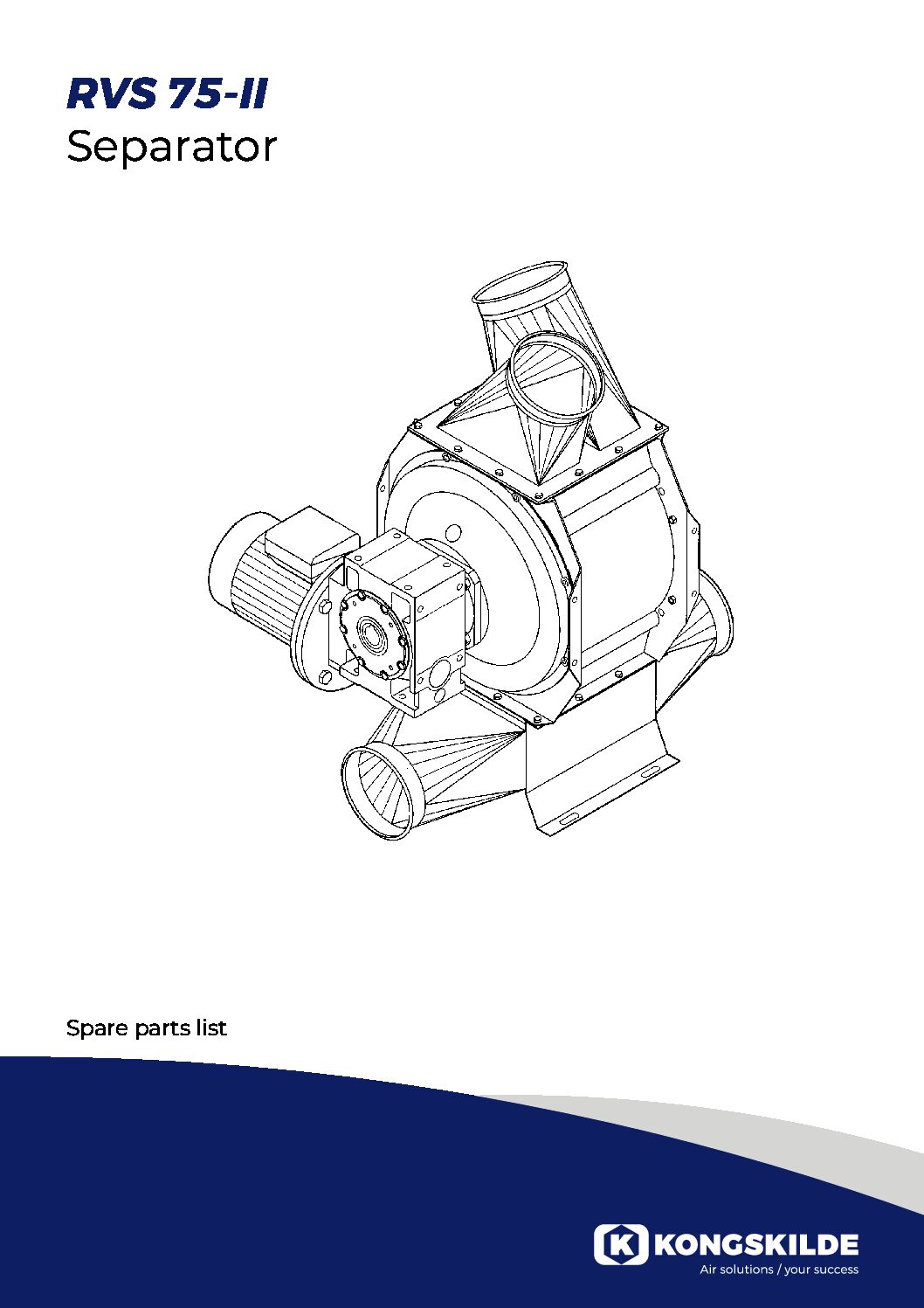

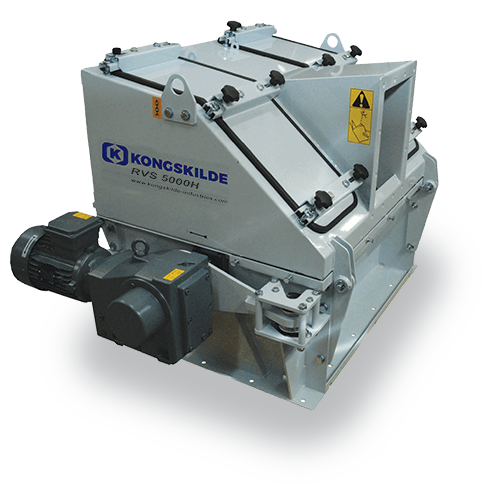

RVS MultiSeparator

The Kongskilde MultiSeparator range type RVS-H is developed for pneumatic waste handling systems in the plastic and paper industry. Specifically, producers with high production rates require high-performance suction power and have high material capacities.

- Separates light material from the suction line air stream efficiently.

- Particularly suitable for installations where a strong suction effect is essential.

