Air / Material Separators

STS Static Separators

Static separator placed at the discharge end of a pneumatic system

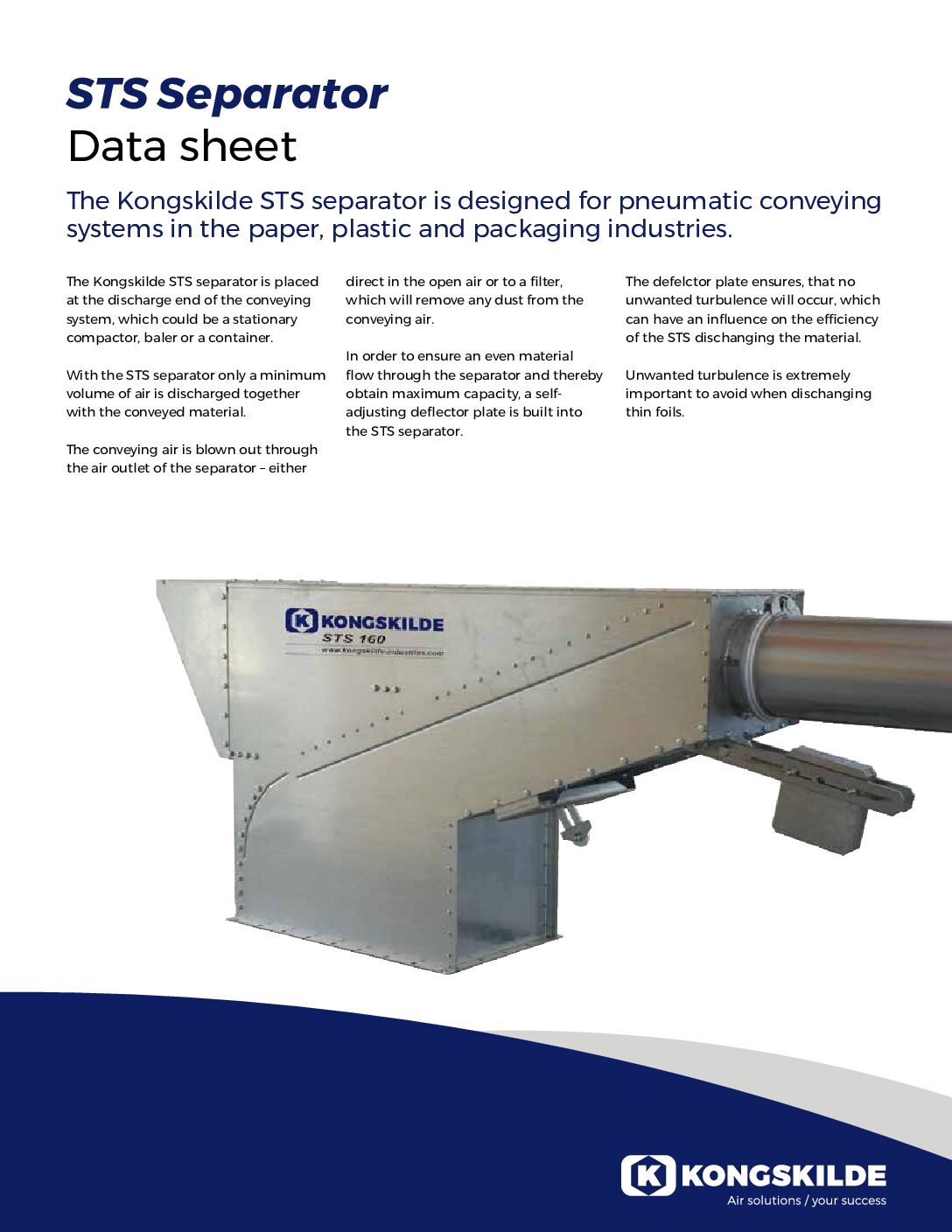

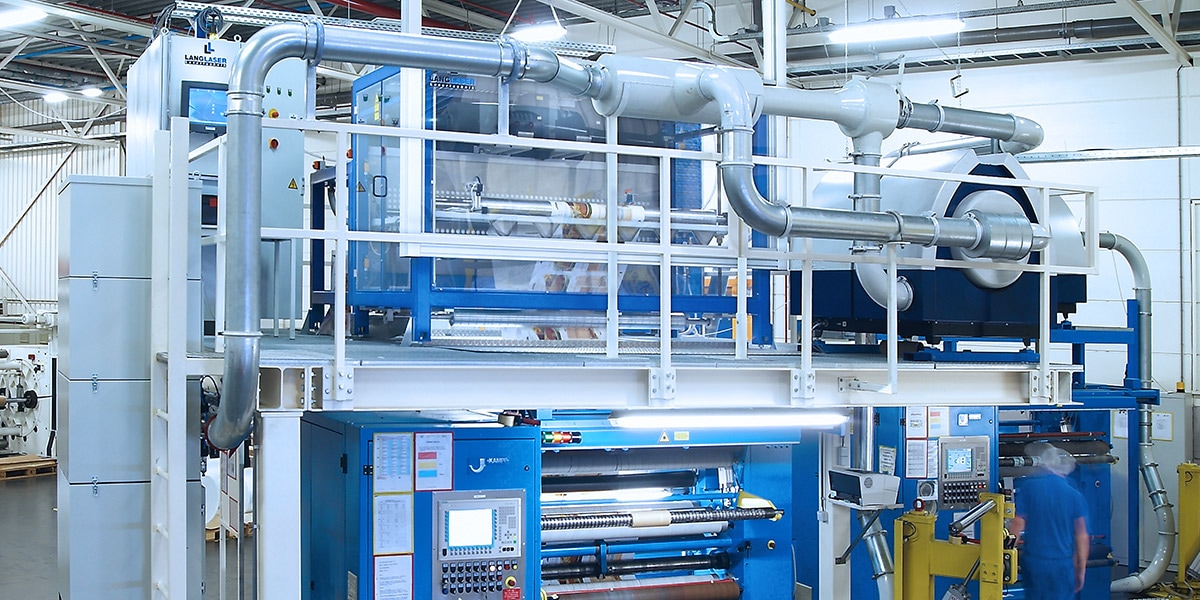

Kongskilde’s STS Static Separator is expertly designed to enhance pneumatic conveying systems by effectively separating materials from air streams. This reliable solution is ideal for industries that require precision and efficiency in material handling, such as paper, plastic, and packaging.

How the STS Static Separator Works

The STS Static Separator functions by being strategically placed at the discharge end of a pneumatic conveying system. It uses a self-adjusting deflector plate to ensure an even material flow, minimizing air volume discharge and maximizing separation efficiency. This setup prevents unwanted turbulence, which can disrupt the separation process.

Benefits of Using Kongskilde’s STS Static Separator

- Efficient Material Discharge: Ensures minimal air discharge with the material, enhancing system efficiency.

- Reduced Turbulence: The innovative deflector plate design prevents turbulence, ensuring consistent and reliable separation.

- Adaptability: Easily integrates with existing conveying systems and can be connected to filtration units to clean discharged air.

- Low Maintenance: Designed for ease of use with minimal upkeep required, supporting continuous industrial operations.

Downloads

Download data sheets, manuals, and spare parts lists for the STS Separator.

STS Static Separator Model Comparison

Compare available STS Static Separator models. Visit the downloads section for additional technical information.

| STS 160 | STS 200 | STS 300 | |

|---|---|---|---|

| Discharge Length | 381 mm | 306 mm | 307 mm |

| Discharge Diameter | OK200 | FK250 | FK300 |

STS Separator Videos

STS Static Separator Applications

Kongskilde’s STS Static Separator is specifically tailored for use in the paper, plastic, and packaging industries. It excels in systems where precise material separation is crucial, such as in recycling operations or during the processing of delicate materials. Its effectiveness makes it a vital component in maintaining the integrity and efficiency of industrial conveying systems.