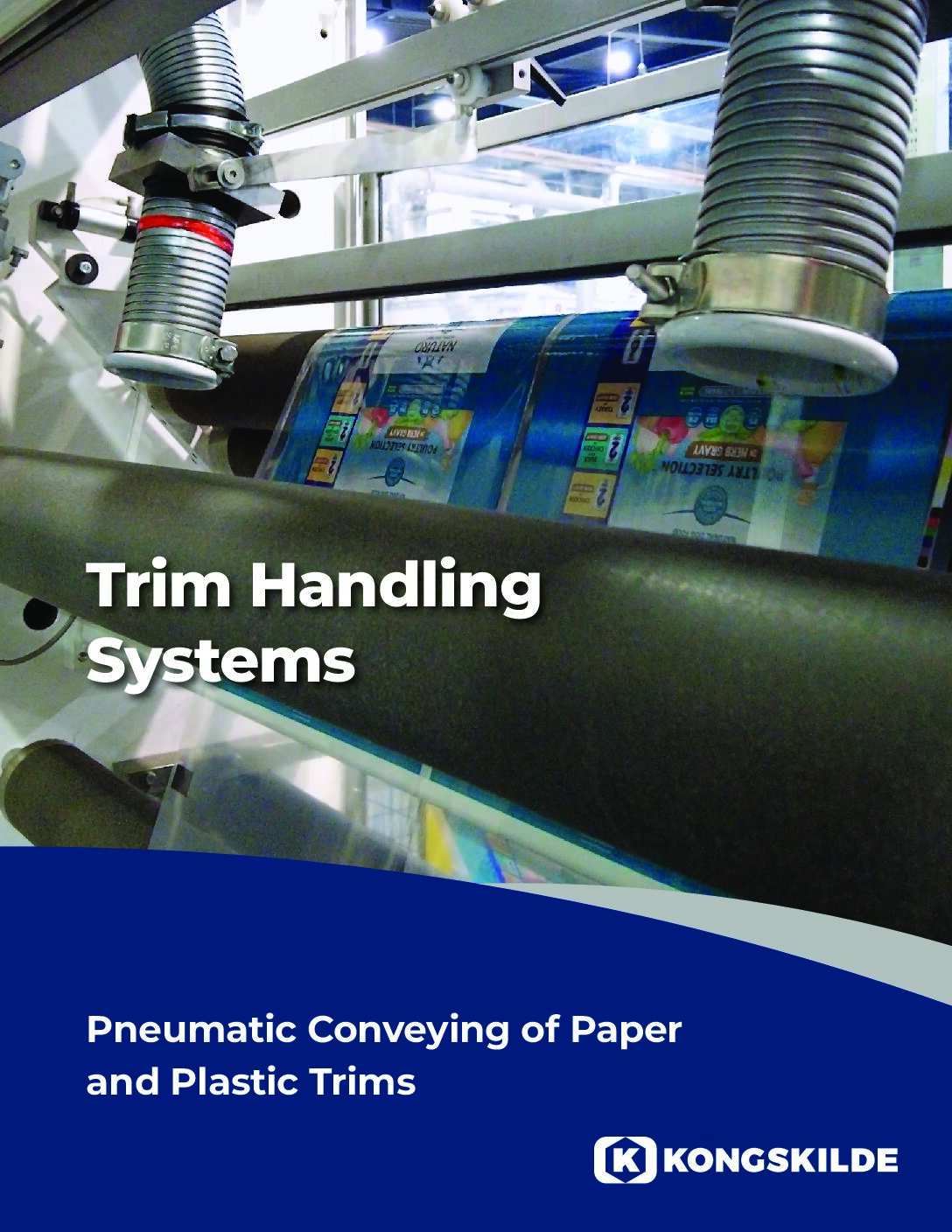

Trim Handling Systems

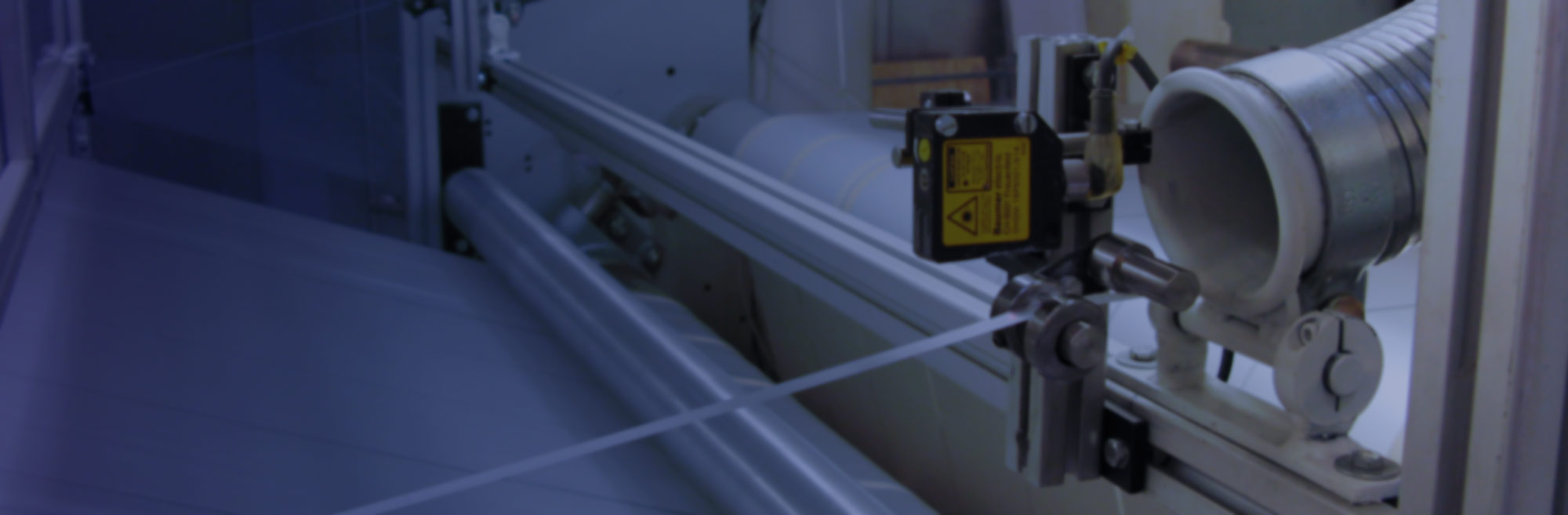

Optimize production capacity with an efficient trim handling system for modern processing lines involving paper, plastic, foil, and cardboard. For further information, contact us or select your solution below.

Finding the right trim handling system

We offer a variety of innovative solutions for conveying trim efficiently and reliably. At Kongskilde Industries, each trim removal system is designed to be cost-effective, low-maintenance, quiet, and adaptable—delivering proven results across a wide range of industries.

What is a trim handling system?

