Products

Filter

By Type

By Industry

By Application

Effectively captures angel hair and streamers in vacuum and pressure conveying systems.

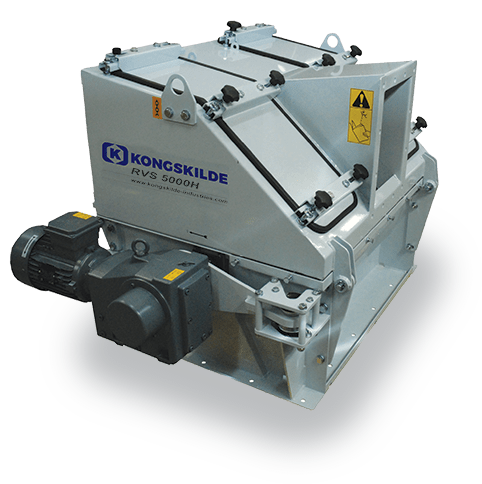

A compact and mobile machine-side collection unit for cutting and extracting process waste

Inline cutting unit for processing continuous and endless waste materials with low noise.

The K-Series bag filter is a modular dust collection unit ideal for indoor installations.

Rotating separator for removal of small size waste from production lines.

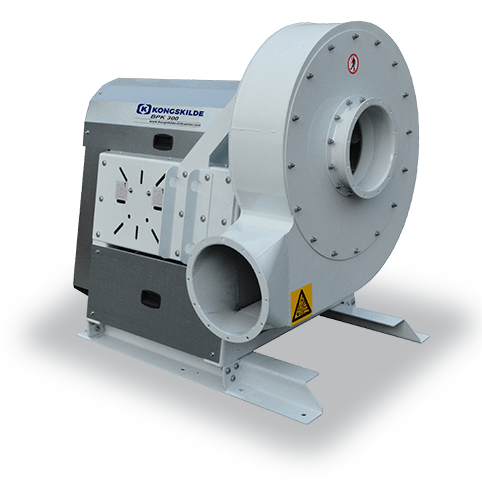

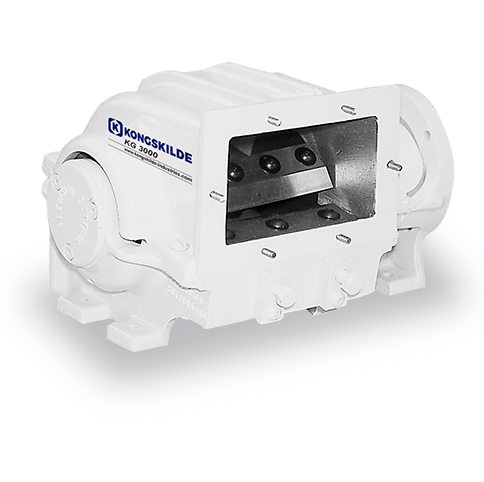

Directly and indirectly coupled centrifugal units for the handling of material through the blower.

For separation of material from conveying air at material outlet points in pneumatic conveying lines.

