The Challenge

This Dutch global company produces both custom and standard blow moulded plastic bottles and containers.

The factory is located next to its largest customer sharing the same building, only separated by a wall. The pickup points for rejected material are located on the customer’s side of the wall.

The issue is the presence of dust, angel hair, and Peroxide fumes from the customer’s production site as well as dust and angel hair from their own production site (Peroxide is used for cleaning in the production area of their customer).

The Peroxide fumes were going through the suction points of the conveying system into the cyclones. Since the outlet of the cyclones were not connected to the outside or a filter, the air, dust and fumes were released inside the waste handling room. The Kongskilde solution is designed to eliminate the dust and fumes issue.

The Solution

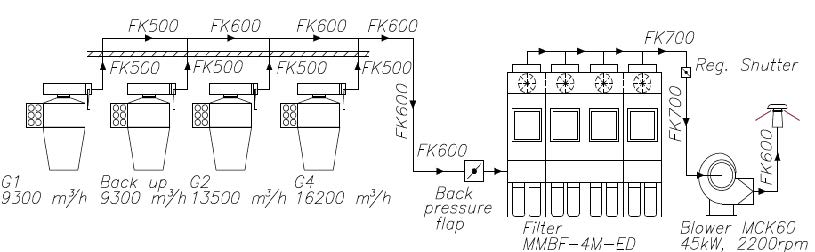

- With Kongskilde’s wide product range, a solution with cyclones, pipelines, and top outlet boxes were made to convey the dust and Peroxide fumes, despite very limited space in the production hall

- The solution consists of an MMBF-4M filter with Rotary valve to clean the air, MCK 60 blower with an external frequency controller in a sound booth to extract the air from all the cyclones. The FK 500 and FK 600 pipes were able to handle the high pressure even when routing was 90 meter

The Advantages and Benefits

- The flexible pneumatic solution has a considerable positive effect on the health and safety working environment with the dust and fume issues under control. A cleaner space area without dust and fumes brings better working conditions and less risk of work-related diseases.

- Less need for maintenance of the pneumatic conveyor solution and even less need for cleaning the factory without the dust issues gives a net cost saving.

- High flexibility and modularity means a quick setup of the pneumatic conveyor solution even to meet special requirements. And with the pipes mounted on the ceiling, it releases floor space for other uses.

The Facts

- Material: Dust. HDPE, PP and PET

- Demands from customer. 24.000m3/hr. (divided over 4 cyclones)

- Suction points: from 4 cyclones to filter.

- Bulk density: Dust and fumes

- Conveying distance: H: max 90 mtr. V: max 7 mtr