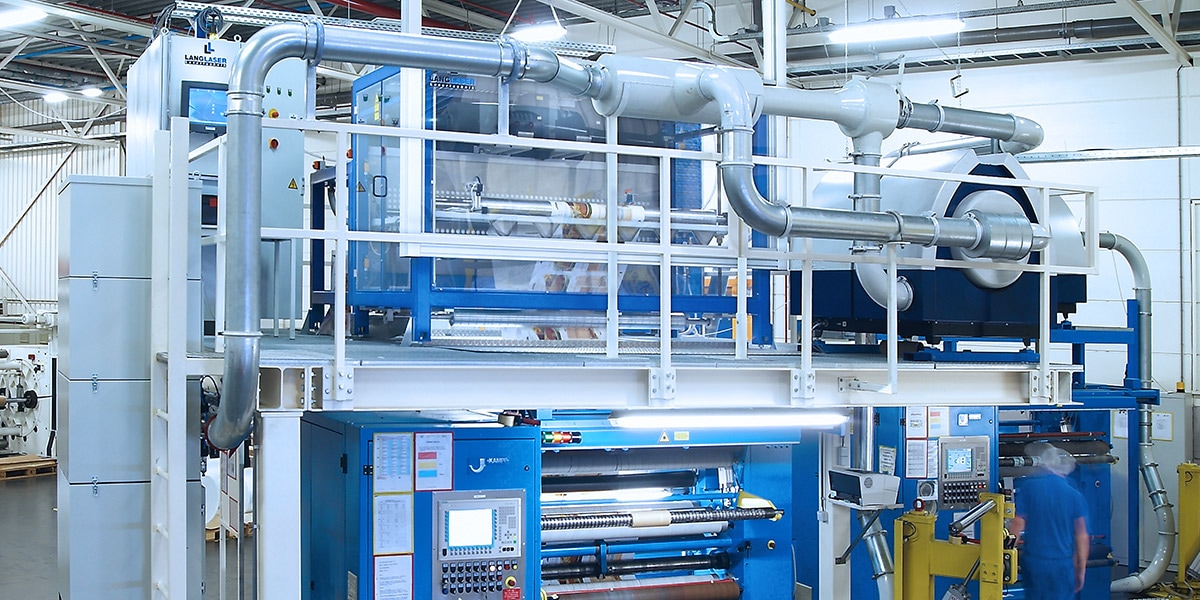

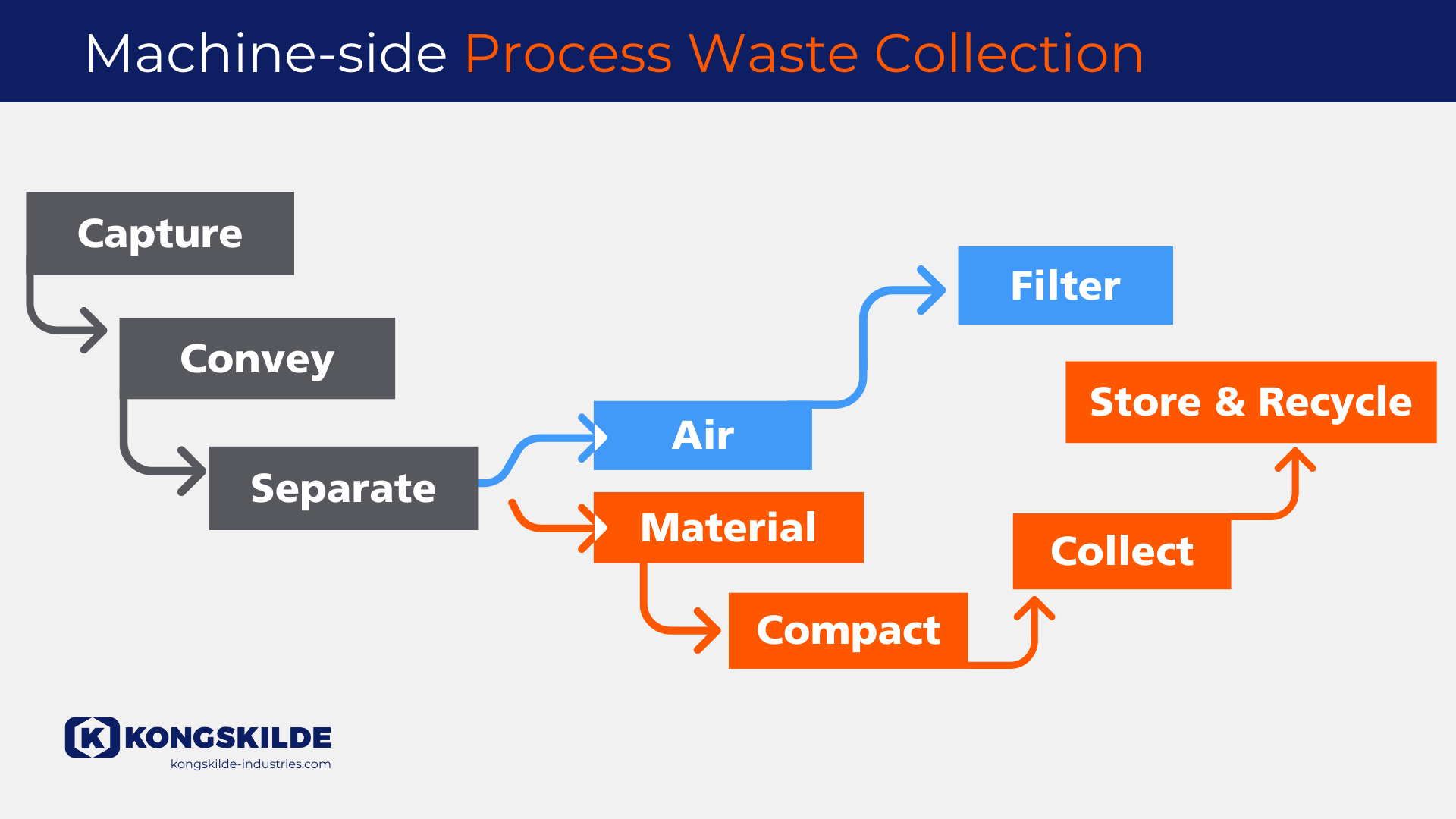

A trim handling system is engineered to extract and convey offcuts from materials like paper, plastics, foil, and packaging. This can include pneumatic transport of edge trims directly from the production line. Kongskilde provides tailored systems that allow trim to be efficiently collected and transferred from the point of generation to a centralized collection or processing unit.

There’s a growing shift toward vacuum-based trim removal systems in high-speed industrial settings, driven by the need for better energy efficiency, lower noise levels, and clean separation of recyclable waste streams. These systems often include downsizing of trim during conveying, improving overall waste management.

Why do materials need to be trimmed to begin with?

Trimming ensures clean, uniform edges to prevent mechanical issues such as press jams or misfeeds. For example, in printing and binding, paper is trimmed to exact sizes. In some cases, the trimmed material is reused; in others—especially with specialty papers—it may be discarded. An integrated trim removal system helps manage this material flow more effectively.

What components make up a trim handling system?

A typical trim removal system may use a combination of blowers and Venturis to create the vacuum needed for trim collection. Inline cutters, separators like Kongskilde’s RVS MultiSeparator, and flexible piping layouts help accommodate multi-machine setups and complex production spaces.

Depending on system design, trim can be conveyed to a single point or separated into different destinations. These components work together to provide a seamless, pressureless trim evacuation process.

What are the benefits of a trim handling system?

An effective trim handling system reduces material waste volume, supports longer conveying distances, and improves workplace safety and cleanliness. Vacuum-based trim removal systems offer quieter operation and eliminate dust issues in ducting—making them ideal for modern industrial facilities.

At Kongskilde, each trim solution is built for long-term performance and flexibility. Our systems are not only durable but can also be easily modified to adapt to changing production needs.

Questions?

Get in touch with our world-class customer support and technical specialists.