The Challenge

The customer had several challenges they needed to address in their production:

- Wanted 6 new individual Venturi systems to optimize efficiency from 6 extruders.

- Conserve floor space and discharge material at 2 opposite points of the factory where briquette machines were placed.

- Better air separation.

- A more efficient system with enhanced safety features.

- Completely mitigate stops and remove downtime.

The Facts

- Production:

- Consumption of new blower = €22,000/year saved

- Avoiding stops (0% Stop)= €40,000/year saved

- Eliminated Compressed air = €9,000€/year saved

- Hours of maintenance reduced = €9,000-€12,000/year

- Improved safety through reduction of noise pollution by about 10%

- Breakdown, corrective maintenance, and stops eradicated

- Conveying distance:

- 10 – 25m and 5 bends

- Trim thickness/Speed relation:

- 10 – 25 micron at 60-110 m/min

- 30 – 50 micron at 45-60 m/min

- 50 – 90 micron at 25-50 m/min

- 90 – 180 micron at 12-25 m/min

The Solution

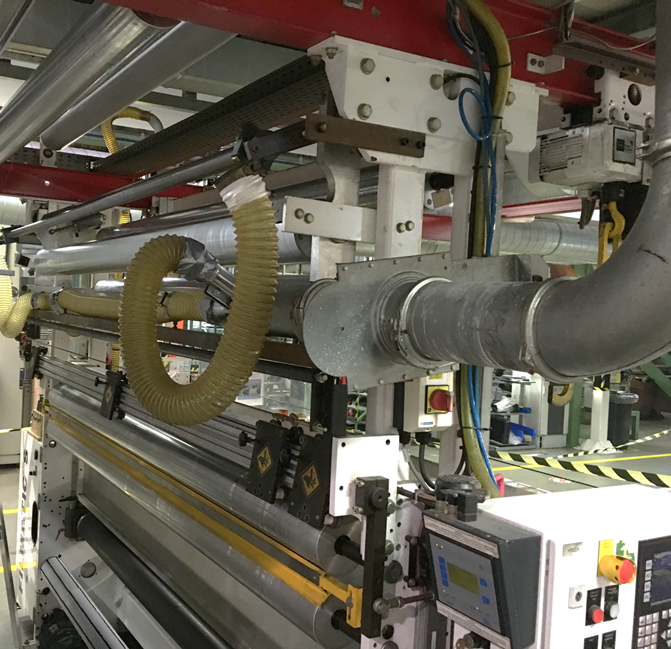

- Renew and optimize efficiency at 6 extruder machines.

- For each extruder, we installed 2xØ60 or 3xØ60mm pick-up points, each one ended by a steel flex hose of 1.2 meters.

- Both suction points joined into a common duct that will connect to an individual Venturi ITF 100 per machine.