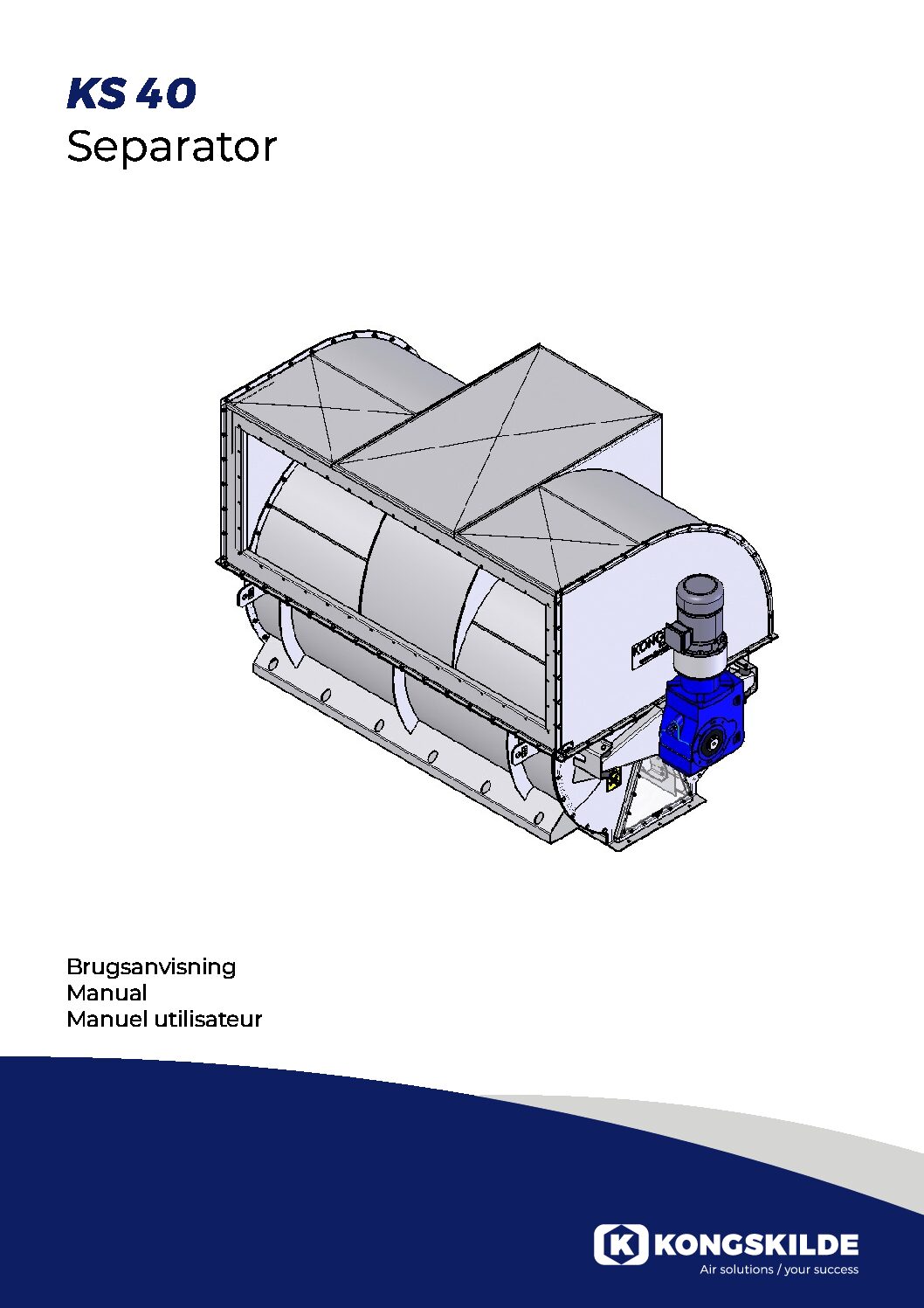

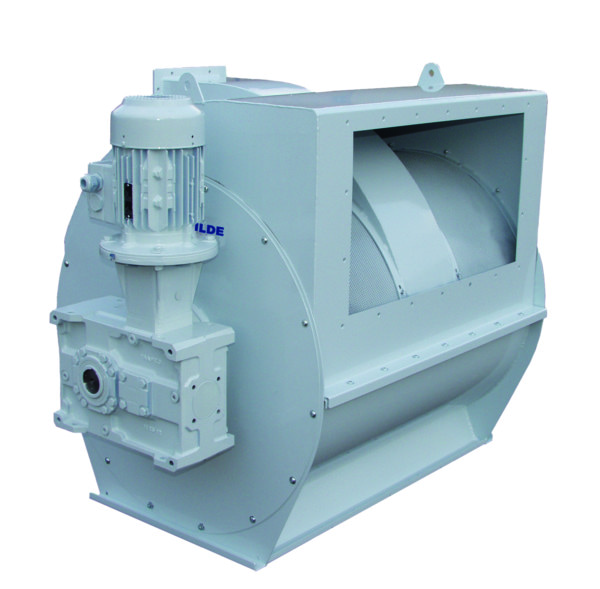

KS Separator

The KS separator ensures a low amount of pressure loss and material separation with minimal release of air. This allows the separator to be directly connected to a compactor or container.

- The KS separators are larger than the RVS and are developed only for the separation of cardboard and paper.

- Designed for conveying air in both positive and negative pressure systems.

Downloads

Download brochures, manuals, data sheets, and spare parts lists for the RVS / KS rotating separators (MultiSeparator).

Brochures

Data Sheets

Manuals

Spare Parts

RVS/KS Separator Model Comparison

Compare available RVS/KS models. Visit the downloads section for additional technical information.

