Downsizing Cutters & Granulators

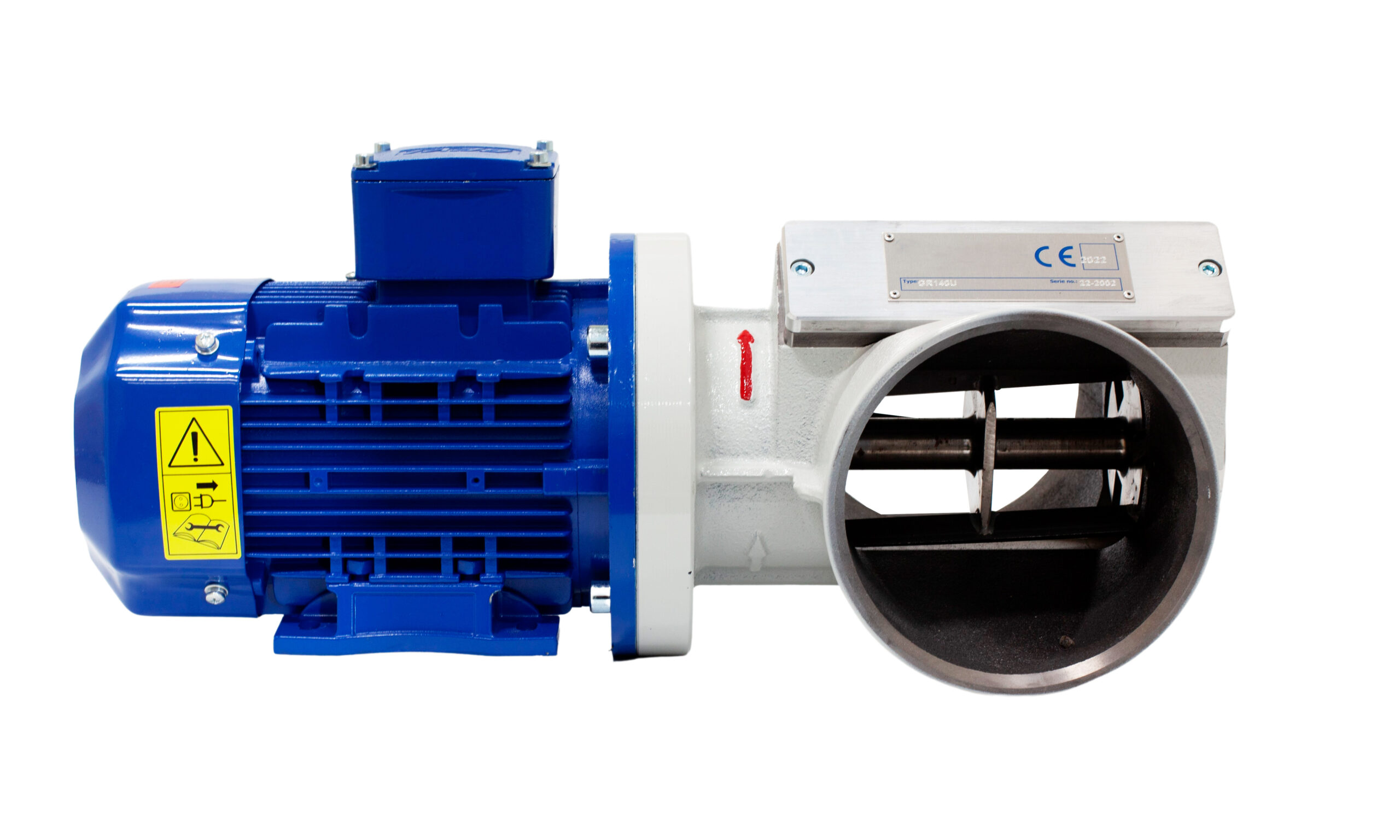

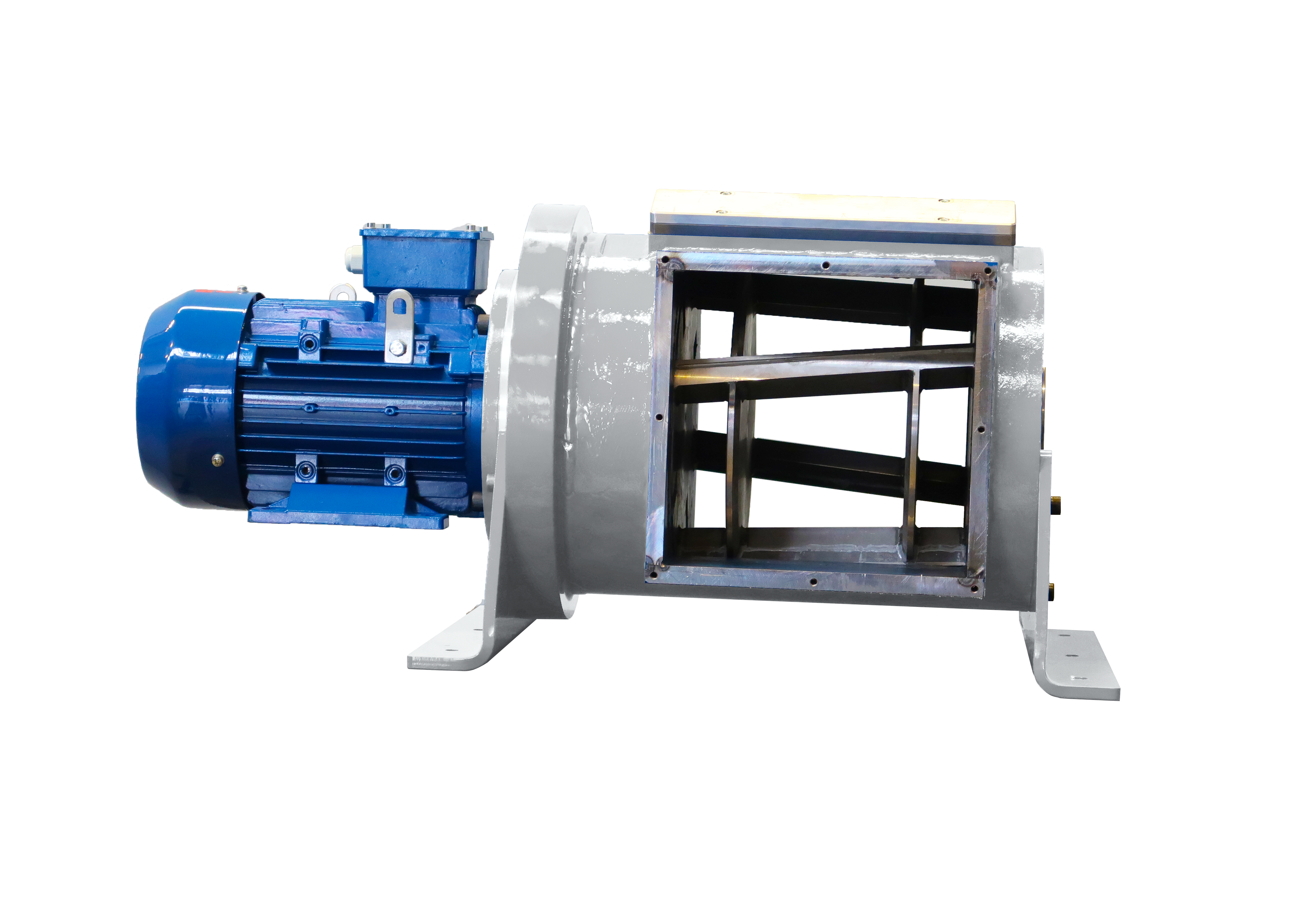

MultiCutter MCC

Developed for continuous cutting of process waste for almost any application.

The MCC cutters can be connected to pipe sizes from Ø80mm to Ø400mm, allowing for air amounts up to 10,000 m3 per hour. The airspeed through the cutter can be as fast as 80 m/s, permitting process machine speeds up to 2,500 m/min.

