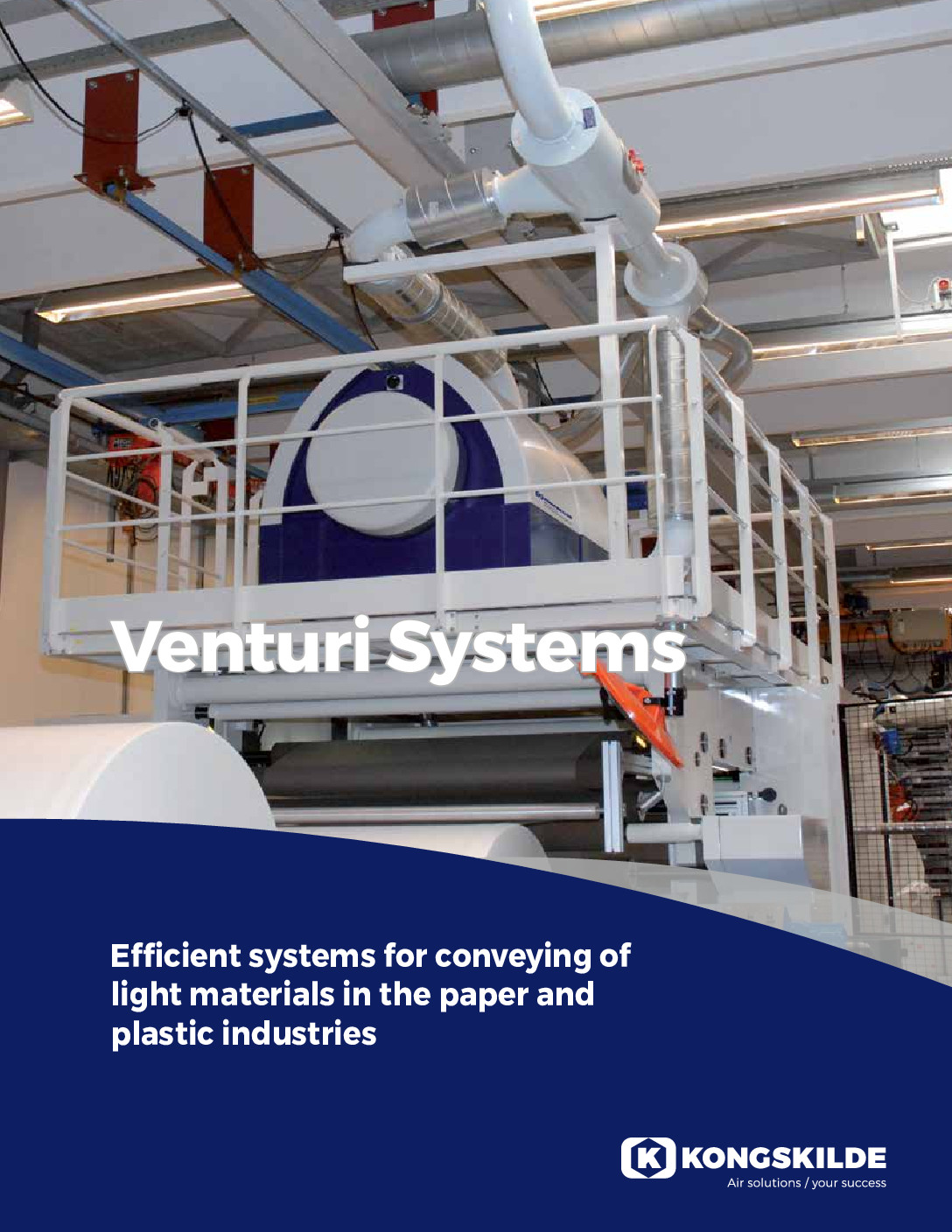

When it comes to moving blow molded bottles and products, an Inline Venturi system provides the ideal solution.