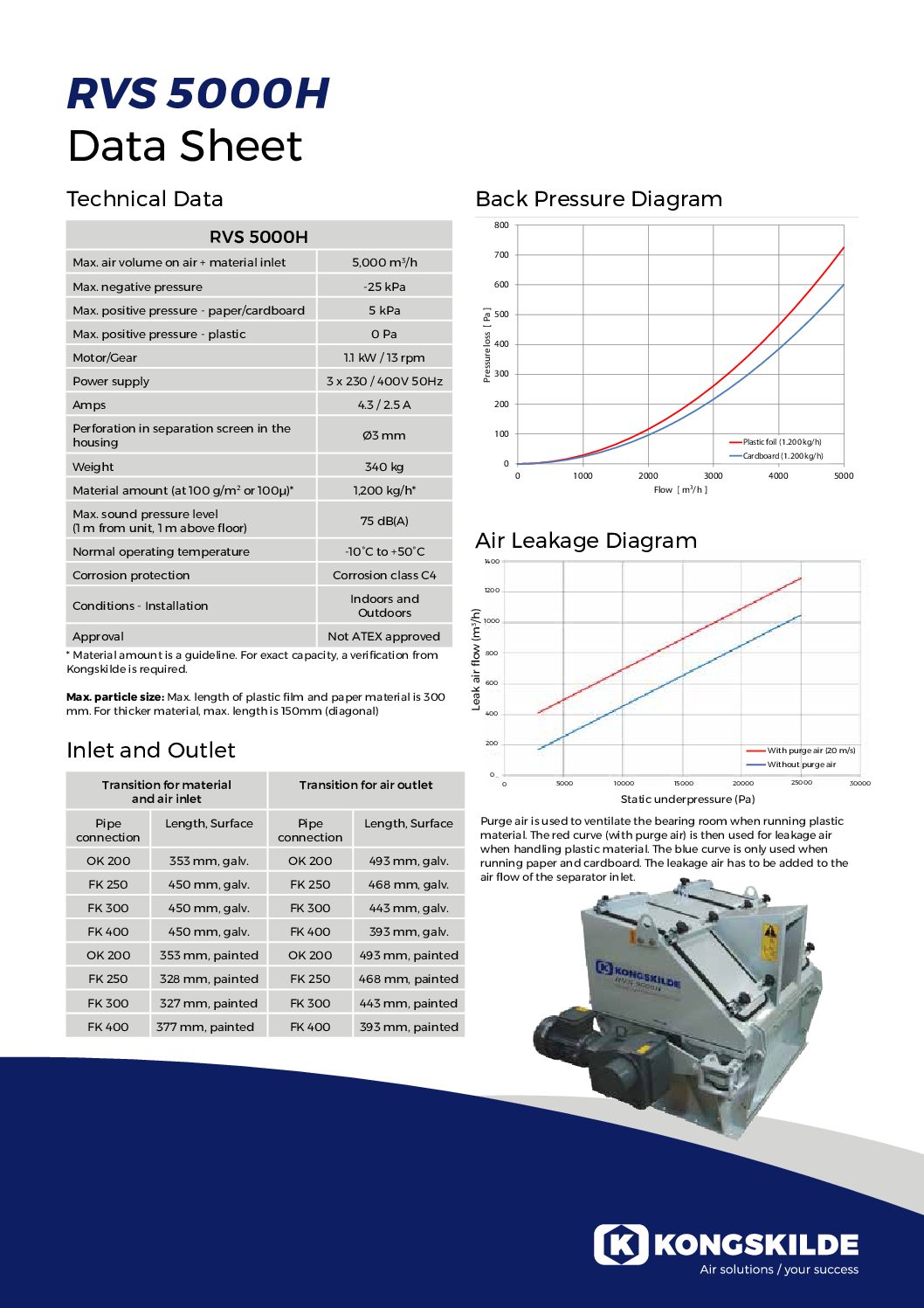

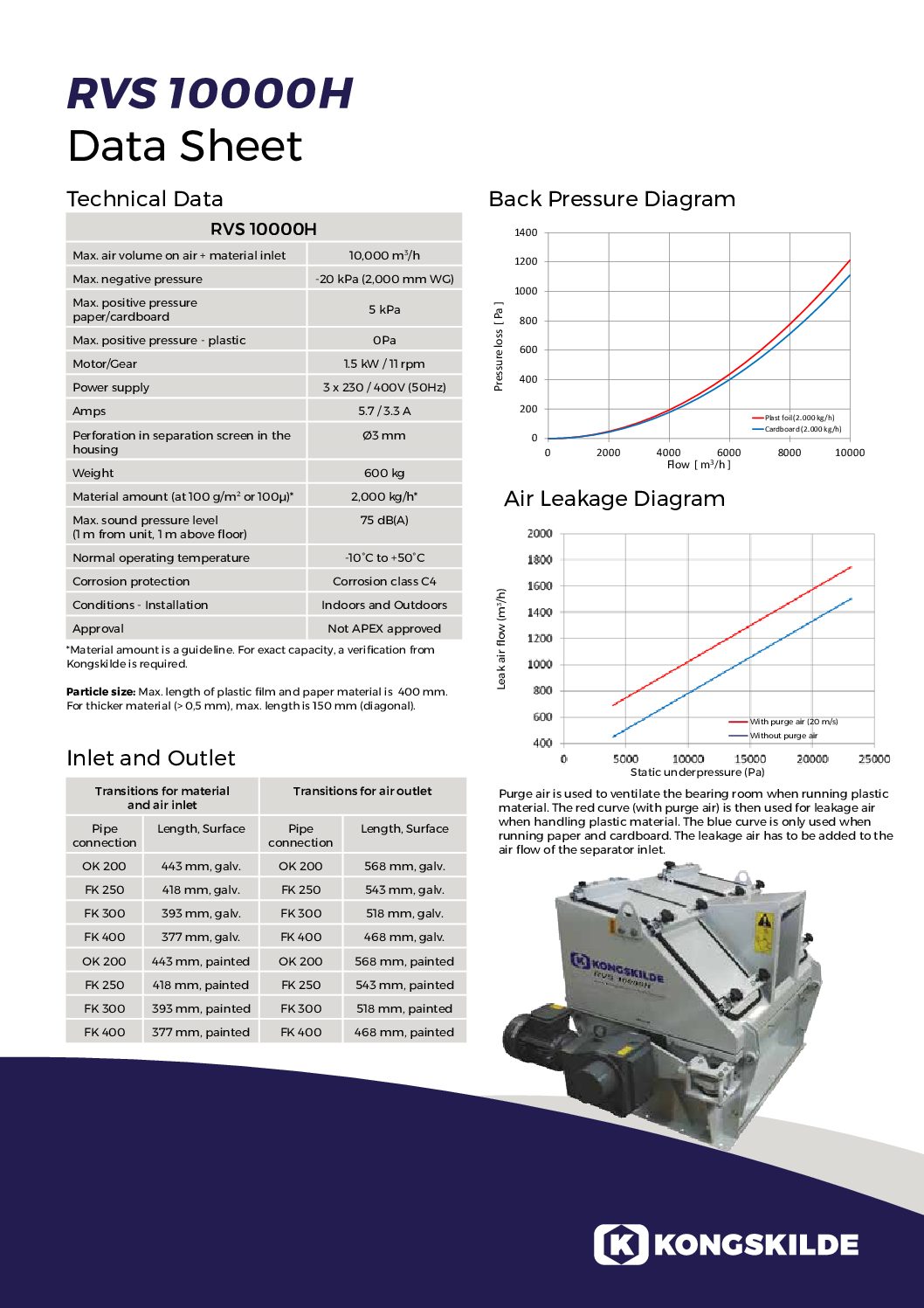

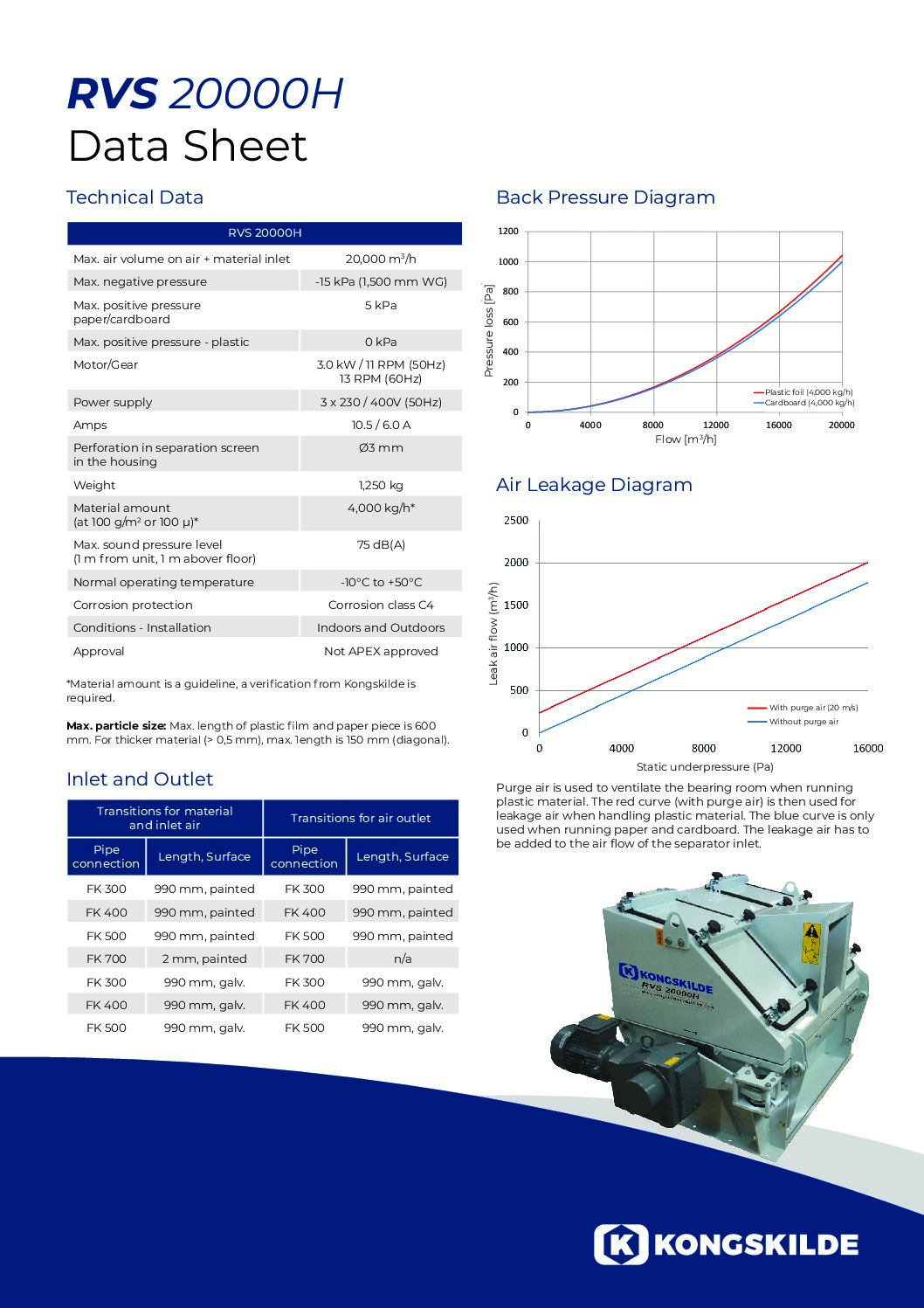

| RVS 75-II | RVS 5000H | RVS 10000H | RVS 20000H | KS 40 | |

|---|---|---|---|---|---|

| Material amount (at 100 g/m2 or 100μ)* | 300 kg/hr | 1,200 kg/h | 2,000 kg/h | 4,000 kg/h | 5,000 kg/h |

| Max. air volume on air + material inlet | 2500 m³/h | 5,000 m³/h | 10,000 m³/h | 20,000 m³/h | 40,000 m³/h |

| Max. negative pressure | 34 kPa | -25 kPa | -20 kPa (2,000 mm WG) | -15 kPa (1,500 mm WG) | 3.5 kpa |

| Max. positive pressure | N/A | 5 kPa | 5 kPa | 5 kPa | 3.5 kpa |