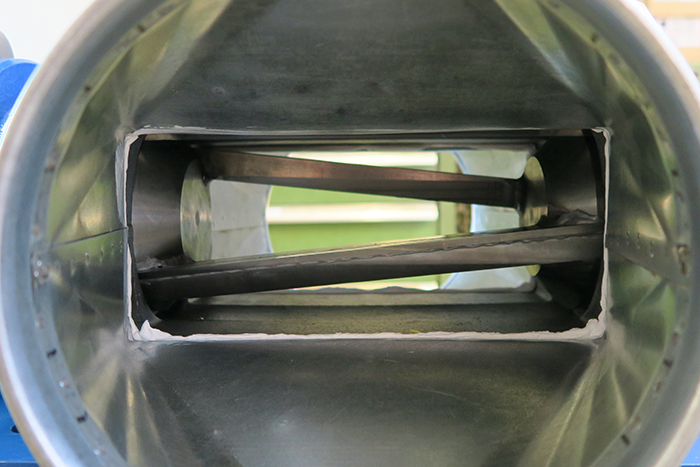

The opening entrance of the cutter can be as wide as 660mm allowing it to cut very wide and stiff materials. Cutters for cutting ultrathin materials down to 5 microns are also available. The standard MCC Cutters have a rotor with 3 knives and a direct coupling to a motor with 1,400 or 2,800 rpm.

