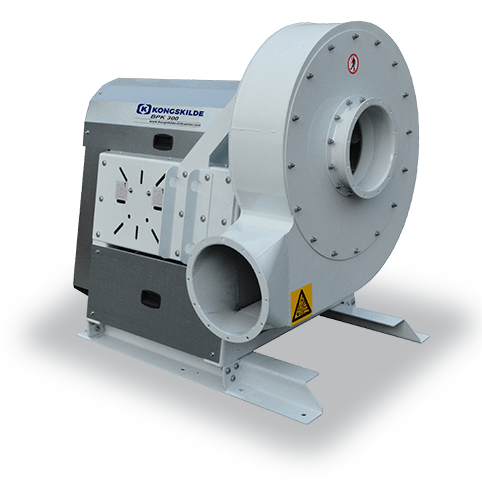

Conveying Blowers

Kongskilde conveying blowers are engineered to deliver high-performance pneumatic conveying for a variety of industrial applications. These air blowers are designed to efficiently transport materials through pipelines, providing a reliable and energy-efficient solution for handling bulk materials.

Understanding Pneumatic Conveying

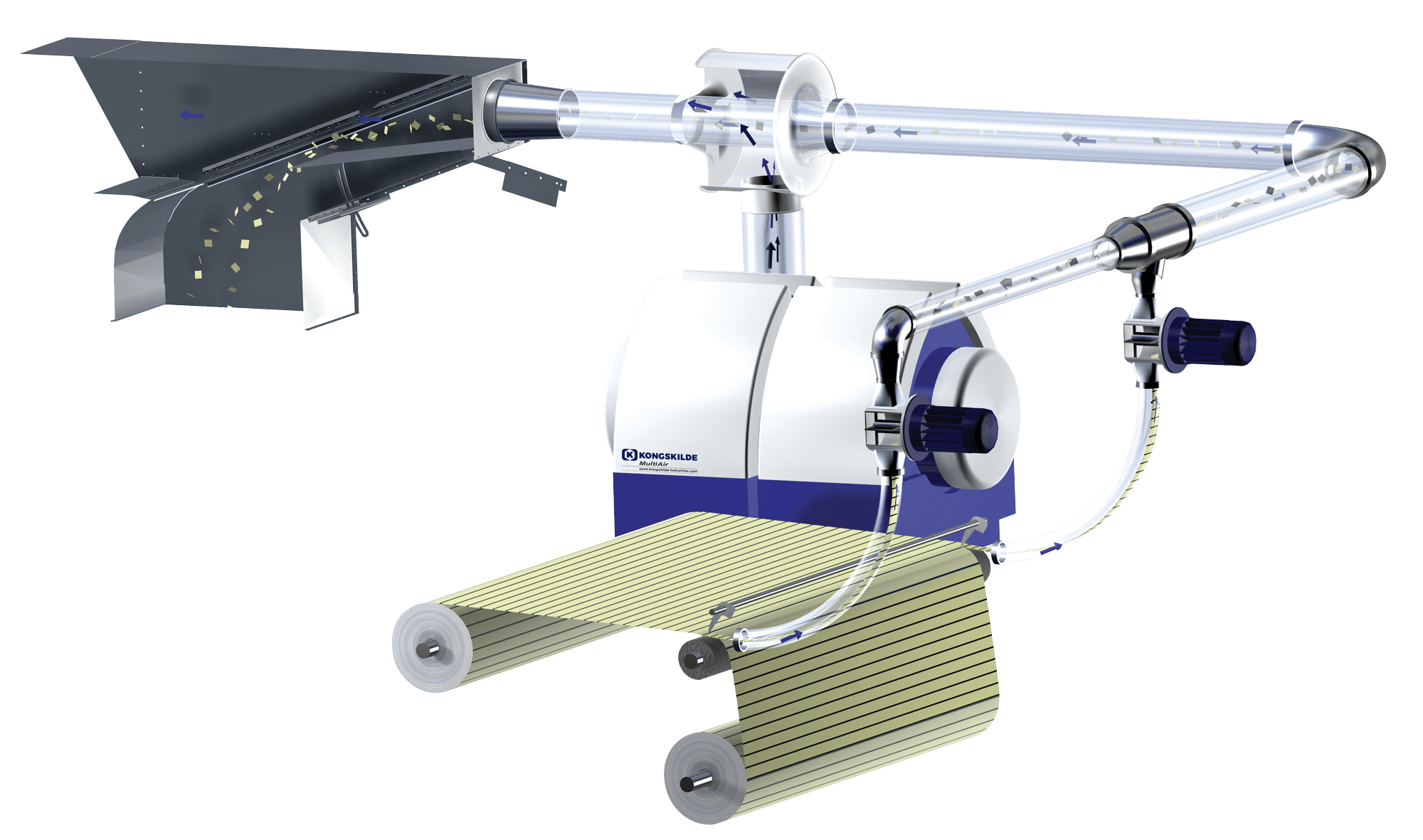

Kongskilde conveying blowers work by generating a powerful air stream that propels materials through conveying ducts or pipes. The system uses either positive or negative pressure to move materials such as granules, pellets, or off-cuts, from one location to another, ensuring a continuous flow that is both fast and secure.

Benefits of Kongskilde Conveying Blowers

Explore the distinct advantages that Kongskilde conveying blowers offer to streamline and enhance your material handling processes:

- High Efficiency: Optimizes power usage while maintaining high throughput, reducing operational costs.

- Versatility: Capable of handling a wide range of materials and suitable for various industrial settings.

- Low Maintenance: Designed for durability and long service life with minimal maintenance requirements.

- Improved Safety: Reduces the risk of material spillage and enhances workplace safety by containing materials within a closed system.

High-Pressure Blowers in Bulk Material Handling Systems

Bulk material handling involves using a range of equipment—manual, semi-automated, and automated—to manage the storage, control, and protection of conveyed materials. These systems focus on handling dry materials like plastic granulates and recycled flakes, crucial in various industries. Conveyor systems comprise diverse equipment types, including pneumatic conveying equipment, which manufacturers use to create cost-effective solutions. Industrial blowers, particularly high-pressure blowers, serve as essential air movement devices in these systems. At Kongskilde Industries, we provide reliable and efficient high-pressure blower solutions for your material handling needs.

FAQ: Conveying Blowers

What makes Kongskilde conveying blowers suitable for different industrial applications?

Kongskilde conveying blowers are designed with versatility in mind, able to handle various materials including plastics, granules, and other bulk materials. Their robust design and adjustable settings allow them to be customized to specific conveying needs, making them ideal for a wide range of industrial environments.

How do Kongskilde conveying blowers contribute to environmental safety?

By using pneumatic systems that enclose materials during transport, Kongskilde conveying blowers prevent dust and debris from escaping into the workplace. This not only improves air quality but also contributes to a cleaner and safer environment.

