The Challenge

The Danish Municipality collects plastic, metal, and glass from households and sorts them before sending them to a recycling plant where its reused.

- The Municipality faced efficiency and health challenges because the employees getting injuries due to the many twists and turns of their bodies when handling the different plastic containers and various sizes of glass and jars coming from the households.

- The solution should contribute to a faster and more efficient sort and both improve the working environment and minimize sickness leave so that the facility can sort even more HDPE, PET, and mixed plastic waste, metal, and glass.

- For the Municipality it was also essential to achieve a cleaner recycling facility worth showing to the people of the municipality.

The Solution

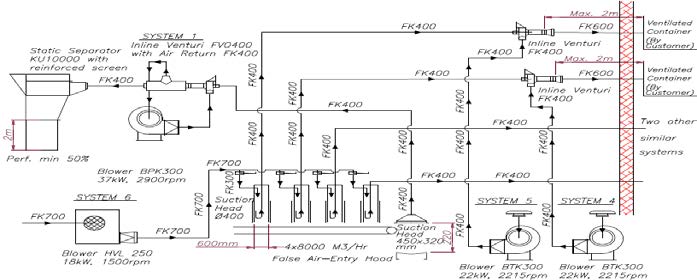

- Kongskilde implemented four FVO 400 Venturi units with air-return operated with four BTK 300 blowers to convey waste from a size sorting unit to the central sorting belt conveyor. In this process, glass was sorted out by gravity as one of the Kongskilde Venturi systems was sucking all the light items from the edge of the conveyer belt and conveying it to a KU static separator discharging the material to the next belt conveyor.

- The solution includes three suctions heads just above the conveyor belt improving the worker’s physical work environment by reducing the number of daily turns.

- The material from the suction heads is sucked in Ø400 piping to ITF 400 Venturi systems, from where it’s blown into containers which are transported to the recycling plant.

The Advantages and Benefits

- The Kongskilde solution increases efficiency, eliminates poor working positions and movements, and even saves one person in the working staff.

- The environment of the recycling plant is cleaner as dust from the waste is now eliminated creating a healthier working environment and minimizing the maintenance of the production facility.

- To prevent a draft that could influence the worker’s health every suction point is mounted with a false air supply to make the room neutral.

- The system is able of handling 2,000 tons of household waste every year. The Kongskilde part is sorting 277 tons of waste every year saving time, money, and labor.

The Facts

- Material: PET, HDPE and Mixed plastic

- Requested solution: customer needed to sort and convey the plastic items to be transported to outside containers for recycling

- Suction points: 5

- Size: Ø400 mm diameter

- Flow: 277 tons every year

- Conveying distance: H: max 25m. V: max 5 m. 5 x 90 degree bends