Efficient cutting in pneumatic systems

The complete MCC-Series of granulators and cutters are all of the highest quality standards and assure our customers of maximum cutting efficiency.

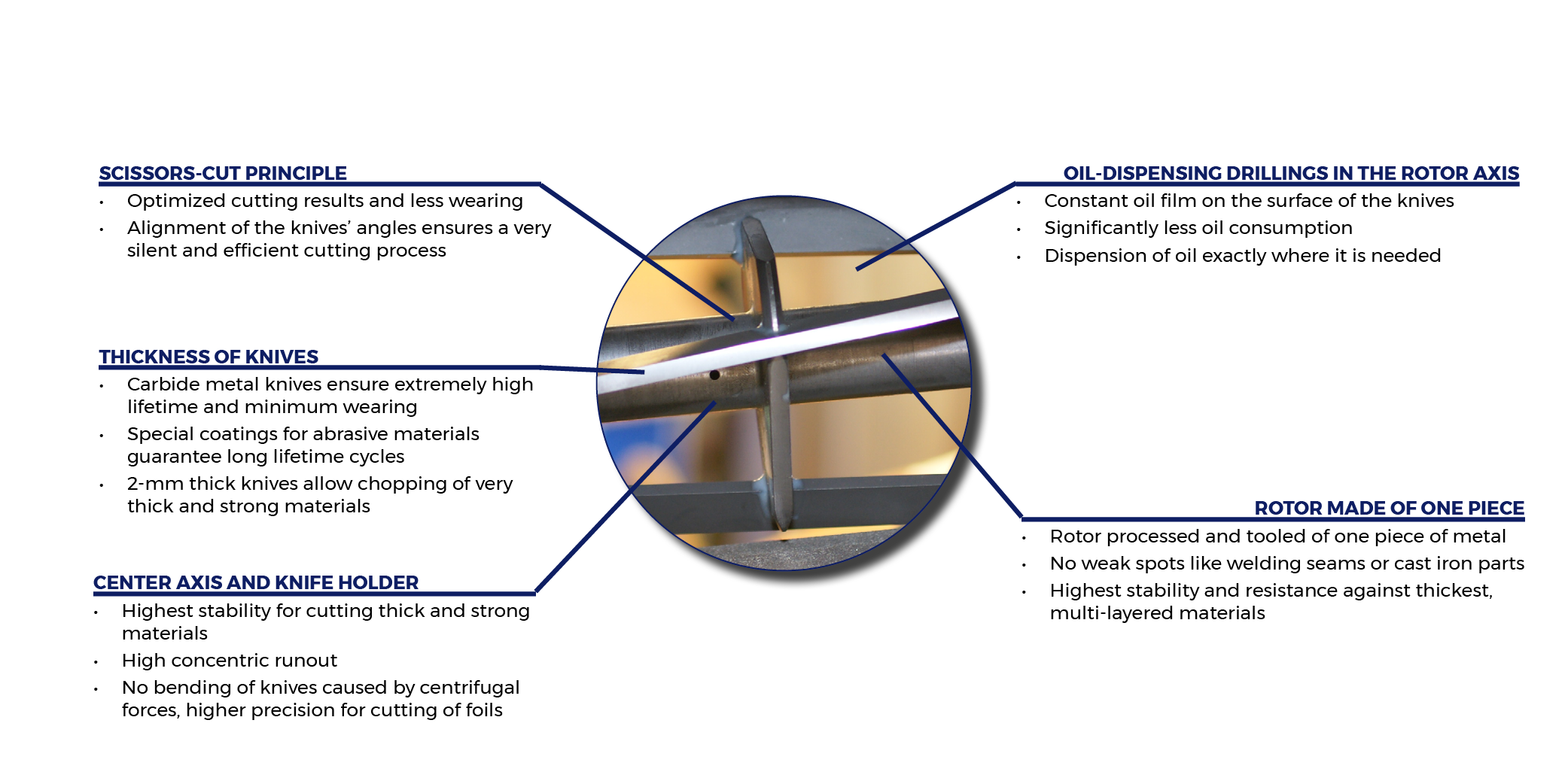

Highlights

- Reduced volume of waste by cutting the waste

- High cutting efficiency

- Prepare for recycling

- Ability to cut very thin materials, down to 5 microns

- Easy to adjust, multiple screws for adjusting the fixed blade

- Construction with high stability

- Lubrication system without compressed air

- Special composites of hard metal and cutting knives

- Low maintenance costs

- Very long lifetime: Granulators more than 25 years old are still operating

- Broad product line with entrance from 55-660 mm and number of knives from 2-12 on the rotor

Downloads

Download the brochure with specifications for the Kongskilde MultiCutter MCC-Series.

