Suction Blowing Systems

SUC Suction Blowing Systems

High-performance suction blower for the conveying of granulates

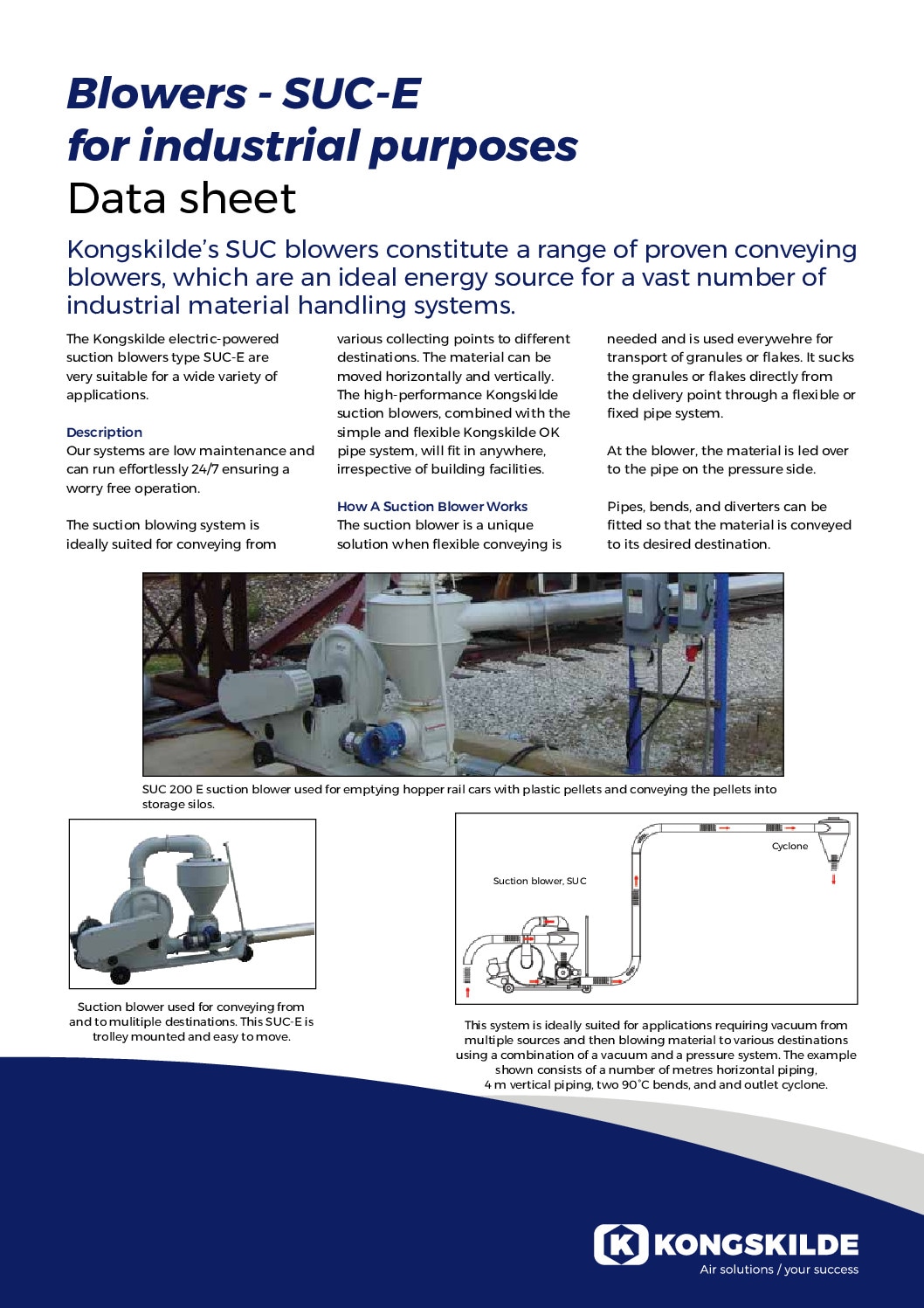

The electrically powered Kongskilde suction blowers SUC offer one of the most versatile conveying systems on the market for free flowing types of granulate.

Materials can be moved – horizontally and vertically – from various collecting points to different destinations, as required by the user. It is only necessary to place the suction head in the material – the suction blower will do the rest.

Flexible conveying system for pneumatic granulate transport

Kongskilde Industries offers a range of proven conveying blowers. SUC blowers are an optimal source of energy for a multitude of industrial granules material handling systems.

A conveying system moves materials from point A to point(s) B. A suction blower is a dedicated machine used for pneumatic granulate transport. In simple terms, this means that they operate via vacuum and air pressure in order to move substances such as granules from their original collection point to the preferred destination.

Applications

In order to accomplish their task as efficiently and practically as possible, a suction blower needs both a high suction and blowing power. The use of industrial suction blowers is versatile, however, they are most often used in the transport of granules from a place of storage (e.g. a silo) to a truck or other types of day tanks.

These systems are used in a multitude of industries and are often necessary for production, product transfer, and/or recycling processes.

How it works

The transport of granules is accomplished by extraordinarily high suction capacity.

Suction capacity is defined as the negative pressure produced when using a particular machine. In order to obtain this high suction capacity, suction blowers convert the kinetic energy of a rotating wheel to air, thereby transforming the circular motion into pressure and thus a space void of matter – also referred to as a vacuum.

The creation of a vacuum, therefore, occurs as a result of air being removed in order to force substances into a space devoid of matter via diffusion.

- Conveying begins when the suction air of the blower is used to lift and accelerate the granulate.

- Next, before the granulate arrives at the blower housing, separation from the air stream in a cyclone occurs and the granulate is dropped into the rotary valve.

