Efficient Dust Removal for Plastic Processing

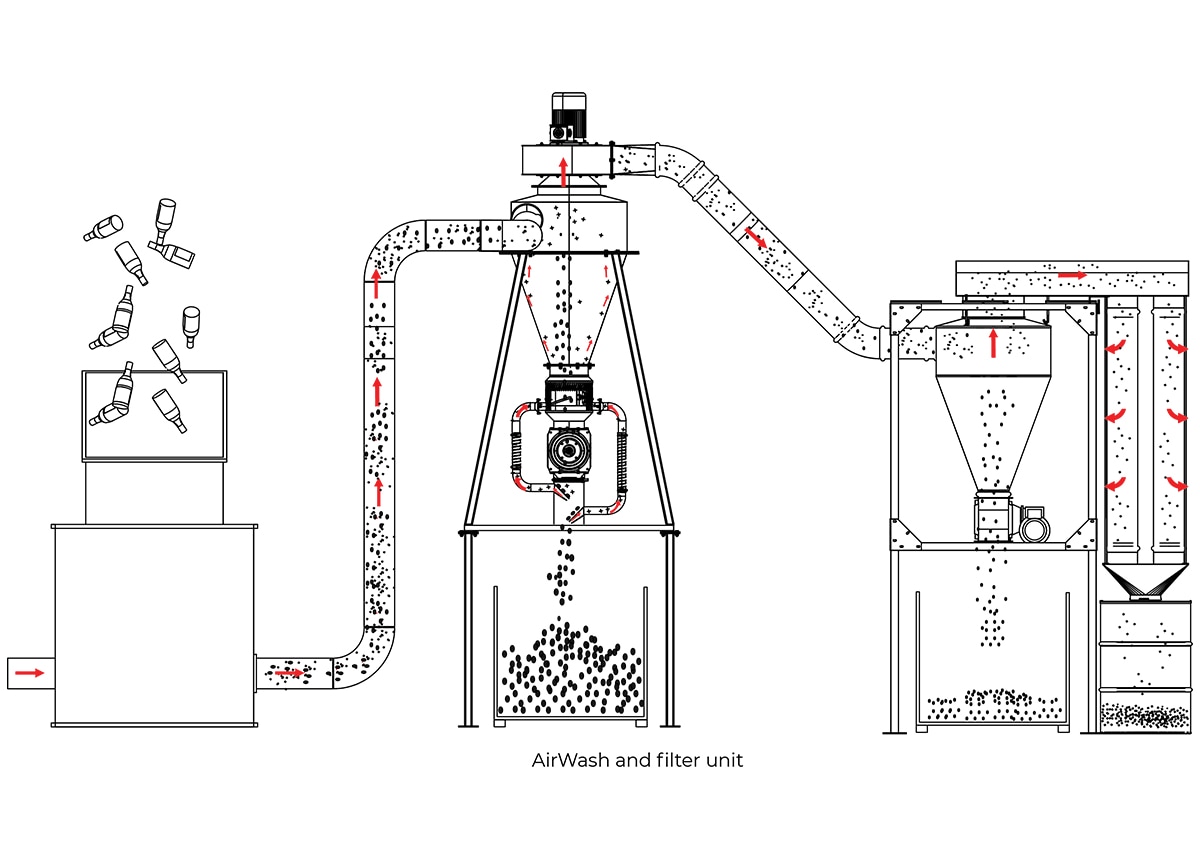

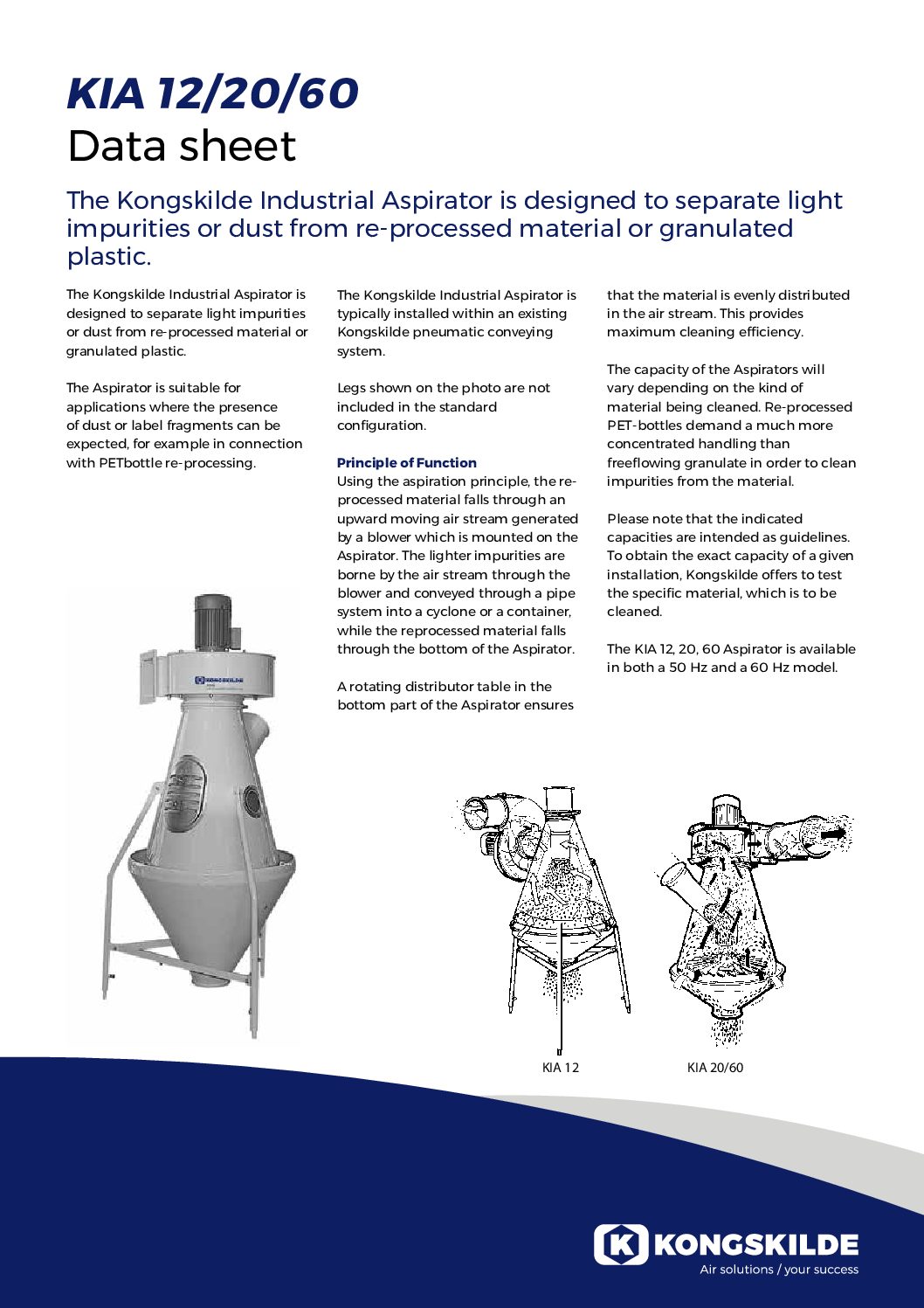

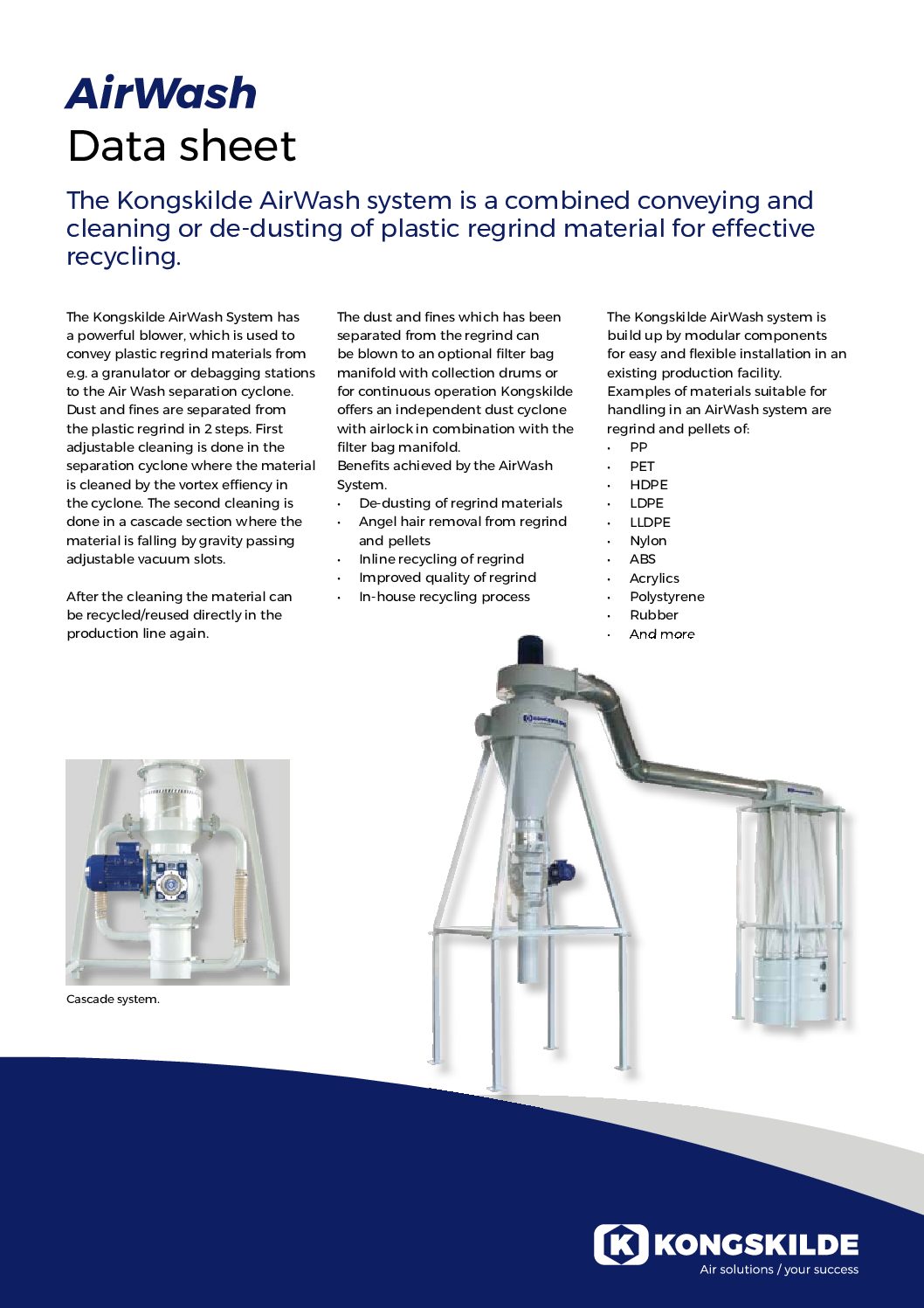

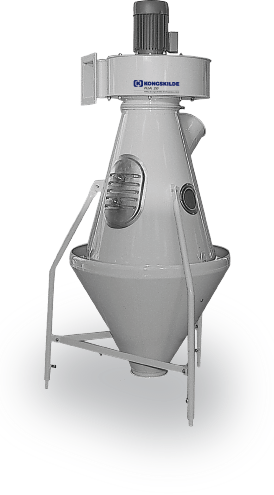

Dust and light impurities in plastic regrind or virgin pellets can compromise the quality of molded parts and contribute to equipment wear and environmental hazards. Kongskilde offers reliable dedusting solutions such as the patented AirWash system and our high-performance KIA Aspirator units to efficiently separate fine particles from re-processed materials.

Our plastic regrind dust collector options are designed to improve:

- Product quality by reducing contaminants

- Workplace safety by minimizing airborne dust

- Equipment longevity by preventing buildup

- Production efficiency by reducing downtime

These systems can be integrated directly into your conveying setup, offering a seamless and gentle way to clean plastic materials during processing or recycling.

What is Dedusting?

Dedusting is the process of separating fine dust and light impurities from granulates, plastic pellets, or flakes. Using airflow-based separators like aspirators, our systems remove unwanted particles from plastic regrind material before further processing. Clean pellets pass through the aspirator outlet, ready for reuse or molding.

This step is a critical part of quality control in plastic recycling and manufacturing workflows.

Kongskilde Dedusting Systems and Products

Aspirator solutions prove an efficient means of dedusting processed materials or granulated plastic.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Cleaning of Regrind Plastic Material in the Automotive Industry – USA

An automotive manufacturer in the USA needed a solution to remove dust from the work environment and increase the use of regrind material.