Streamlined Conveying for Blow Molded Products

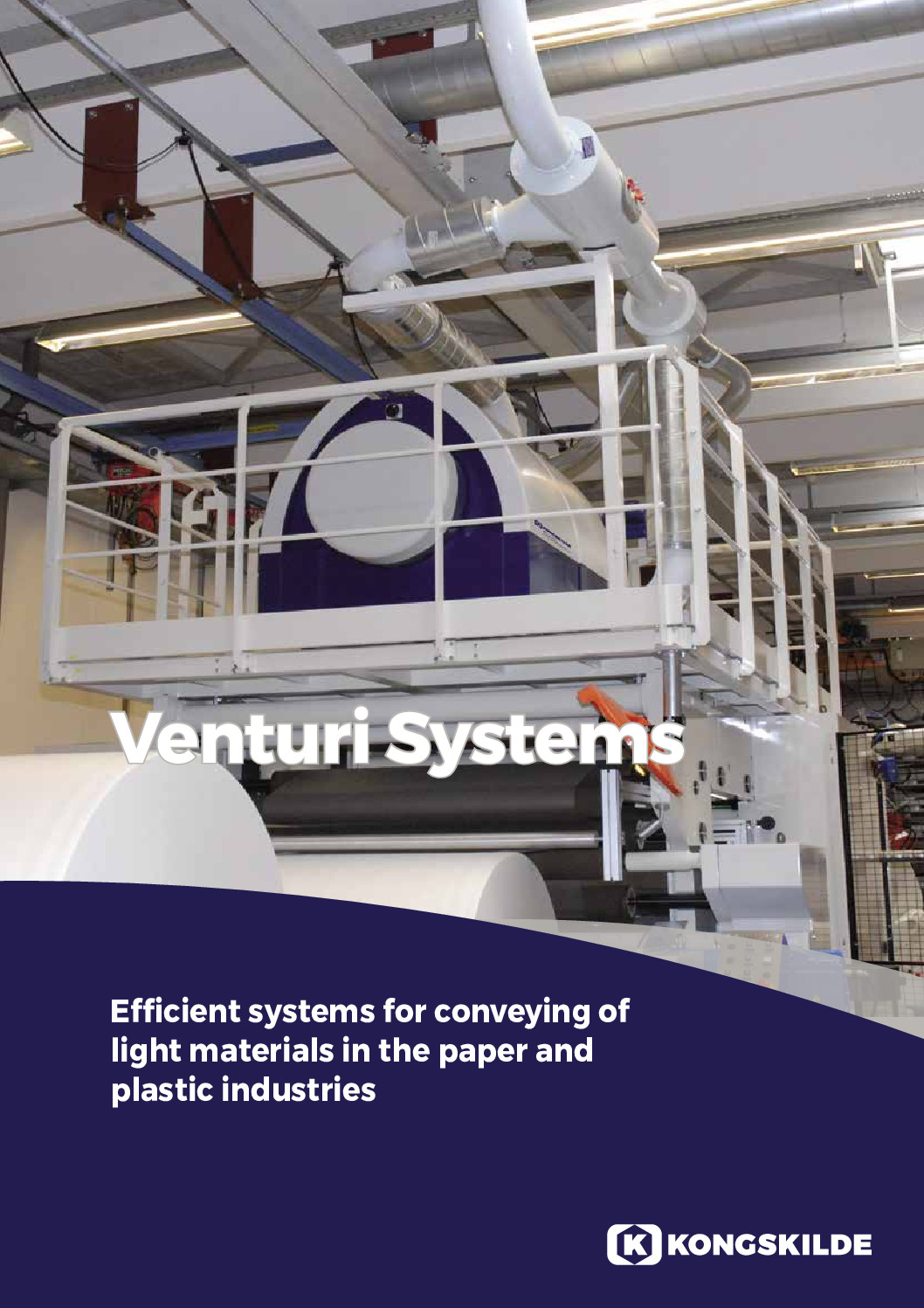

Kongskilde’s Inline Venturi systems provide an effective and energy-efficient solution for transporting blow molded parts using air. These pneumatic systems eliminate mechanical components from the conveying process, reducing maintenance while improving cleanliness and control.

