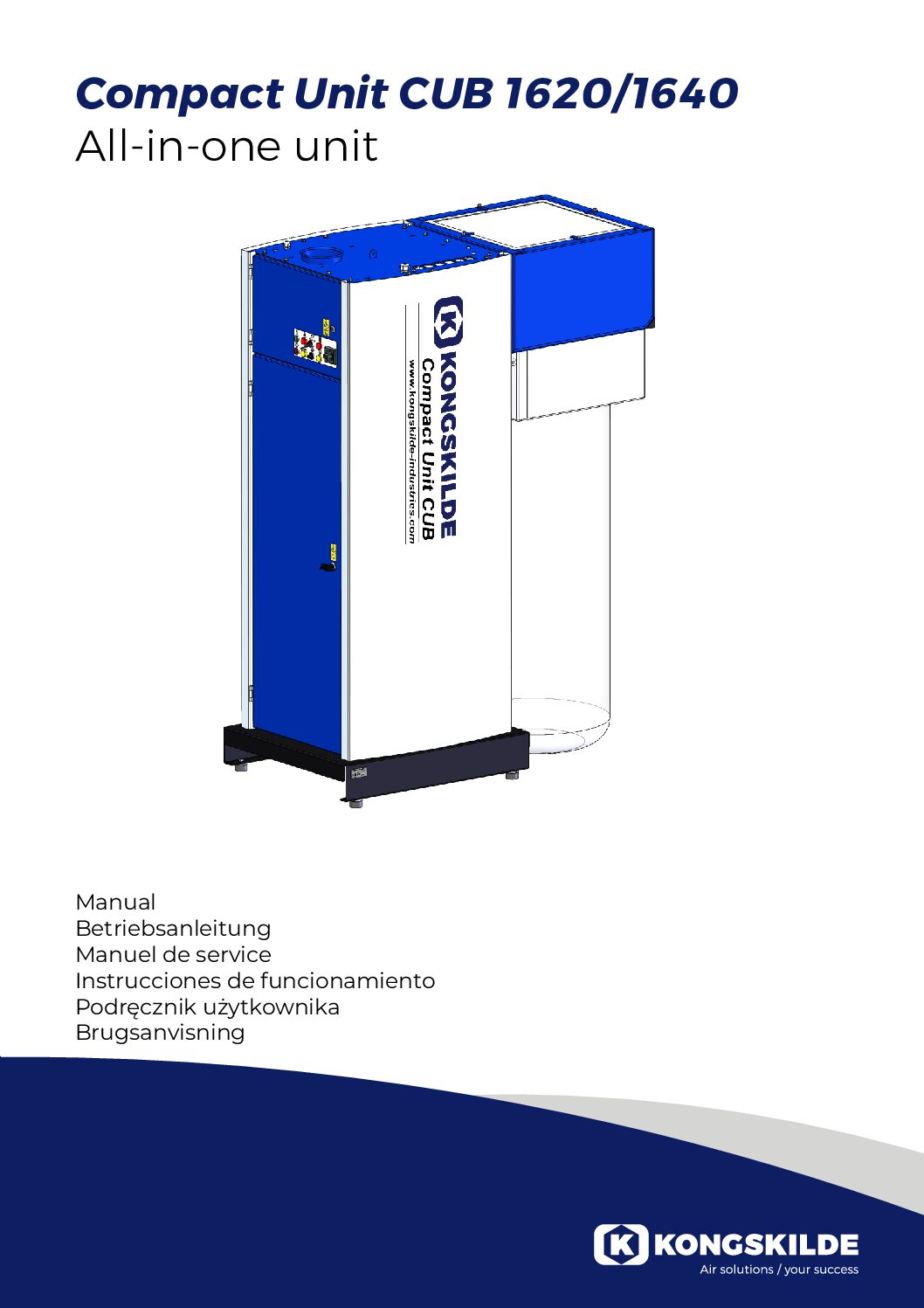

All-in-one Units

CUB – Compact Unit with Bag

A compact machine-side waste collection unit for process waste

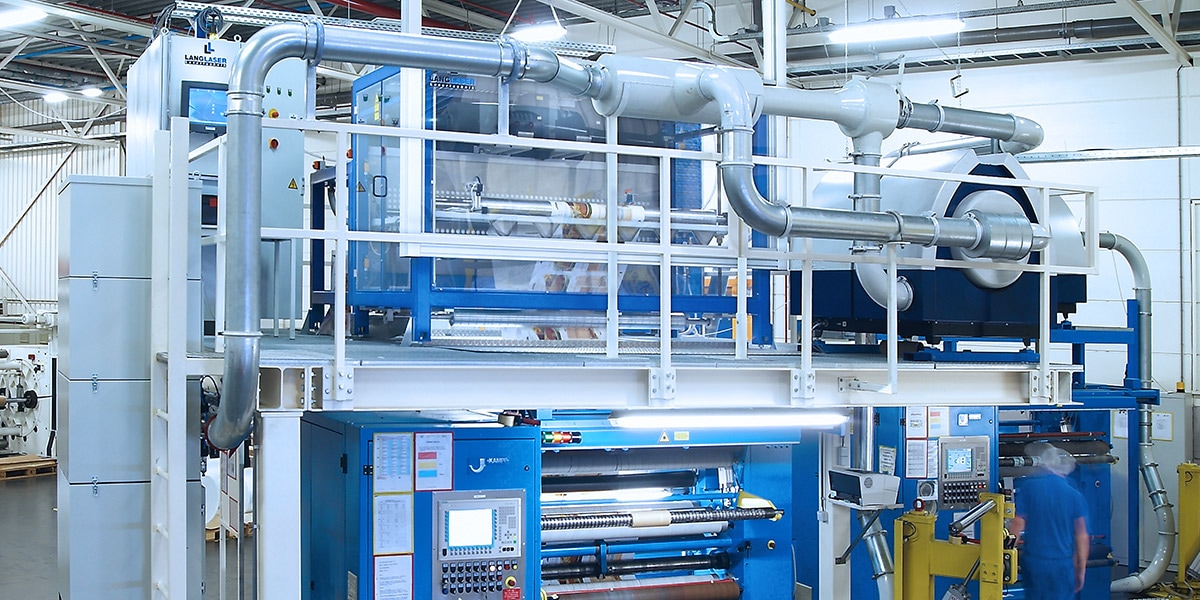

Optimize your manufacturing processes with our cutting-edge unit designed to handle both non-adhesive and self-adhesive edge trims, die-cut pieces, and matrix from one production line. Extremely compact and robustly manufactured, it can be moved easily between machines.

Additionally, the system can be customized with an integrated material separation system for recycling processes when needed.

Versatile Waste Handling

Tailored for production lines engaged in label converting, film extrusion, coating & lamination, slitting & rewinding, printing, or packaging production, this unit ensures seamless and efficient operations.

