The Challenge

- A multinational consumer goods company has a factory in Europe for filling and capping bottled products.

- Two capping machines apply various kinds of caps for bottles. The caps are stored in boxes in the basement underneath the 1st floor where the capping machines are in operation.

- Before installation of the pneumatic system, a pallet with boxes of 2,500 pcs. was moved one pallet at a time between

the floors by a forklift and elevator. - The company needed a solution that would relieve the operator from having to cut open boxes and lift them to pour caps into the capping machine and also avoid the use of forklift and elevator.

- The company requested a system that would cut away the logistics of having a forklift operator transport pallets back and forth to save time and increase safety.

The Solution

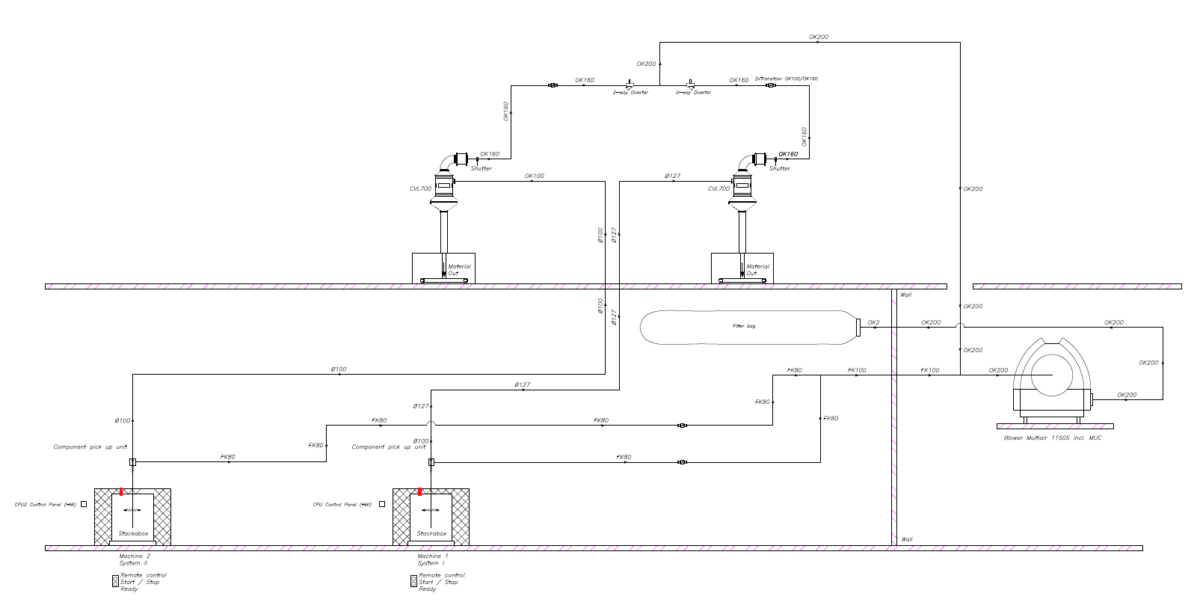

- 2 pcs. Component Pick-up Units (CPU)

- 2 pcs. Component Vacuum Loaders (CVL)

- Piping, up to 50 metres

- Blower, MultiAir FC 1100

The Kongskilde solution includes two Component Pick-Up Units (CPU), specially selected plastic piping with smooth surface to avoid scratching of component surfaces, a blower (MultiAir FC 1100 S), and two Component Vacuum Loaders (CVL) for batch delivery in the production.

Each CPU empties the containers in the basement at the rate of 10,000 caps per hour. When emptied, the CPU goes into standby, the forklift operator exchanges the container, and presses start. The factory runs 24/7 in three shifts.

The CVLs deliver the caps at the required rate of 10,000 pcs. per hour to the capping machines.

The Advantages and Benefits

- The seamless combination of the Pick-Up Unit and the Component Loader streamlines the transfer of plastic components from the warehouse to capping production lines.

- The pneumatic conveying and batch delivery on a large scale of components is fast and efficient.

- Processes that used to be manual are now automated.

- The conveying system is flexible as it goes both horizontally and vertically, leaves a small footprint, and is gentle to the plastic components.

- The solution heightens safety as the forklift no longer goes back and forth alongside the production lines.

- Work is now more ergonomically correct for the operator.

The Facts

- Material: Bottle caps

- Dimensions, diameter: Up to 80 mm

- Material weight cap: Up to 8 g/m2

- Quantity: +10,000 caps per hour per line

- Machinery: Two capping machines