The Challenge

This German company is the market leader in stamping machines and delivers to clients around the world.

- The handling of the edge trims affects productivity. It is a complicated process to handle the edge trims from a hot foil stamping machine. The setup is a tedious process that requires human intervention, and the rolls have to be changed during production at long runs.

- The trim is usually rewinded onto individual rolls after the stamping process and has to be removed manually.

- The customer wants a 24/7 production since it is costly and takes time to set up each production line.

- In this case, the customer will have up to 15 endless trims in one production which complicates the situation even more.

- There is always a risk that extraordinary thin trim ends up in the machines and not on the rewind rolls which entails an emergency stop and a skilled workforce to sort the trim that caused a stop.

The Solution

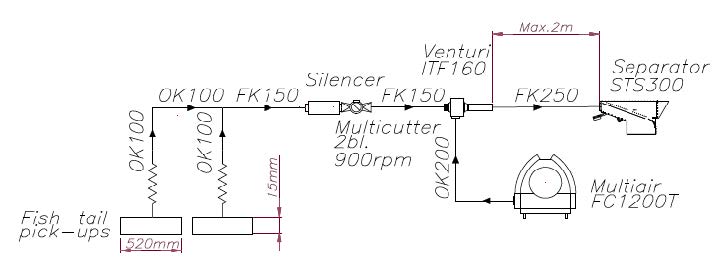

With the MultiAir® FC 1200T and the ITF 160 Venturi, up to 15 edge trims are sucked up. The endless trim is conveyed further in two OK 100 flex hoses conveyor lines. Both OK 100 conveyor lines are transferred to a standard FK 150 conveyor line. The trims are cut by a MultiCutter and end up in an STS 300 static separator.

The Advantages and Benefits

- The Kongskilde solution increases productivity as the customer eliminates manual labour on setup and later removal of the full rolls with edge trims.

- As there is no longer a need for the installation of rewinders for the carrier material, the machine setup time is reduced by as much as half.

- The reduction of unproductive labour time provided with the automatic and continuous transfer of edge trim directly out of the production facilities to an outside container also minimizes the liability related to the transport of full rolls by forklift through the plant.

- The noise reduction contributes to a better working environment.

- Since the rewinding is eliminated, there are fewer manufacturing faults. Production costs are reduced considerably and productivity had increased.

- Pay-back time is expected to be less than ten months.

The Facts

- Material: Hot foil, endless trim

- Number of machines: One

- Number of endless trim: 15 pcs.

- Pick-up: Two

- Max trim speed: 3210 m/h

- Max trim width: 15 mm

- Material thickness: 21 μ

- System specifications: Conveying distance: 40 m