Conveying Blowers

MultiAir Blowers

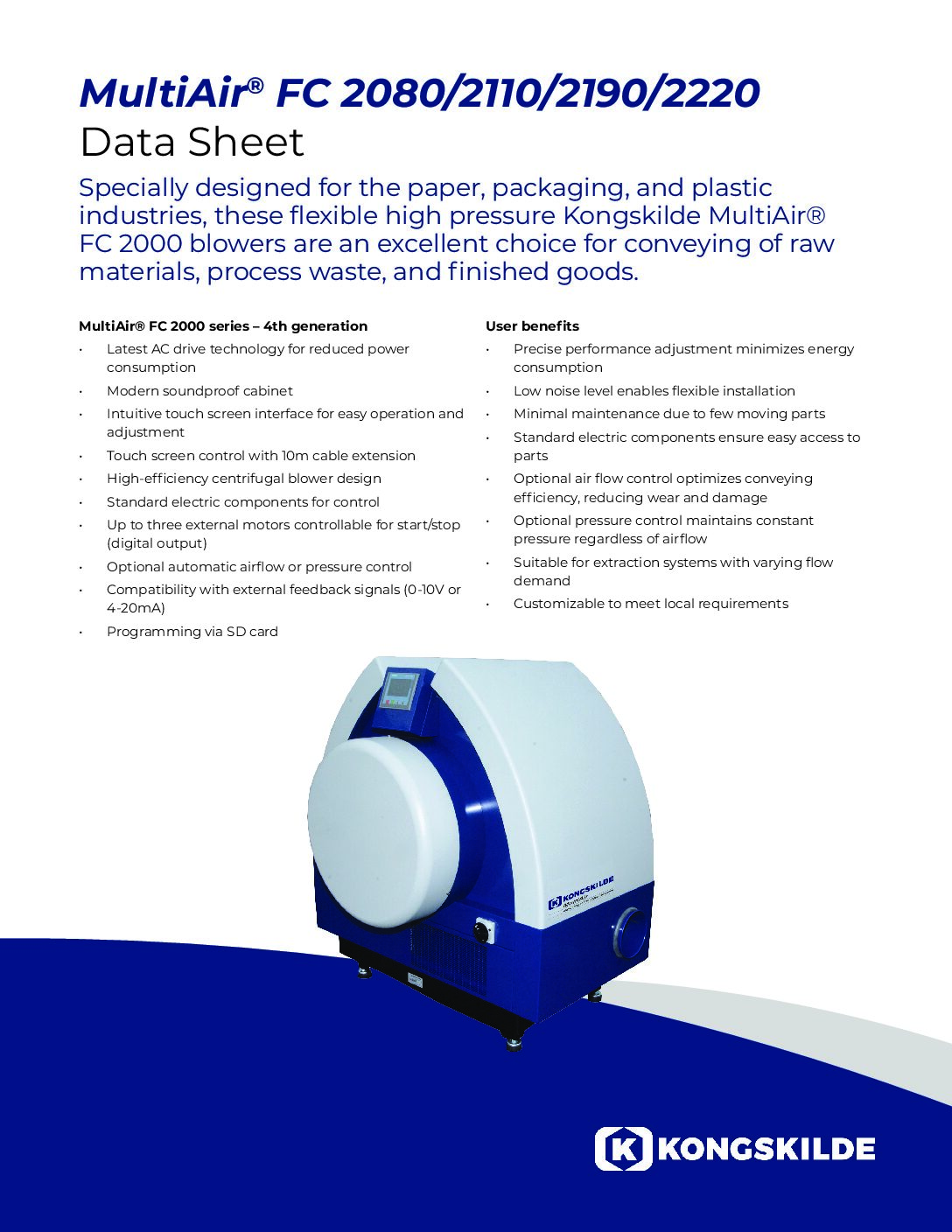

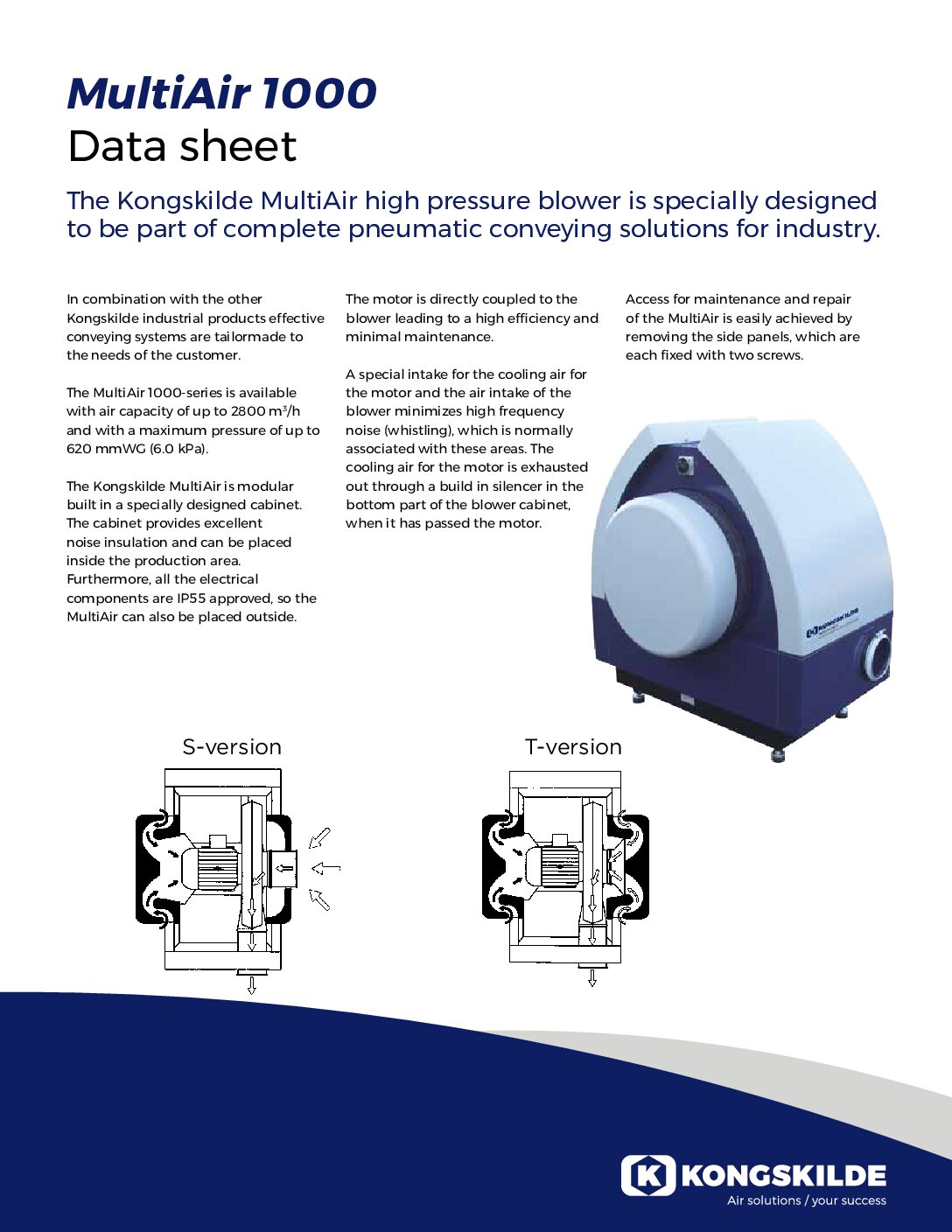

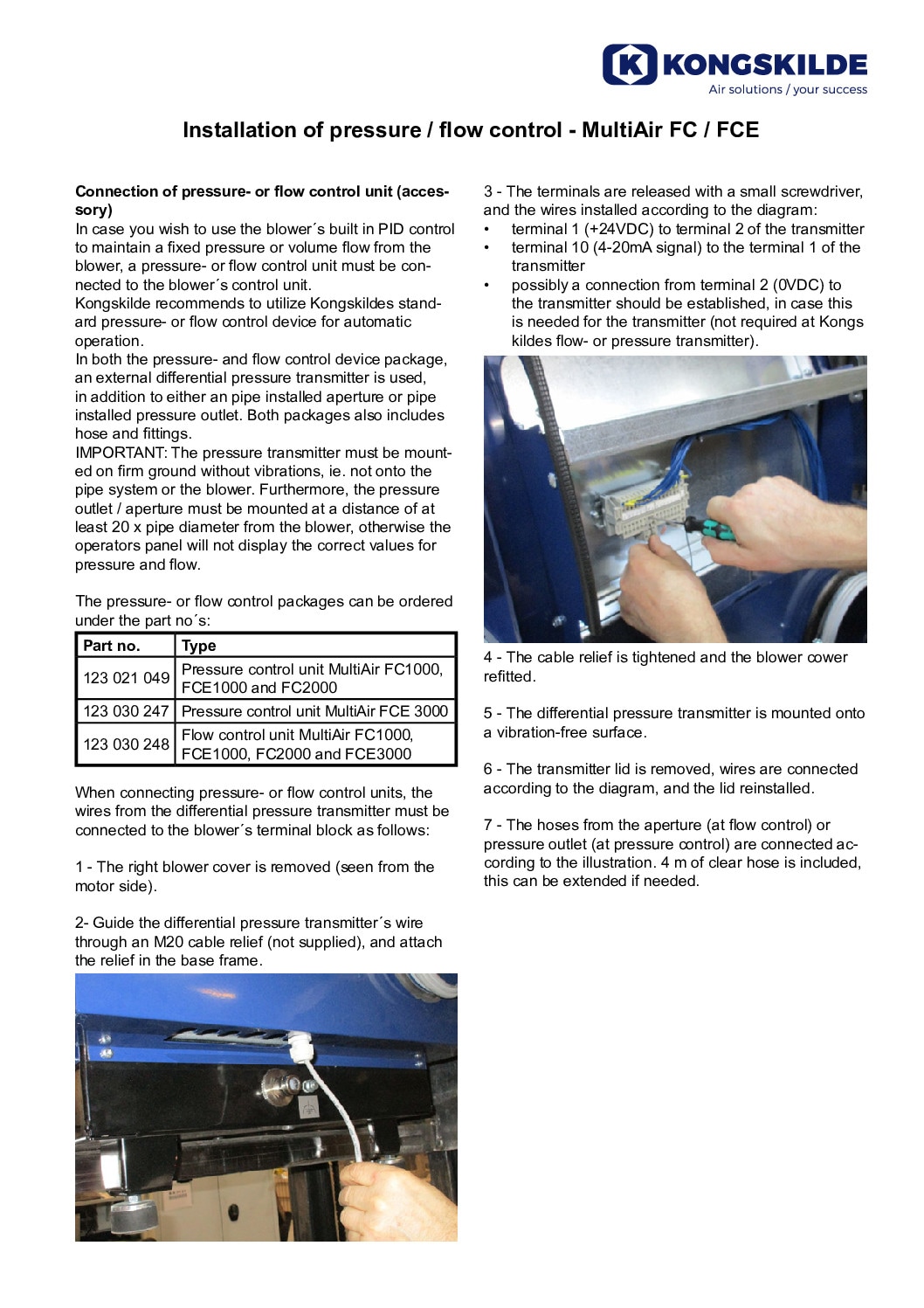

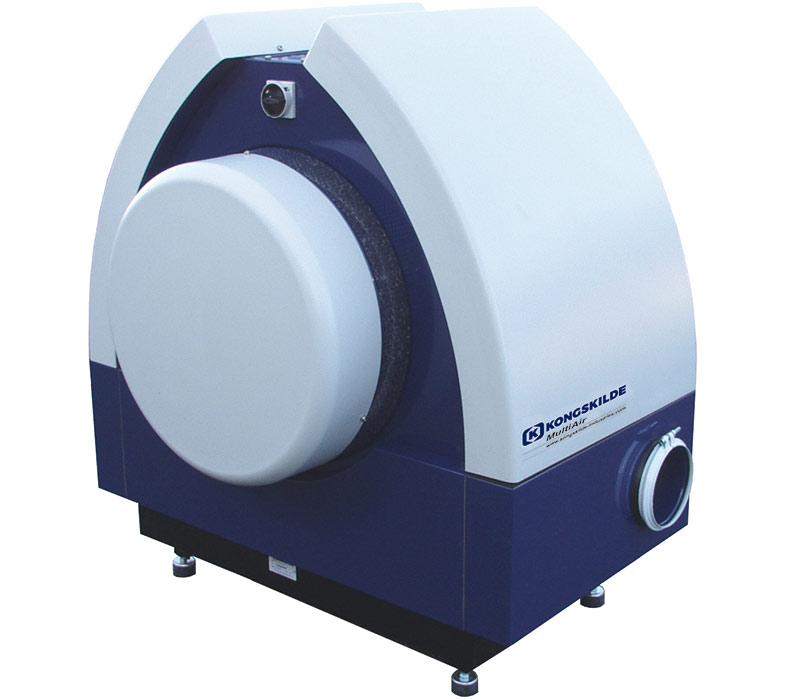

High-pressure conveying blower with a low noise level for pneumatic systems

Kongskilde offers robust and efficient high-pressure blower solutions ideal for diverse industrial applications.

Our MultiAir® series, including the cutting-edge MultiAir 4000, combines high performance with very quiet operation, offering unmatched benefits for production environments that demand precision and reliability. The MultiAir is a quiet, compact, and weatherproof unit. These unique features allow the blower to be positioned flexibly, both inside and outside the production area.