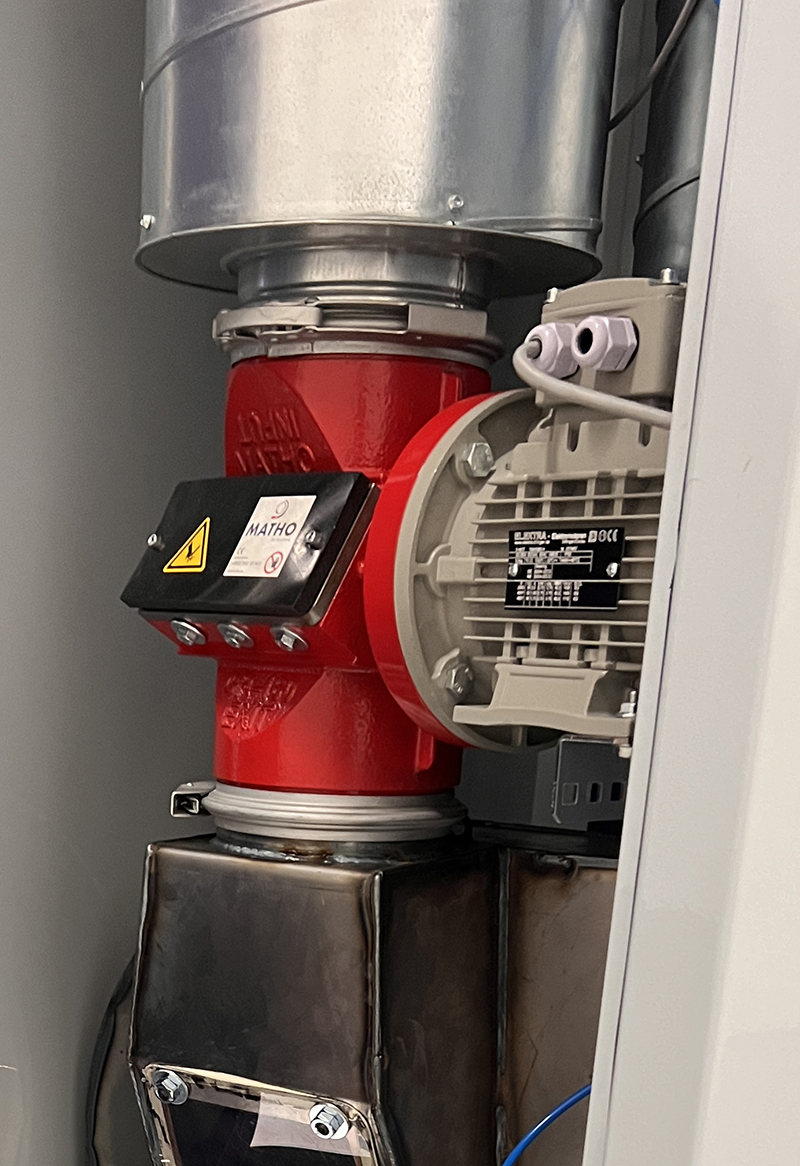

The Kongskilde CUB-1600 is a versatile and compact unit designed for handling various types of waste from machines. With a robust build, it can easily move between machines, transporting trim up to 35m and disposing it into a 900-litre bag. The unit comes in 2 models (2 kW or 4 kW) and 3 standard versions each, including basic, antistatic, or matrix options.

The CUB is available in 2 models and 3 standard versions of each model; 2kW or 4kW model, and a basic, antistatic, or matrix version. The antistatic model is ideal for static materials, while the matrix unit is designed for labels or sticky materials. Controls are simple and intuitive with push buttons and a speed dial, and the unit operates quietly within production environments.

Key Features

- Handles various types of waste, including static and sticky materials

- Simple controls with push buttons and speed dial

- Compact design with easy mobility

- Silent operation with big silencers

- F7 filter with an option to add a HEPA filter

- 900-litre bag for extended operation time

- Accessories available, including oil mist system, antistatic kit, HEPA filtration kit, endless bag kit, and level sensor with light tower kit

Benefits

- Cost-effective cutting and extraction system

- High availability and uptime

- Reduced waste volume with an integrated cutting module

- Low energy consumption with an energy-efficient radial ventilator

- Low maintenance costs

- Compact design with a minimal footprint

- Mobile and moveable system

- Low noise emission with modern pipe silencers

User-Friendly Controls

No complex PLC or HMI – just straightforward push buttons and a speed dial. Operate with ease and precision, enhancing your workflow without unnecessary complications.

Silent Operation

With its innovative design incorporating big silencers within a sealed steel enclosure, the CUB ensures silent operation, making it suitable for placement within the production environment without causing disruption.

Flexible Mobility

The CUB’s sleek design allows easy movement with a forklift or pallet jack, effortlessly passing through most factory doors. Adapt to your space with a width of just 800mm and a height of 2150mm.

Extended Operation

With a 900-liter bag capacity, enjoy longer operation times between bag changes. Need continuous operation? Our endless bag kit, easily closed with zip ties, keeps your workflow seamless.

Downloads

Download available brochures and data sheets.

CUB Model Comparison

Compare available Compact Unit – Bag models. Visit the downloads section for more information on specific models.

| CUB-1620 | CUB-1640 | |

|---|---|---|

| Material thickness | 20 – 300 μm | 20 – 300 μm |

| Blower Motor | 2.2 kW | 4.0 kW |

| Cutter Motor | 0.75 kW / 1,500 RPM | 0.75 kW / 1,500 RPM |

| Height x Width x Length | 2,150 x 800 x 1,570 mm | 2,150 x 800 x 1,570 mm |

Compact Unit Videos

Learn more about the Kongskilde Compact Unit and see it in action.