Can Kongskilde conveying blowers be integrated with existing production lines?

Yes, Kongskilde conveying blowers can be easily integrated into existing production setups. They are designed to complement other systems and can be configured to meet specific layout requirements, ensuring seamless operation and continuity in material handling processes.

Where are industrial blowers placed in material handling systems?

Industrial blowers can be implemented at the beginning of the bulk material handling equipment line to deliver overpressure or at the end of the line to generate a vacuum. Additionally, blowers serve in cleaning and exhaust processes.

How do industrial blowers optimize airflow?

Industrial blowers use centrifugal fans with forward or backward-curved blades to increase the pressure of incoming airstreams. These fans use impellers to accelerate air radially and alter the direction of outward-flowing air, optimizing airflow for material handling.

What should I consider when selecting an industrial blower?

Selecting the right industrial blower is crucial for material handling conveyor equipment. Errors can influence material flow rate and may necessitate changes to system sizing and design. Incorrect equipment selection can cause blockages where active airflow is lowest. Kongskilde Industries assists in considering all these factors and more to ensure the right decision is made.

What are the key factors to understand in conveyor systems?

Awareness of pressure levels and the required flow rate is essential for moving material through bulk material handling equipment. These factors impact the conveyor system’s reliability. Relevant information includes pipe sizing, distance, and material weight.

How do forward and backward curved fans compare in industrial settings?

Forward curved fans are ideal for low-speed and low-pressure applications. Backward curved fans generate medium to high airflow and achieve the highest operating speeds. Designers tailor various centrifugal fan models to specific industrial needs, considering airflow, pressure, volume, and efficiency. Many of our models come equipped with self-cleaning rotors.

Kongskilde Industries’ Approach to Tailored Conveying Solutions and Blower Selection

Kongskilde Industries designs effective conveying equipment, including blowers for clean air transport, ventilation, and material handling with centrifugal units. Recognizing that specific products excel in particular situations simplifies the selection process. This makes it logical and stress-free, a process we eagerly support and guide.

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.