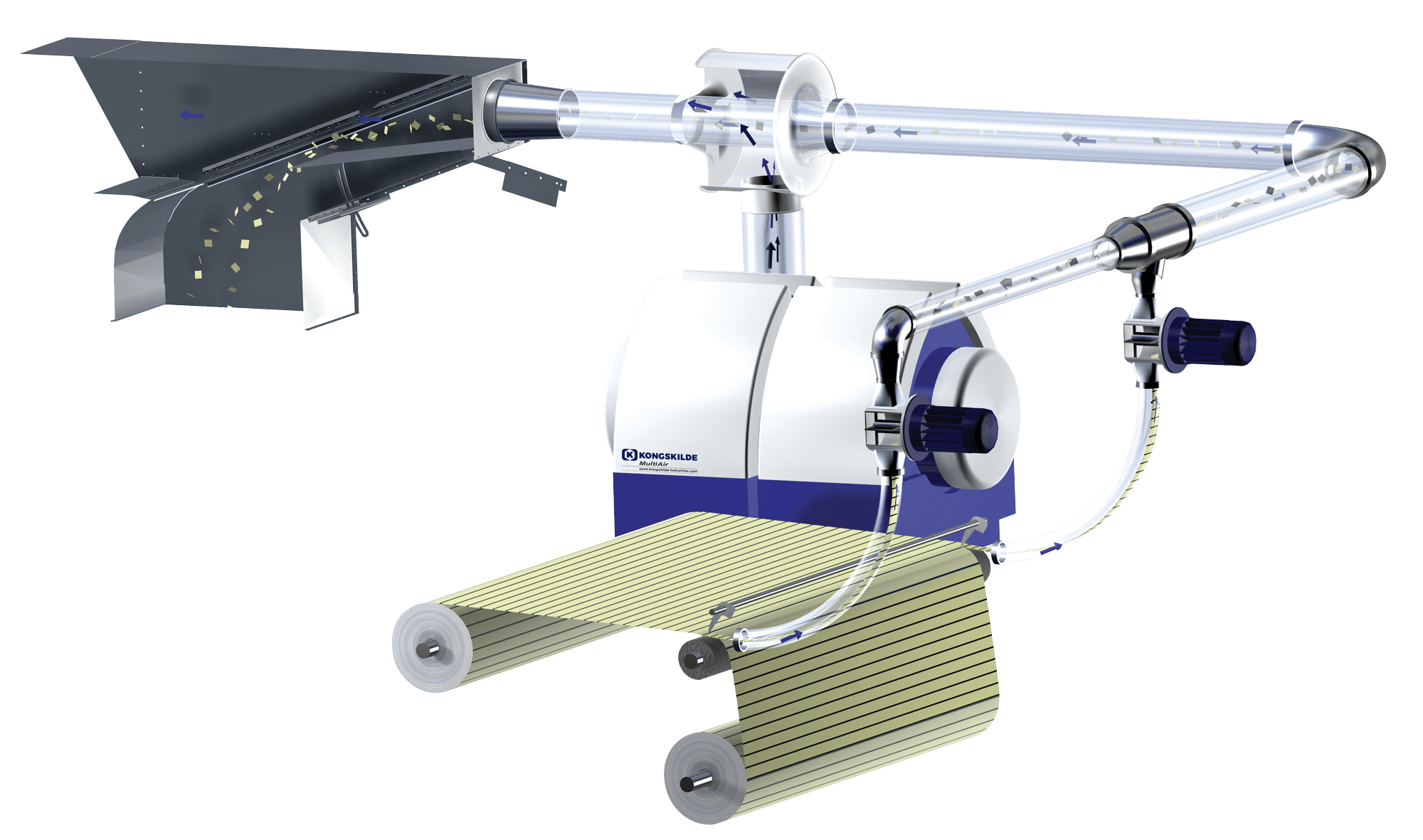

How Kongskilde MultiAir Blowers Work

High-pressure blowers from our MultiAir series are engineered to move air at high speeds, facilitating efficient pneumatic conveying. Designed for seamless integration into your existing setups, these systems ensure effective material handling with steady, dependable airflow.

Key Benefits of MultiAir Blowers

- Efficient Operation: Optimized for energy conservation, capable of transporting various materials over long distances.

