The Challenge

- This large French producer of yogurt had a wish to eliminate plastic waste from five production lines.

- At the same time, the company wanted to eliminate the manual work of regularly removing two plastic boxes per production line from the production area to the waste container.

- The yogurt producer wished to separate the different coloured stars (a “star” is the plastic off-cut in the middle of a yogurt 4-pack)

- The company had a cost of EUR 9,000 per month for transport and handling of unsorted bulk waste to the recycling company.

The Facts

- Material: Polystyrene

- Dimensions: Min. 8.5 x 8.5 mm, Max 20 x 20 mm

- Conveying distance: 30 meters

The Solution

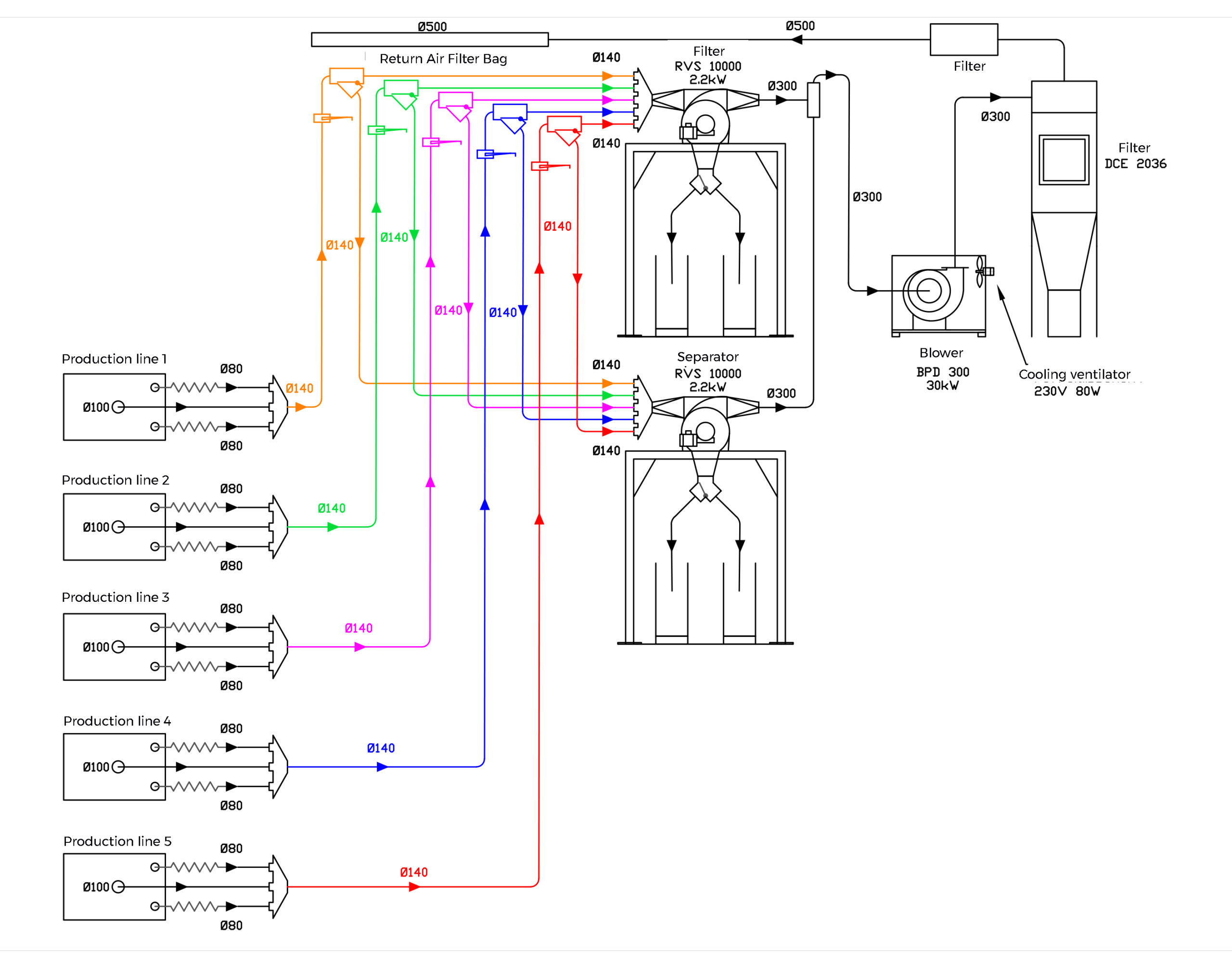

- The system consists of the Kongskilde MultiSeparator, the RVS, which enables the removal by suction of waste material from the 5 yogurt production lines.

- It comes with a BPD 30 kW blower, designed for handling of material through the blowers. It is equipped with a self-cleaning rotor, which has backward curved blades and an aerodynamic intake.

The Advantages and Benefits

- Over 8 tons of production waste material recovered and resold to raw material supplier at approximately EUR 200 per ton.

- Cost savings on waste treatment by recycling company.

- Waste material now conveyed directly into bigbags, saving EUR 9,000 per month due to lower transportation costs compared to whole containers.

- Expected payback time of less than three years.

- Individual conveying lines from each production machine make separation of different waste materials/colors possible.

- Elimination of staff requirement for internal transport of small containers from production area to outside containers.

Download the full case study:

Individual conveying lines from each production machine make it possible to keep different waste materials/colours separated.

After the Kongskilde system was installed the offcuts are now sorted in bigbags, resulting in significant monthly savings.

Ready to see more?

See how Kongskilde’s air-based solutions solved problems in different industries.