- The rotary valve, in turn, conveys the granulate to the pressure side of the transport pipe from the suction side.

- Finally, the granulate is transferred by pressure to the outlet cyclone.

Highlights

- These suction-blowing systems can run 24/7 and are relatively low maintenance.

- Materials can be moved both horizontally and vertically, which makes the systems highly adaptable – an often overlooked, yet necessary feature.

- The suction blower itself can be delivered with an adjustable air intake nozzle so that a balance between air and material can exist.

- Kongskilde Industries’ systems can be modeled to suit the industrial space available and intended granulate.

SUC Downloads

Download manuals, data sheets, and spare parts lists for the SUC Suction Blower.

Data Sheets and Manuals

Spare Parts

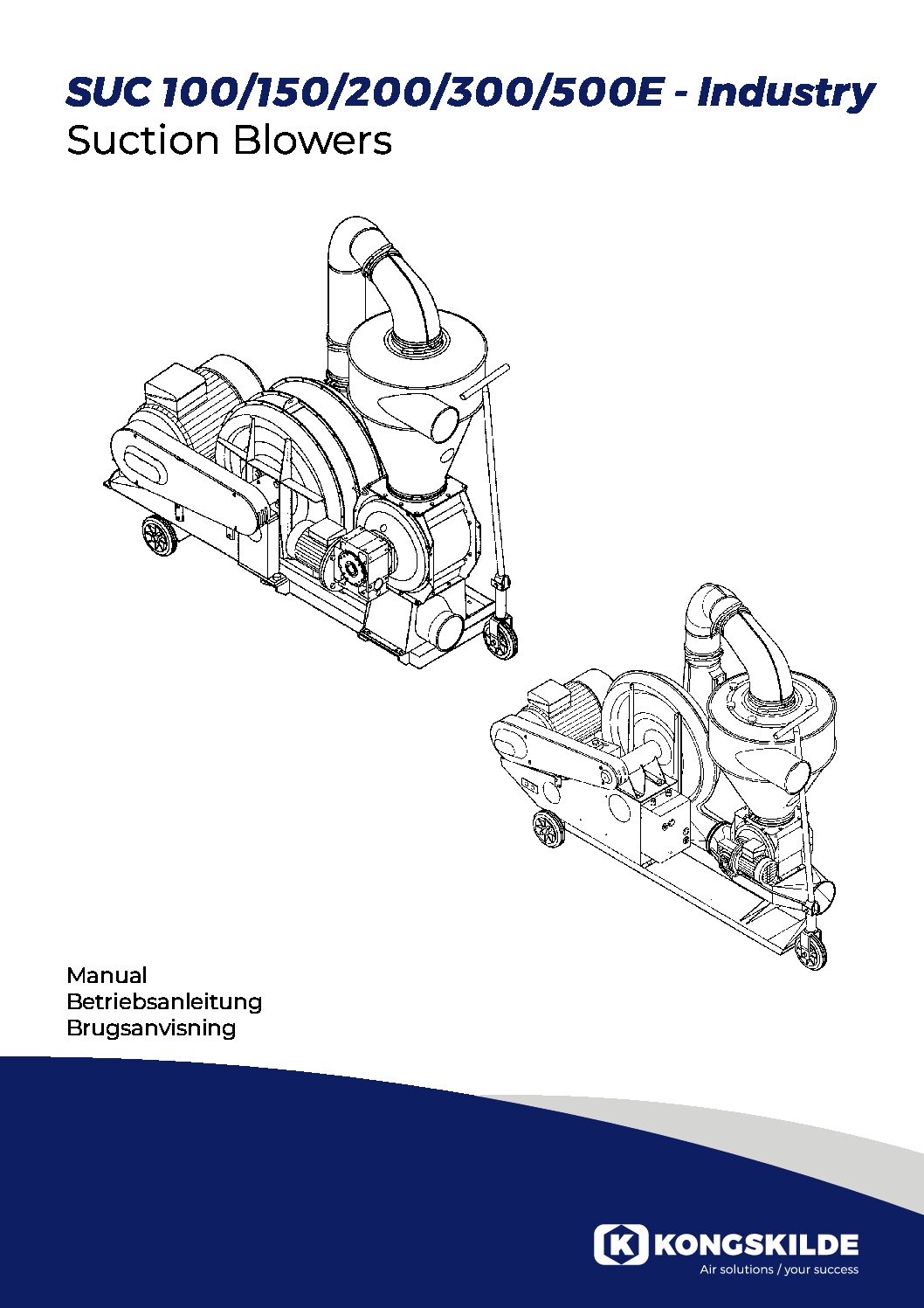

SUC Model Comparison

Compare available SUC models. Visit the downloads section for more information on specific models.

| SUC 100 E | SUC 150 E | SUC 200 E | SUC 300 E | SUC 500 E | |

|---|---|---|---|---|---|

| Motor (blower) kW (HP) | 7.5 (10) | 11 (15) | 15 (20) | 22 (30) | 37 (50) |

| Motor (rotary valve) kW (HP) | 0.75 (1) | 0.75 (1) | 0.75 (1) | 1.1 (1.5) | 1.5 (2) |

| Total amp. consumption | 18.3 | 26.6 | 33.1 | 49.6 | 78.6 |

| Rotor, rpm (blower) | 3650 | 4200 | 4700 | 3450 | 4300 |

Related Products

The suction blowers, combined with a flexible OK pipe system, can be fitted into virtually any production area irrespective of facilities. Suction blowers suck granules or flakes directly from a suction point, and the bends and pipe diverters are fitted so that materials are conveyed to desired delivery point as efficiently as possible.

SUC Suction Blowing System Applications

SUC suction blowing systems are used in many different industries for production, product transfer, and/or recycling processes.