- Low Maintenance: Fewer moving parts mean reduced upkeep and a longer lifespan.

- Flexible Installation: Compact and weatherproof designs allow for placement indoors or outdoors, adapting to your spatial needs.

- Quiet Performance: Specially engineered for low-noise operation, suitable for environments where noise is a concern.

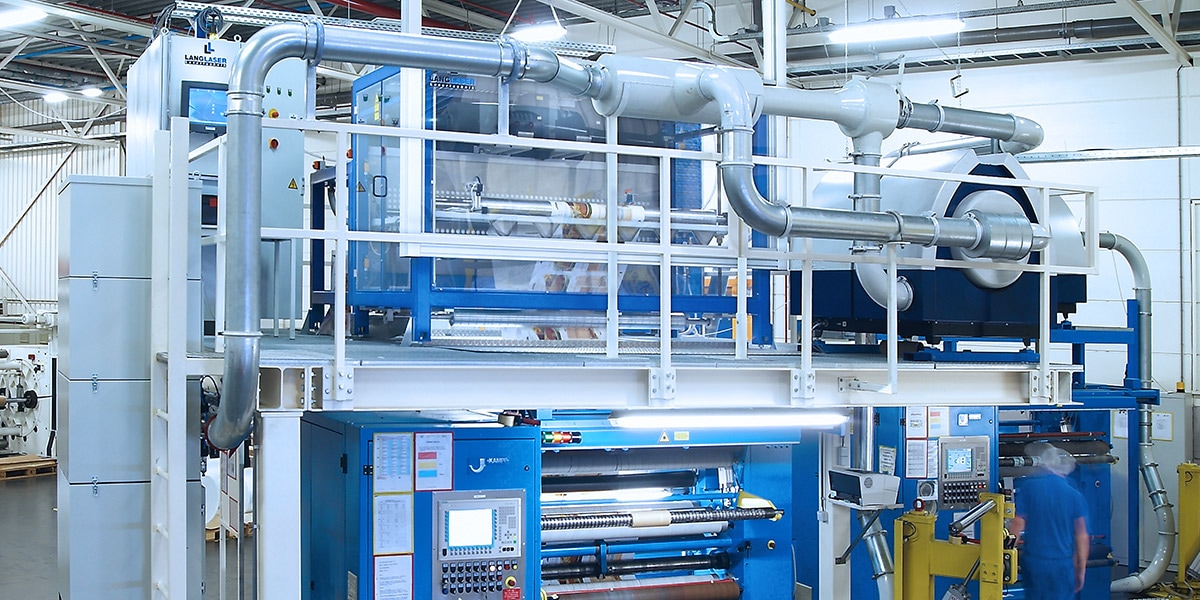

Applications of Kongskilde High-Pressure Blowers

Kongskilde’s high-pressure blowers are versatile and used across several industries, including:

