The Challenge: Dusty Plastic Regrind Limiting Production and PIR Use

The manufacturer produces a wide range of automotive components—door panels, bumpers, HVAC ducts, and fluid systems. Their goal was to increase the amount of Post-Industrial Recycled (PIR) resin in finished products, but dust-heavy regrind plastic created recurring issues:

- Dust contamination restricted regrind plastic blending to only 30% PIR.

- Vacuum loader screens and filters clogged frequently, causing downtime.

- The existing granulator evacuation system released fugitive dust, creating housekeeping and safety challenges.

- Regrind injection moulding quality suffered, increasing part rejects and maintenance.

Any new system needed to support safe dedusting, improve dust collection around injection molding machines, and deliver a fast payback period.

The Facts: Material Characteristics and Process Requirements

Regrind Material Profile

- Material: HDPE regrind

- Bulk density: 35 lbs/ft³

- Particle size: ~3/8”

- Throughput: ~650 lbs/hr

- Application: Regrind material blended with virgin resin

Production Environment

- 30+ machine-side grinders, each requiring reliable dedusting

- High-volume regrind material plastic streams feeding molding operations

- Clear need for a system that prevents dust recirculation and improves material cleanliness

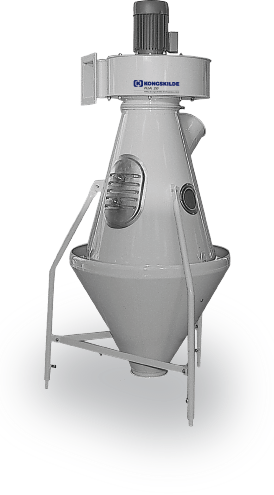

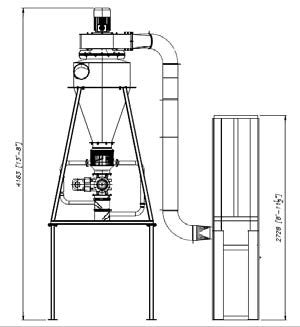

The Solution: Kongskilde AirWash Dedusting & Conveying System

The manufacturer installed the Kongskilde AirWash 50 paired with the K-200 dust collector, creating a fully sealed and efficient dedusting separator screen system for plastic regrinds.

How the System Works

- Material moves from each granulator through a Kongskilde OK pipe system into the AirWash.

- The AirWash uses negative pressure conveying, pulling dust inward rather than blowing it into the workspace.

- Plastic regrind does not go through the fan, preventing rotor wear and preserving particle integrity.

- A two-stage cleaning process removes dust and fines, producing clean regrind ready for blending.

- Conveying air is filtered through the K-200 baghouse, where dust is safely captured in steel cans with sight glasses.

Equipment Specifications

- AirWash 50 with 5 HP fan motor

- 0.75 HP rotary airlock for controlled discharge

- K-200 filtration system for dust collection

- Modular piping for easy installation across 30+ grinder stations

This closed-loop setup enabled safe dedusting, improved dust collection for injection molding operations, and ensured consistent regrind material quality.

The Advantages and Benefits: Higher PIR Use, Cleaner Production, and Safer Operations

Increased Recycled Material Incorporation

- After installation, the manufacturer increased PIR content from 30% up to 80% in select products

- Cleaner regrind plastic improved part quality and allowed more reprocessed material to be blended into the molding process

Reduced Downtime and Maintenance

- Screens and vacuum loader filters clogged far less frequently

- Stable, clean plastic regrind improved machine uptime

- Less wear on conveying components

Improved Worker Safety & Housekeeping

- Fugitive dust was eliminated at the source

- Cleaner floors, overhead structures, and equipment

- Improved respiratory health conditions for operators

- Lower insurance premiums due to reduced dust fire risks

Faster ROI and Lower Per-Piece Costs

- Rapid 6-month payback period

- Significant material cost savings from higher PIR usage

- Reduced labor associated with cleaning and dust management

- Lower overall cost per finished part

Before the Kongskilde system was installed, the granulator was evacuated with a “material-through blower” and open bottom cyclone. This process damaged the regrind and created additional dust. Only a minimal amount of fines ended up in the filter socks.

After the Kongskilde system was installed PIR content in select products went from 30% to 80%, leading to significant financial savings.

Download the full case study:

Explore Kongskilde Solutions for Plastic Regrind Cleaning

Kongskilde provides complete systems for plastic regrind cleaning, dedusting, and conveying—helping manufacturers reduce waste, improve product quality, and maximize the value of recycled resin.

Improve Your Plastic Regrind Quality and Dust Control

Ready to increase recycled material usage, eliminate dust, and improve your injection molding performance? Don’t hesitate to ask how we can help.