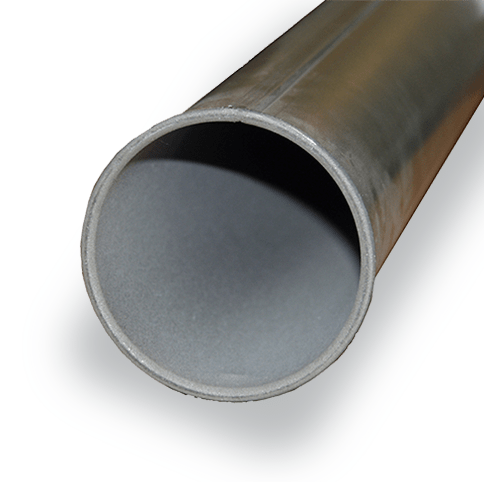

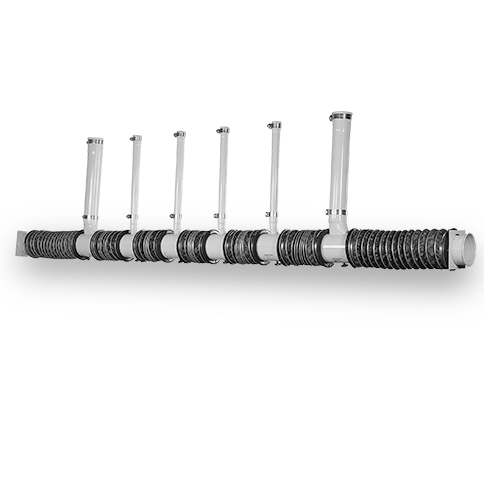

Stainless steel pipe system for pneumatic conveying or other air evacuation systems.

Neutralizes statically charged materials to eliminate clogs in pneumatic conveying systems.

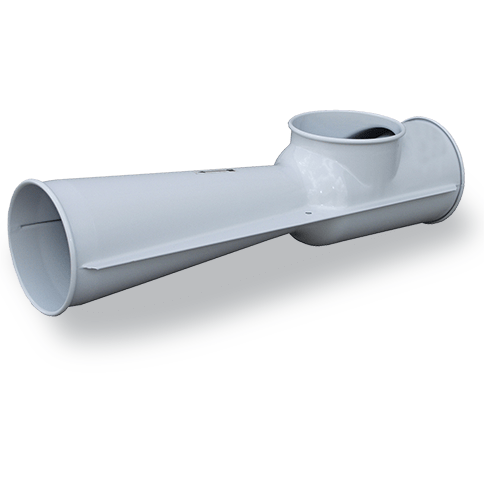

For conveying material through a duct without coming into contact with any moving parts.

Granulator for plastic foil which allows process waste to be reused in production.

The KIV is paired with the ITF venturi to improve suction and airflow in a conveying system

For continuous cutting of waste edge trim from machines for film blowing, packaging, paper production and slitters.

Flexible solution for efficient trim extraction in the paper and plastic converting industries

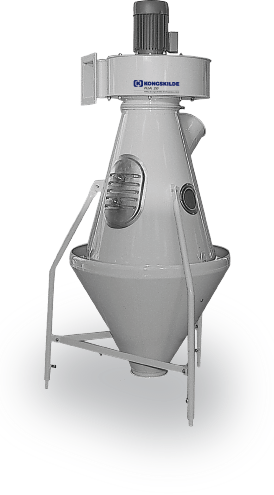

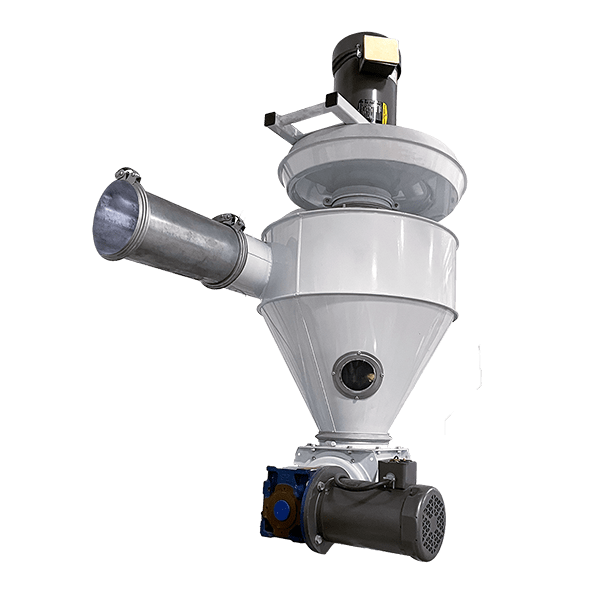

A combined blower and cyclone designed for high capacity suction conveying.

Industrial System Applications

Explore applications that utilize the Kongskilde line of products. Whatever your application, Kongskilde can deliver a high-performance solution that adds value to your production.