- Plastics and Packaging: For conveying shredded materials and granulates.

- Printing Industry: Effective management of paper trim, foils, and other by-products.

- Manufacturing: Useful for handling injection molded parts and finished components.

- Waste Management: Efficient in trim and waste removal during recycling processes.

For businesses in need of powerful and reliable pneumatic solutions, Kongskilde’s MultiAir series stands out with its blend of innovation and performance. Contact our experts today to learn how our high-pressure blowers can enhance your operations.

The New MultiAir 4000

The largest and latest addition to the MultiAir blower family is the high-capacity MultiAir 4000. The MultiAir 4000 is engineered to meet the demand for increased performance and higher pressure levels. It is the perfect solution for high-volume trim removal and for large pneumatic systems that include venturis or separators.

About the MultiAir 4000

The MultiAir® 4000 series is a new generation of high-efficiency high-pressure blowers, which are very reliable, save power, have a low noise level, and have low maintenance requirements. As standard, the 4000 series is equipped with the same type of control with frequency converter as the MultiAir® FC 2000 series.

The new MultiAir® FC 4000 series of blowers are available in two product ranges, each with different motor sizes, and has the ability to move air with or without material through the blower.

The “P” range is a clean air blower for carrying particles, which can be used in systems for handling air not containing material. The “M” range is for carrying small, light materials—such as paper and plastic foil—and allowing them to pass through the blower.

“We like the blowers because they have a unique product line. The MultiAir is really quiet. High end companies don’t want noise and they seek products with noise reduction.“

President, Leading Manufacturer of Innovative Bulk Material Handling Solutions

Variable Speed Control

The MultiAir 4000 features a frequency converter that controls the speed and torque of the electric motor for variable speed control

Built-in Control Panel

The blower can be operated remotely using the built-in control panel and the manual control can be positioned inside or outside of the blower

Adjustable performance

Adjust performance to ensure minimized energy consumption or for systems with varying flow demand

Improved Environment

Very low noise level, built-in controls, and easy access to the blower create an optimal working environment

Downloads

Download brochures, manuals, data sheets, and spare parts lists for the MultiAir blower. For wiring diagrams, please contact us.

Brochures and Data Sheets

Manuals

Spare Parts

Compare MultiAir Models

Compare available MultiAir series models. Visit the downloads section for more information on specific models.

|  |  |  | |

|---|---|---|---|---|

| MultiAir 1000 | MultiAir FC 2000 | MultiAir FCE 3500 | MultiAir 4000 | |

| Max. output power (kW) 50 Hz | 1.5 – 5.5 | 7.5 – 22 | 22 – 37 | 22 – 55 |

| Rated current 400 V | 3.4 – 11.1 | 25-63 | 39-65 | 63 – 100 |

| Motor (rpm) | 2900 | 0 – 4800 | 0 – 4800 | 0 – 3600 |

| Frequency converter built into the blower cabinet | NA | Available for ambient temp. -10 to 50°C | NA | Available for ambient temp. -10 to 50°C |

| External converter panel | NA | NA | Available for ambient temp. -10 to 50°C | NA |

| Number of control boxes for optional connected equipment motors (separate timer on each) | NA | 3 | 1 | 2 |

Videos

Learn more about the Kongskilde MultiAir blower and see it in action in the videos below.

MultiAir Applications

The MultiAir is suitable for a wide variety of applications such as conveying shredded material, granulates, injection molded parts, finished components, and endless film, foil, or paper trim.