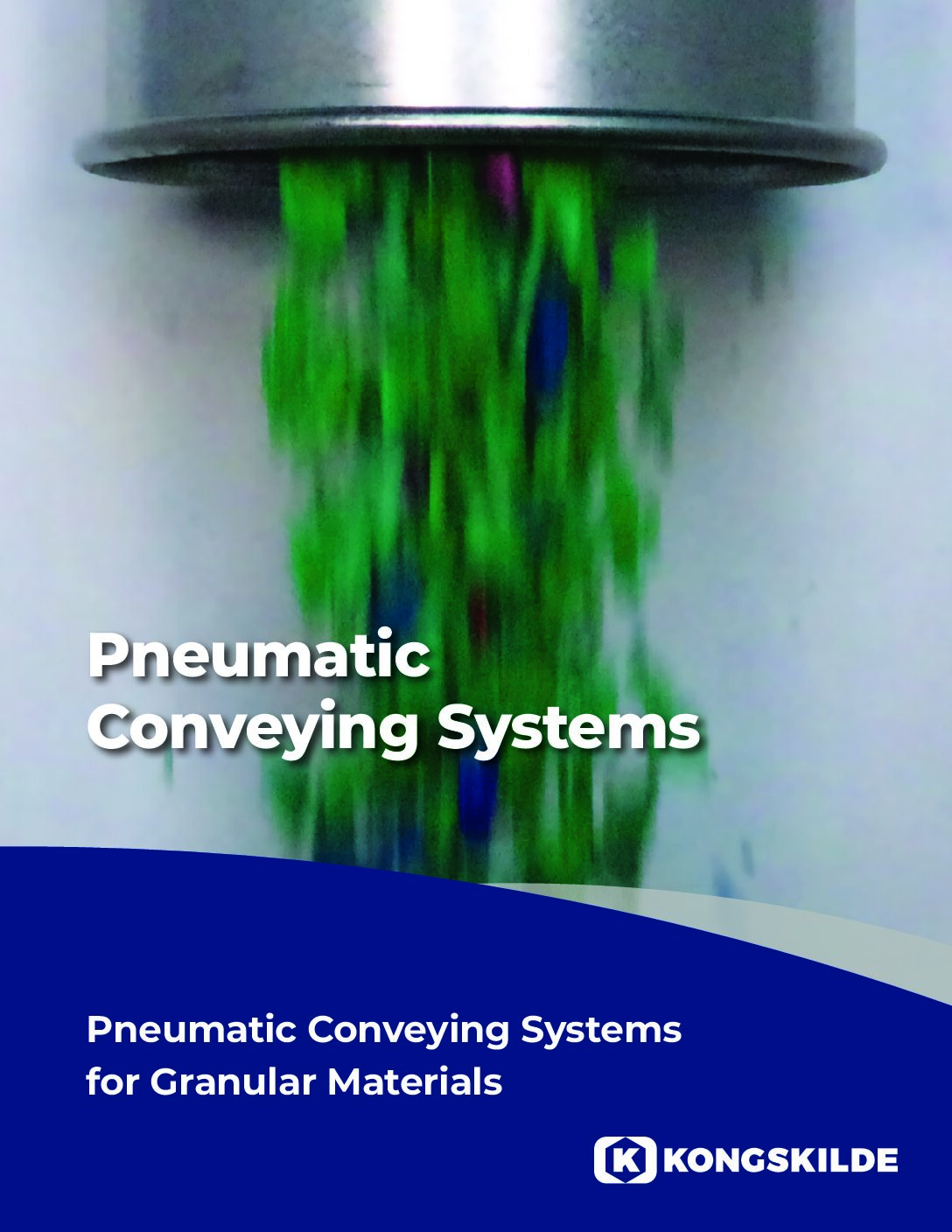

The future of conveyance takes advantage of one our most abundant natural resources: air. By utilizing pneumatic conveyance for blow molded plastics and other materials, smart operators can reclaim floor space, send materials longer distances, control contaminants, and reduce overall maintenance.

Most blow molded items can easily be transferred by a Inline Venturi (KIV) pneumatic conveyor system. From brand-new bottles to waste separation, has a variety of field-proven products and customizable solutions for nearly every application.

Solutions for Conveying of Blow Moulded Products

By utilizing pneumatic conveyance for blow-molded plastics and other materials, smart operators can reclaim floor space, send materials longer distances, control contaminants, and reduce overall maintenance.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Reduction of Dust and Fumes in Blow Moulded Plastic Bottle Production – Netherlands

A Dutch blow moulding producer needed a solution for reducing dust, angel hair, and peroxide fumes on their production sites.