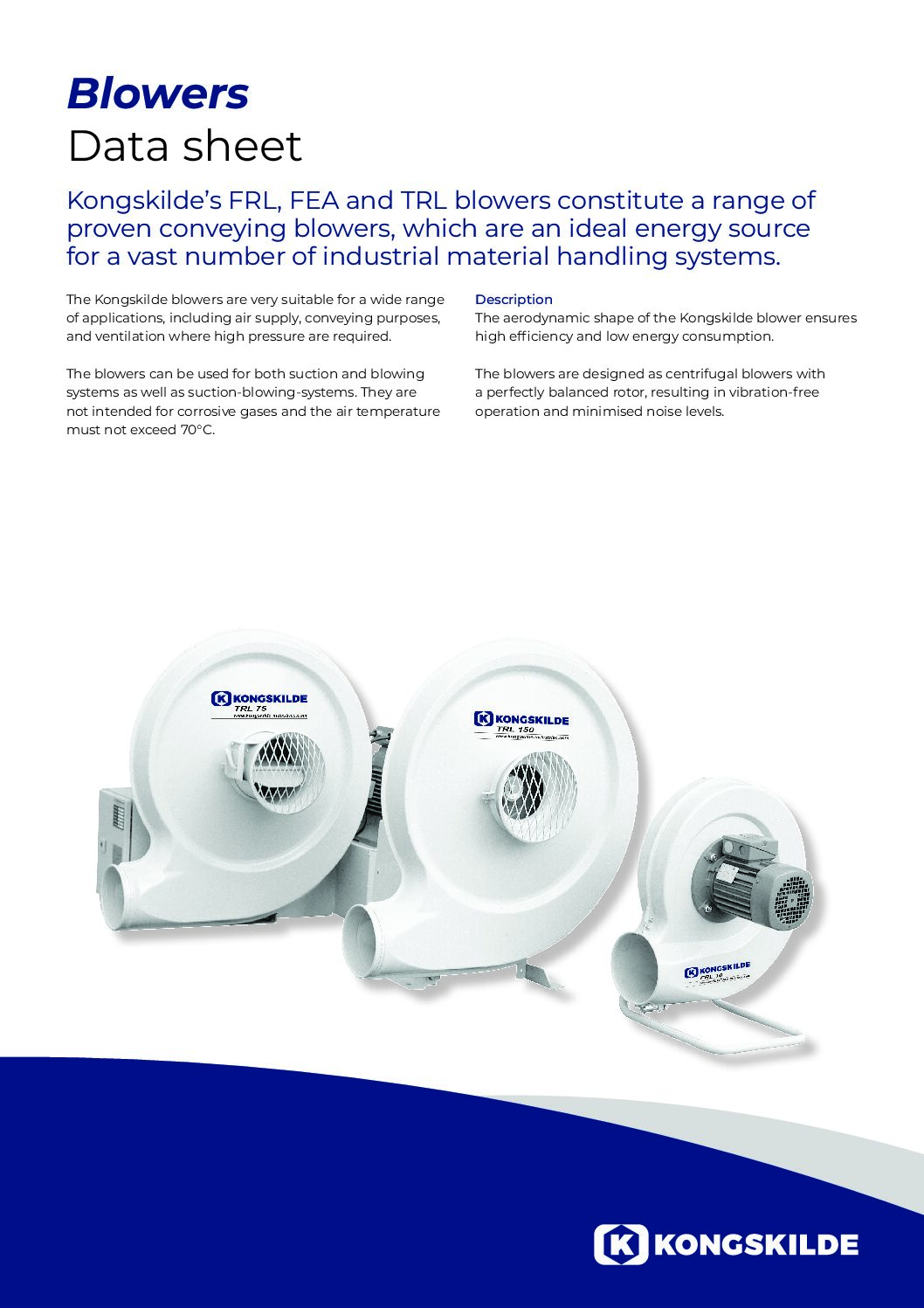

Conveying Blowers

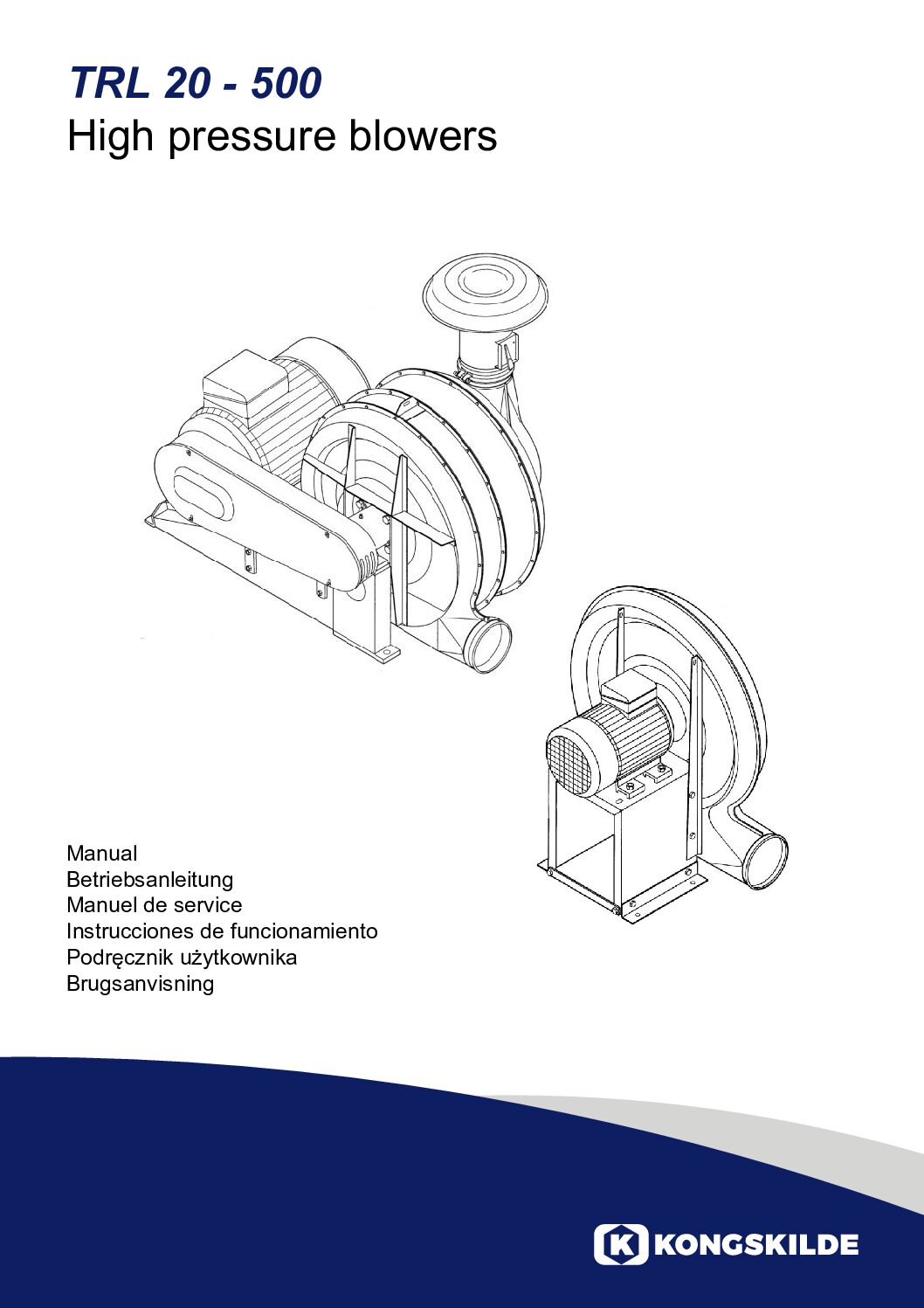

TRL Blowers

High-pressure blower suitable for both suction and blowing systems, as well as suction-blowing systems

Kongskilde’s TRL series of high-pressure blowers are engineered to deliver superior performance in demanding industrial environments. Whether you need to convey granular materials or manage ventilation tasks, these blowers offer the robustness and efficiency your operations require.

How Kongskilde’s High-Pressure Blowers Work

The TRL high-pressure blowers are designed as centrifugal fans that feature perfectly balanced rotors for vibration-free, quiet operation. They effectively create high air pressure, which is crucial for efficient material movement and air quality control in both suction and blowing systems.

TRL Air Regulator

Combining the blower with an air regulator optimizes the conveying airspeed, which minimizes damage to the material even when conveying delicate materials. The constant air velocity also prevents the overloading of the motor and minimizes the power consumption.

Benefits of Using Kongskilde High-Pressure Blowers

- Energy Efficiency: Aerodynamic design ensures minimal energy consumption while maintaining high efficiency.

- Versatile Applications: Suitable for a variety of tasks from material conveying to fume suction and general ventilation.

- Flexible Installation Options: Modular pipe components allow for easy and adaptable setups in diverse industrial spaces.

- Reliable Operation: Designed for minimal maintenance with a closed rotor system that prevents material pass-through and reduces wear.