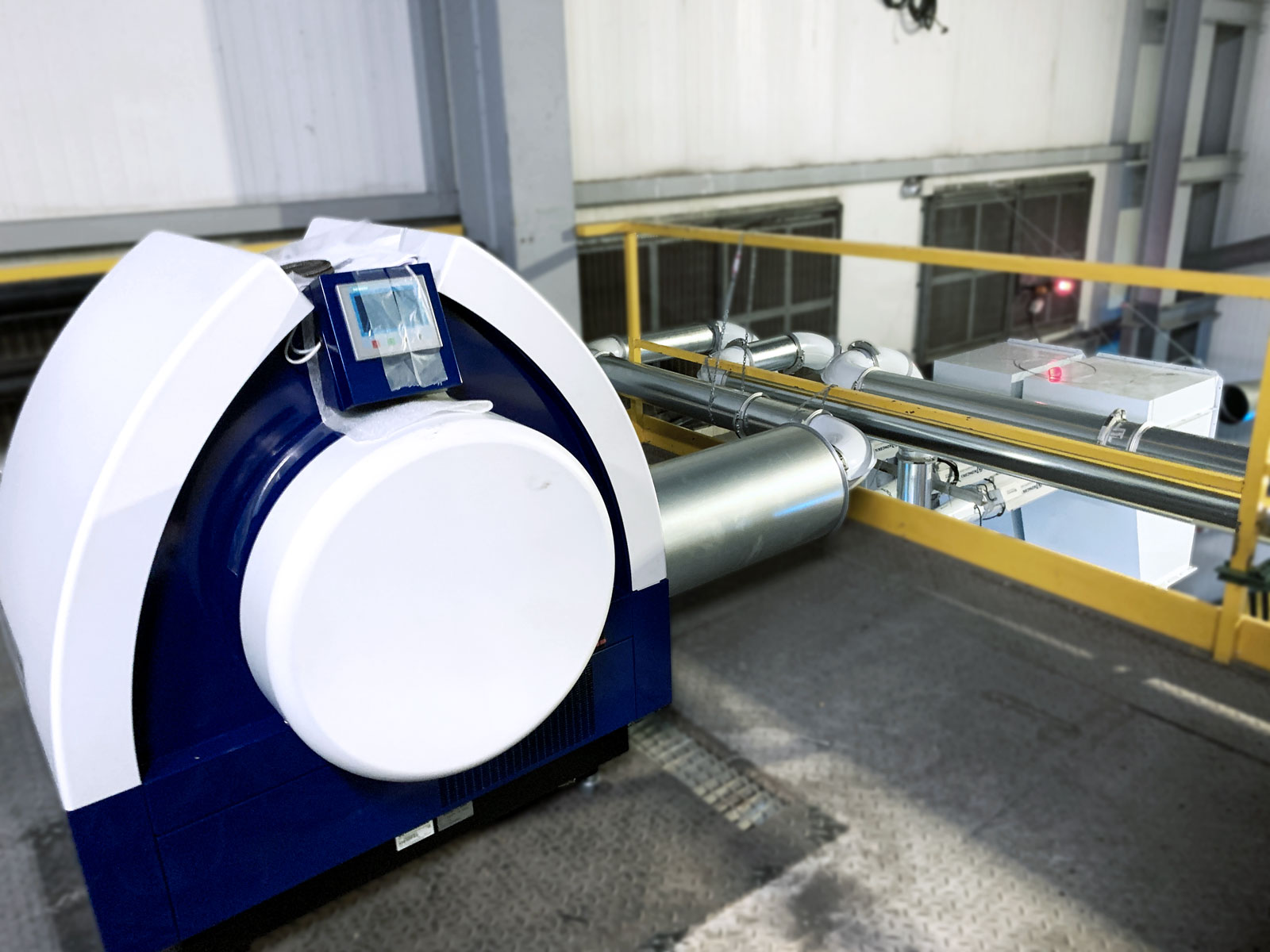

- Upgrade the power to the high-pressure blower, MultiAir FC2080T, equipped with a frequency inverter and soundproof design.

- Main equipment has been placed on the top floor of the client’s machines and each venturi system has been installed near the final section of the route, at approx. 1-2 meters before the static separator.

- Static separators have been chosen as the common discharge equipment.

The Advantages and Benefits

In the previous solution, the continuous trim sometimes was not properly discharged into the compactor and as a result of this, some quality rejects were provoked by jams on the rolls.

- ROI = 1.5

- Eliminated downtime (0% stops) by €40,000 annually.

- Reduced energy consumption by 60%, saving €22,000 annually.

- Cost savings of approximately €9,000 by removing compressed air.

- Reduced preventative and corrective maintenance costs by €9,000 – €12,000 annually.

- The smaller footprint of the MultiAir blower allows for optimized space management.

- Improved safety through reduction of noise pollution by 10% on the production floor.

- Risks of interventions mitigated.

Before Kongskilde’s Solution:

After Kongskilde’s Solution:

Download the full case study:

Featured Products

Contact us to start the conversation today.

Questions? Our world-class customer support and technical specialists can help.