MCC Cutter Model Comparison

Visit the downloads section for additional technical information.

|  |  |  | |

|---|---|---|---|---|

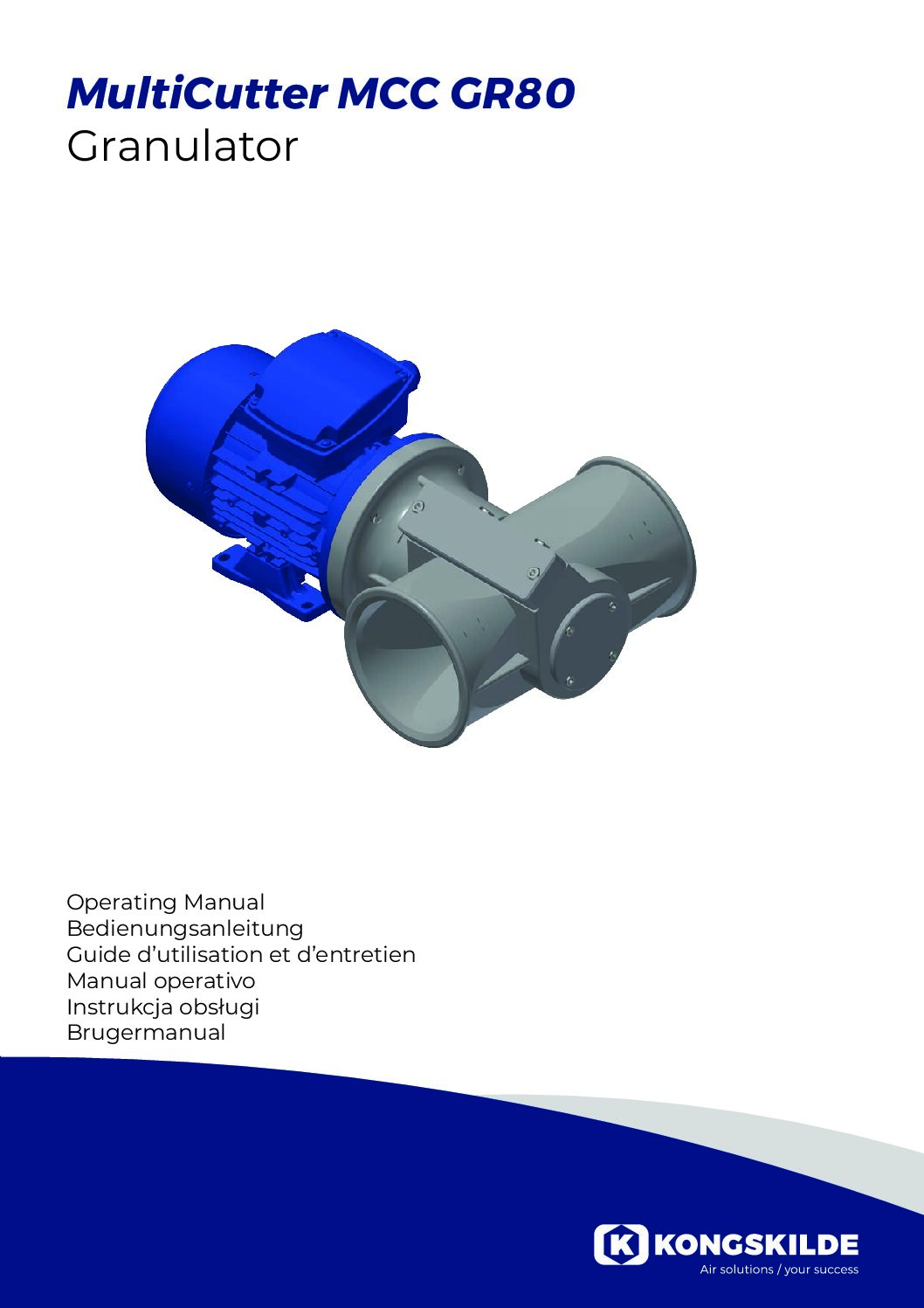

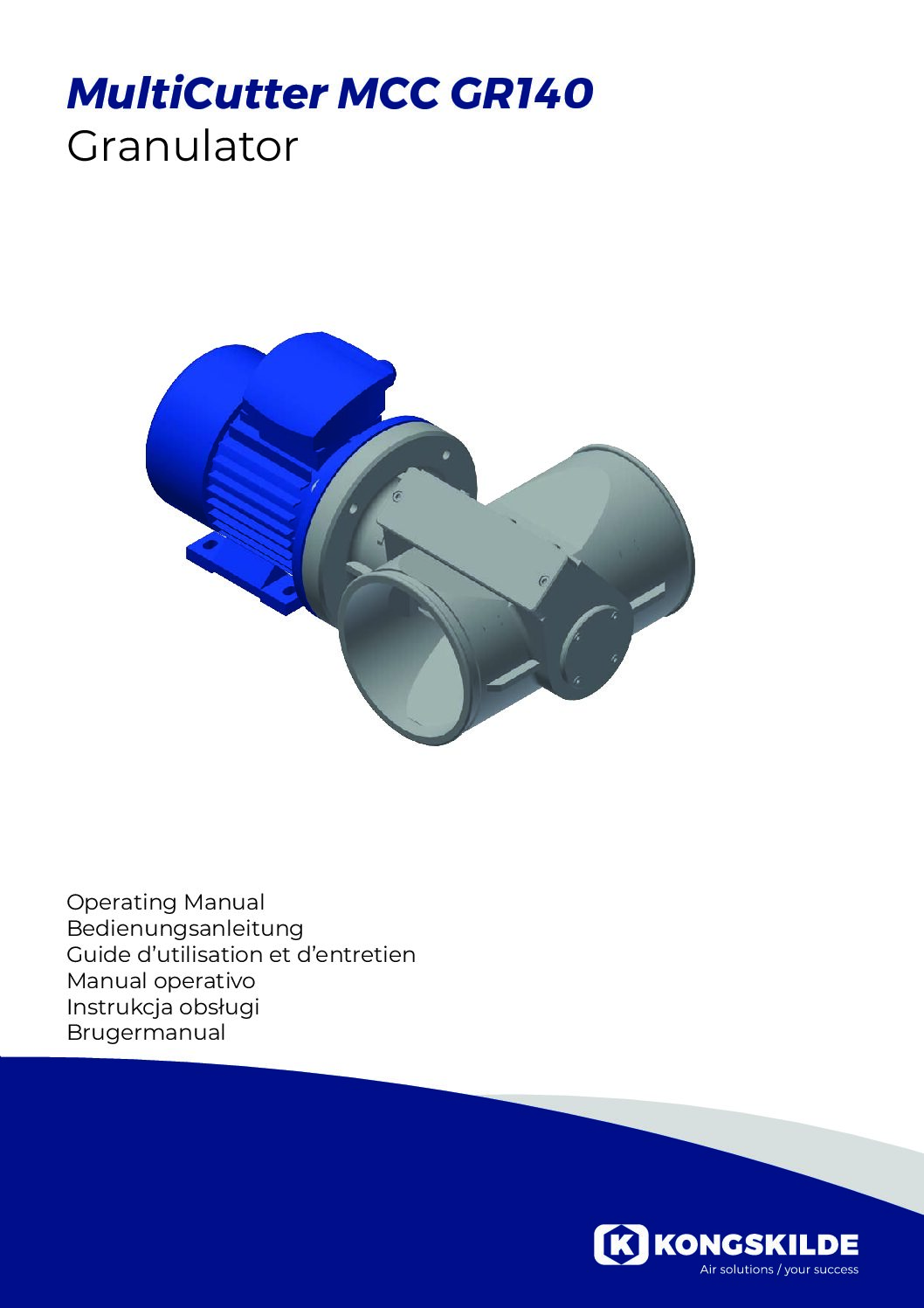

| GR 80 | GR 140 | GR 200 | GR 250X | |

| Material Thickness minimum in microns | 20 | 10 | 10 | 20 |

| Housing | Hard-metal | Hard-metal | Hard-metal | High-carbon steel |

| Motor standard | 0.55 kW (0.74 HP) type M71 1,400/2,800 rpm | 0.75 kW (1 HP) type M80 1,400/2,800 rpm | 1.5 kW (2 HP) type M90 1,400/2,800 rpm | 3 kW (4 HP) type M100 1,400/2,800 rpm |

| Nom. amperage Amp | 1.2 | 1.75 | 3.5 | 6.3 |

| Piping Ø mm | 125 (5″) | 160 (6″) | 160-250 mm (6″-10″) | 200-400 mm (8″-16″) |