The Challenge

This Spanish lollypop producer is part of a worldwide company producing confectionary products.

The customer has 4 process machines producing endless trims of waste when packing lollypops. The trims were collected in small binds next to the machine and that created 3 main problems:

- The time and labour costs needed to handle and remove the waste were too high. The removal of waste required a forklift. This created a liability issue in the production area.

- The look of the production environment with trim waste laying in waste containers was not representative whenever the customer received guests.

- There was a negative impact on the productivity caused by the accumulated waste around each machine.

- The company needed a waste solution that could keep the production area clean and increase production efficiency due to minimal line stops.

The Solution

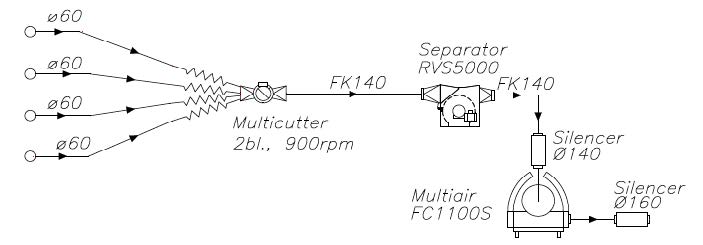

- The pneumatic solution implemented is the well-proven Kongskilde RVS 5000 system combined with the new FC MultiAir 1100S and one MultiCutter. The pipeline is the flexible OK 160 system and the solution is easy to upgrade

- High flexibility and the modularity means easy setup of the pneumatic conveyor solution which can be accomplished in hours. The pipes mounted in the ceiling liberates space

- The solution generates a significant low extraction airflow for every machine

The Advantages and Benefits

- The Kongskilde solution increased productivity as the customer no longer has to stop the machines to empty the waste bins where the endless trims used to be collected.

- Downtime has been reduced by 1.5 hours by automatic and continuous transfer of waste directly out of the production facilities to an outside container.

- Labour cost related to manual waste handling inside the production and adjacent areas has been reduced by 25 %. The liability related to the forklift is no longer a concern.

- More space around the machines improves productivity.

- The factory environment is cleaner as waste is no longer collected in bins around the machines.

- Due to the vertical piping design and use of stainless steel pipes the customer can now perform wet cleaning regularly inside and outside on our trim suction piping.

- Pay-back time is expected to be less than 10 months.

The Facts

- Material: Silicon paper, endless trim

- Number of machines: 4 pcs

- Number of endless trims: 1 pcs per machine

- Max. trim width: 20 mm

- Max. trim speed: 225 m/min.

- Material thickness: 30-100 g/m2

- System specifications: Conveying distance: 100 m + 6 x 90°