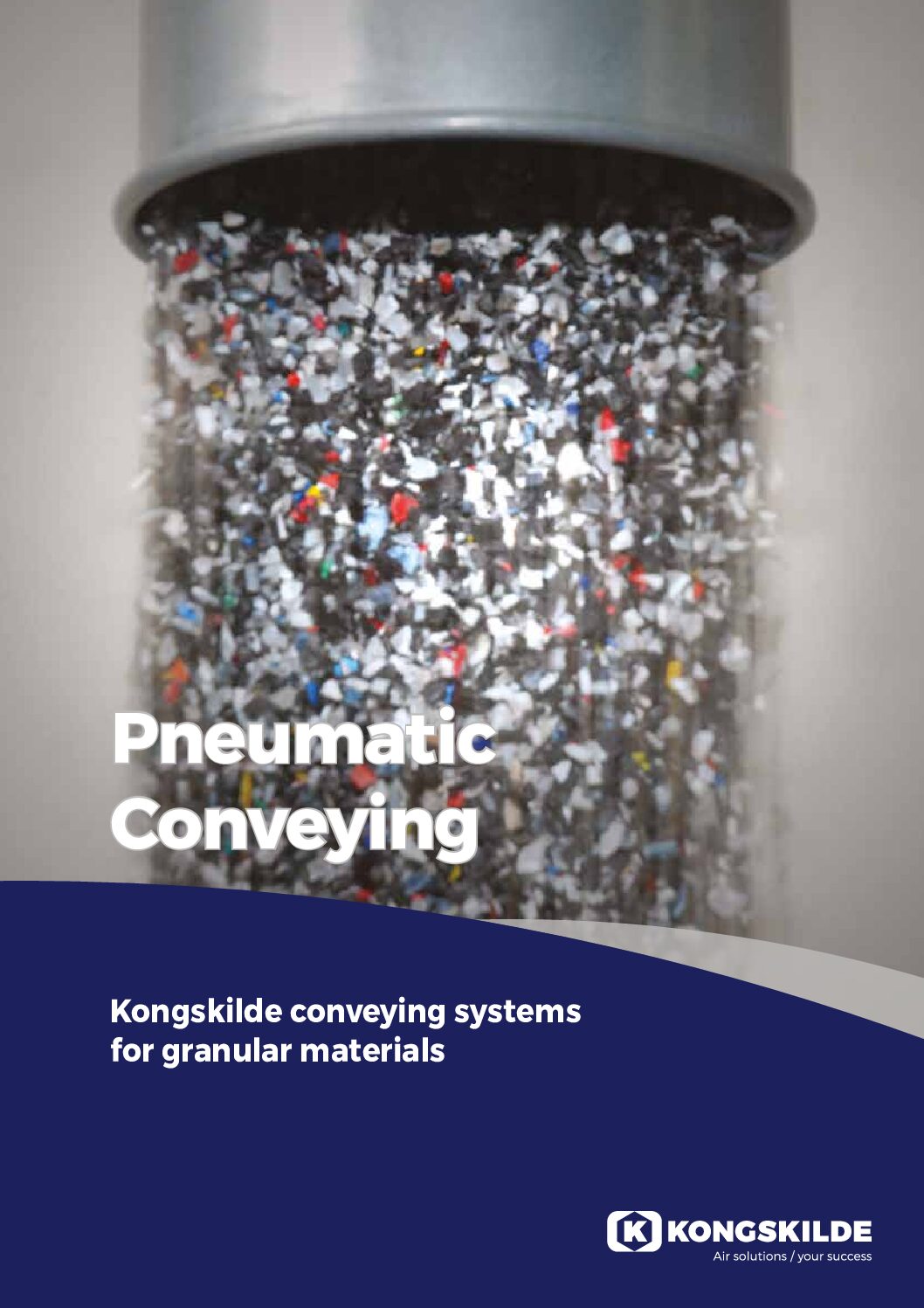

Whether you’re handling brand-new bottles or separating production waste, our pneumatic scrap conveying solutions are designed to reclaim floor space, extend conveying distances, and maintain product integrity—all with low operating noise and high reliability.

Solutions for Conveying of Blow Moulded Products

Operators across the plastics and packaging industries use Kongskilde systems to:

- Maximize layout flexibility and uptime

- Transport blow molded bottles from production to storage bins

- Convey parts from storage to packaging lines

- Implement internal recycling via pneumatic scrap conveying systems

- Minimize contamination during transport

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Cleaning of Regrind Plastic Material in the Automotive Industry – USA

An automotive manufacturer in the USA needed a solution to remove dust from the work environment and increase the use of regrind material.