The Challenge

This international company is headquartered in the Netherlands and is well known for its wall coverings.

- The conveying solution has to deliver an adequate vacuum to secure gentle transport of the wallpaper trim.

- The system is equipped with in-line cutters, and fire protection shutters on walls to meet local fire regulations.

- The system must pass through a fireproof barrier and contribute to the overall fire protection in the production.

- A filter has to remove any dust from the air before it is released outside.

The Solution

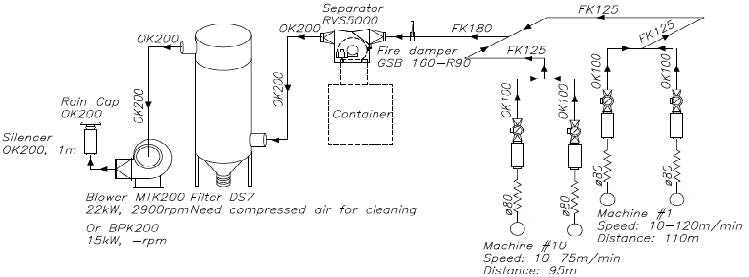

- The Kongskilde solution consists of two MultiCutters, the RVS-5000 Separator and BKP 200 blowers, DS 7 Filter unit, and the firebreak STFR PCMTB R 90 unit to ensure high productivity without risk of fire.

- As the system passes a fireproof barrier, special fire dampers were installed, suited for handling systems where products are going through main pipes. The fire damper needs dry air, so an air dryer was added.

- The system generates a fast and powerful conveying of the trim material from the production lines through the MultiCutters to the rotating separator (RVS 5000), which is placed on top of the waste containers for easy handling.

The Advantages and Benefits

- The Kongskilde solution is highly flexible due to its modularity for quick setup of the pneumatic conveyor solution, even for special requirements such as fire protection and filter for clean air.

- The system generates a fast and gentle conveying of the trim material and secures high productivity without creating dust in the production facility and easy and cost-effective removal of the waste.

- The system is equipped with in-line cutters, which allows more machines in one central system even though the trims are not running at the same speed.

The Facts

- Material: Wallpaper

- Trim width: 20 mm

- Number of machines: 1 (75 m long, 5,5 m wide and 7 m high)

- Suction points: 2 pickup points

- Speed: 120 m/min.

- Material specifications: Paper: 80-180 g/m2, Suede/textile: 450 g/m2, Flice: 60-150 g/m2.

- Conveying distance: H: 120 m V: 10 m with 6 bends

- Fire protection: The fire dampers needed high-quality air (dry) so there was installed an air dryer