Features

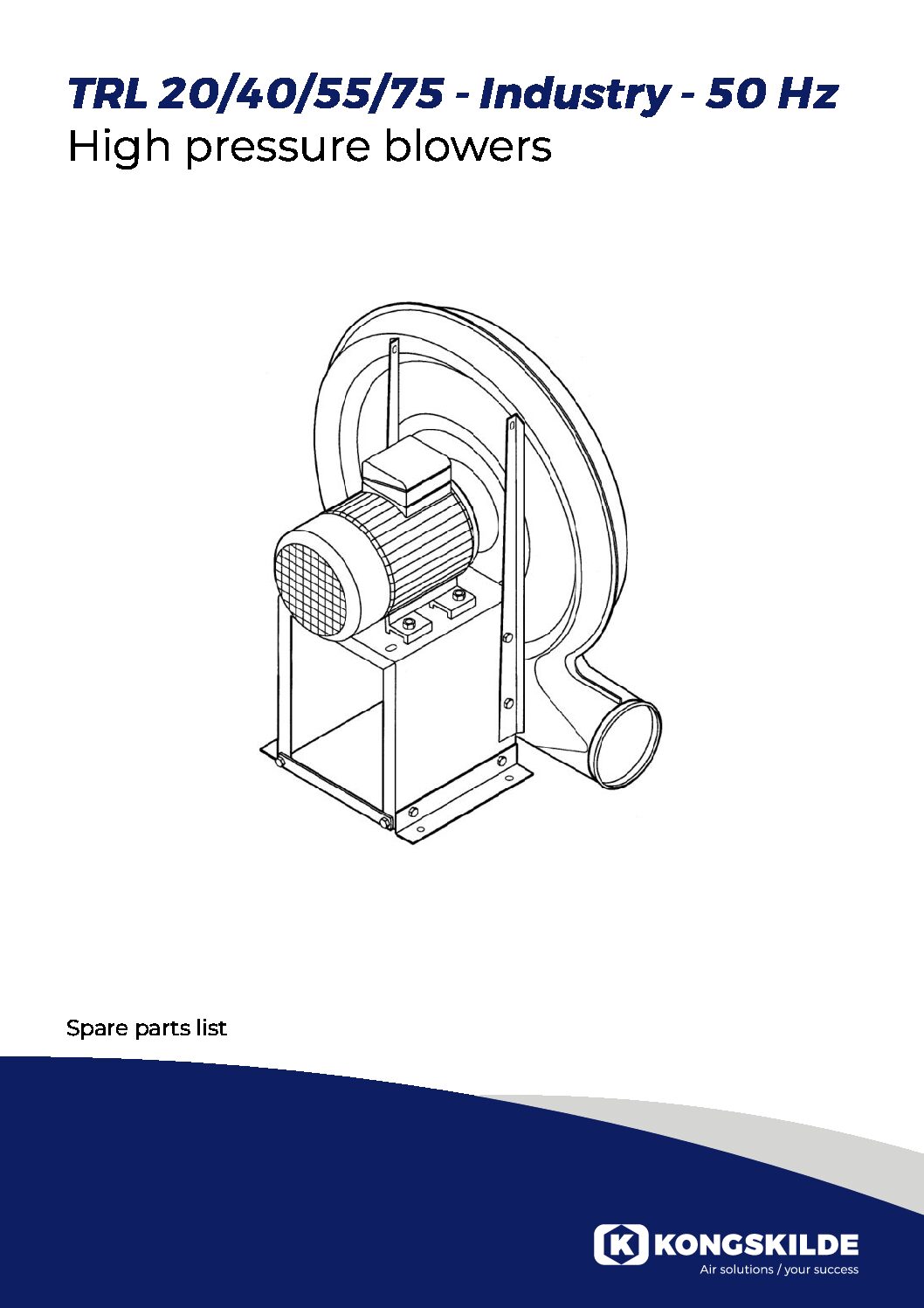

- The small and medium-sized blowers are one-stage centrifugal blowers with closed rotors, whereas TRL 300 and 500 have two respectively three stages, which also are equipped with, closed rotors.

- Select models are equipped with air regulators.

- Smaller models can be used as either a transport blower or suction blower.

- Many midsize and large models can be utilized for both suction and blowing systems, or as a combination of a suction-blowing system.

- The material does not pass through the blower.

Downloads

Download data sheets, manuals, and spare parts lists for TRL blowers. For wiring diagrams, please contact us.

Data Sheets and Manuals

Spare Parts

TRL Model Comparison

Compare available TRL blower models. Visit the downloads section for more information on specific models.

| TRL 20 | TRL 40 | TRL 55 | TRL 75 | TRL 100 | TRL 150 | |

|---|---|---|---|---|---|---|

| Blower rpm | 3000 | 3000 | 3000 | 3000 | 3650 | 4200 |

| Amp. consumption | 3.1 | 4.4 | 7.5 | 10.5 | 20 | 27 |

| Motor rating, kW (HP) | 1.5 (2) | 3 (4) | 4 (5.5) | 5.5 (7.5) | 7.5 (10) | 11 (15) |

| TRL 200 | TRL 300 | TRL 500 | TRL 600 | TRL 750 | TRL 1000 | |

|---|---|---|---|---|---|---|

| Blower rpm | 4700 | 4100 | 4300 | 3905 | 4310 | 4780 |

| Amp. consumption | 33 | 39 | 65 | 78 | 96 | 129 |

| Motor rating, kW (HP) | 15 (20) | 22 (30) | 37 (50) | 45 (60) | 55 (75) | 75 (100) |

TRL Blowers Applications

Kongskilde’s TRL blowers are ideal for a wide range of industries needing reliable high-pressure solutions. They are especially effective in settings that require the conveying of granular materials, extraction of welding fumes, and the implementation of robust ventilation systems.