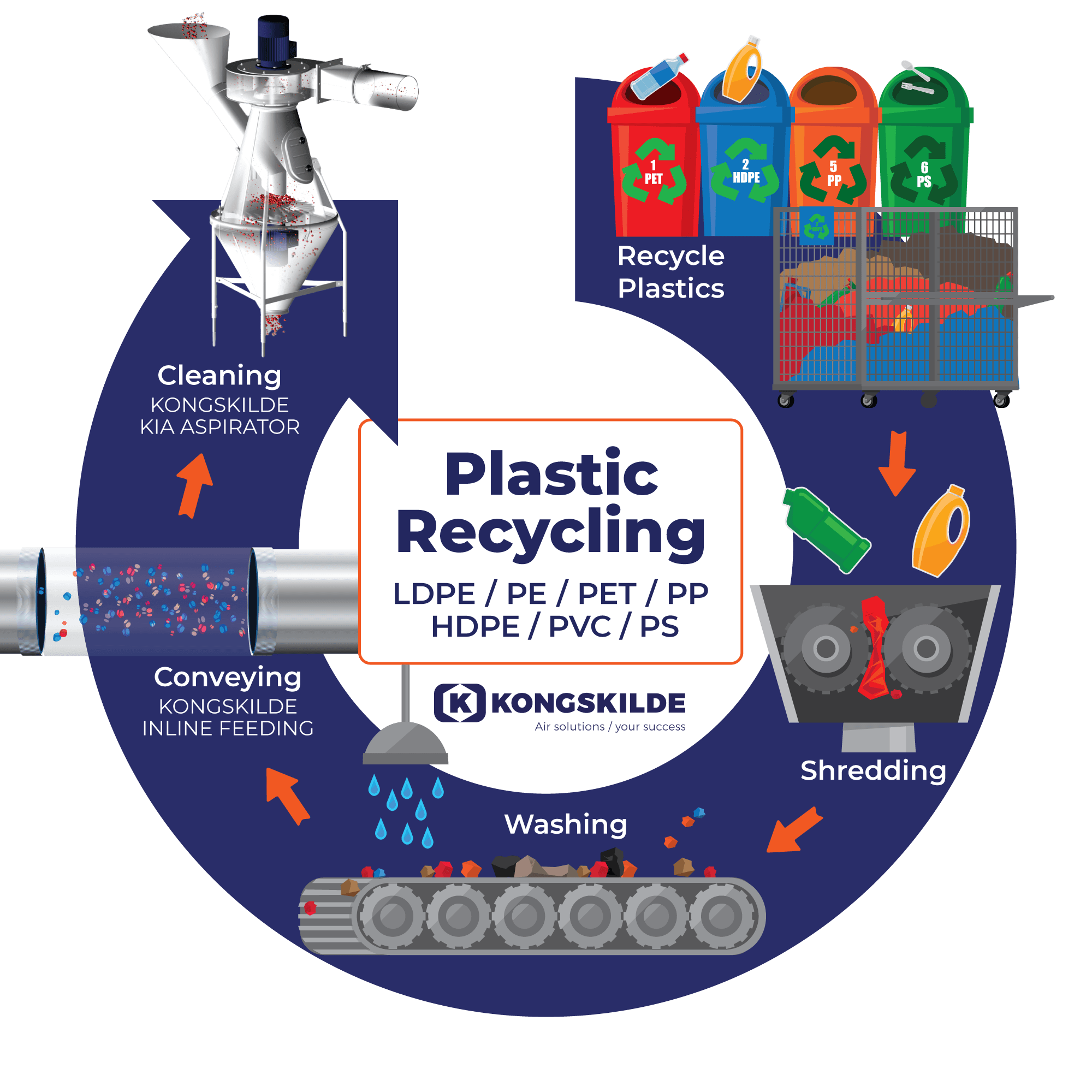

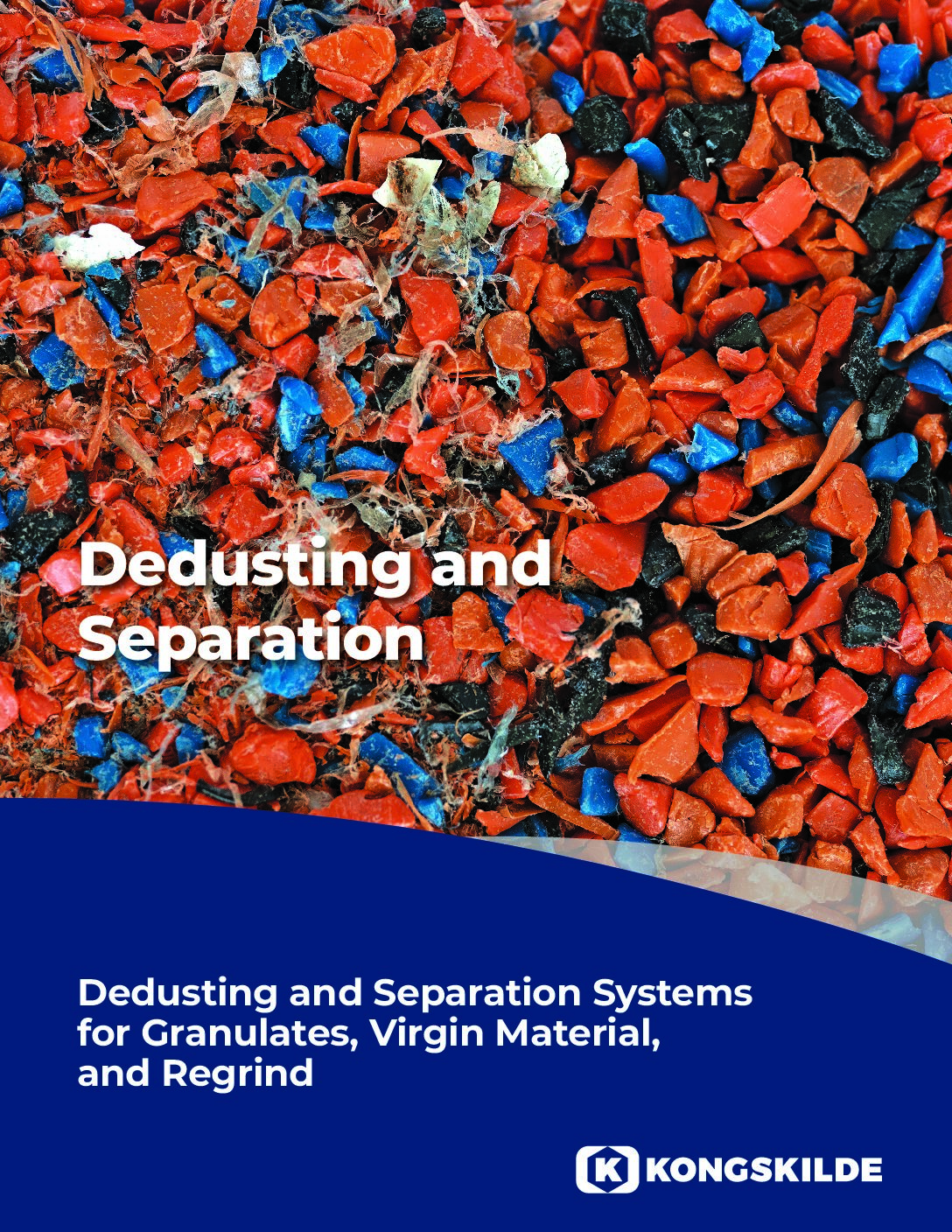

Enhance Material Reusability with Advanced Plastic Separation

Recycled materials often contain a mix of light impurities and dense plastic particles. Kongskilde’s innovative solutions for separating plastic for recycling are designed to improve the purity and value of your reprocessed materials.

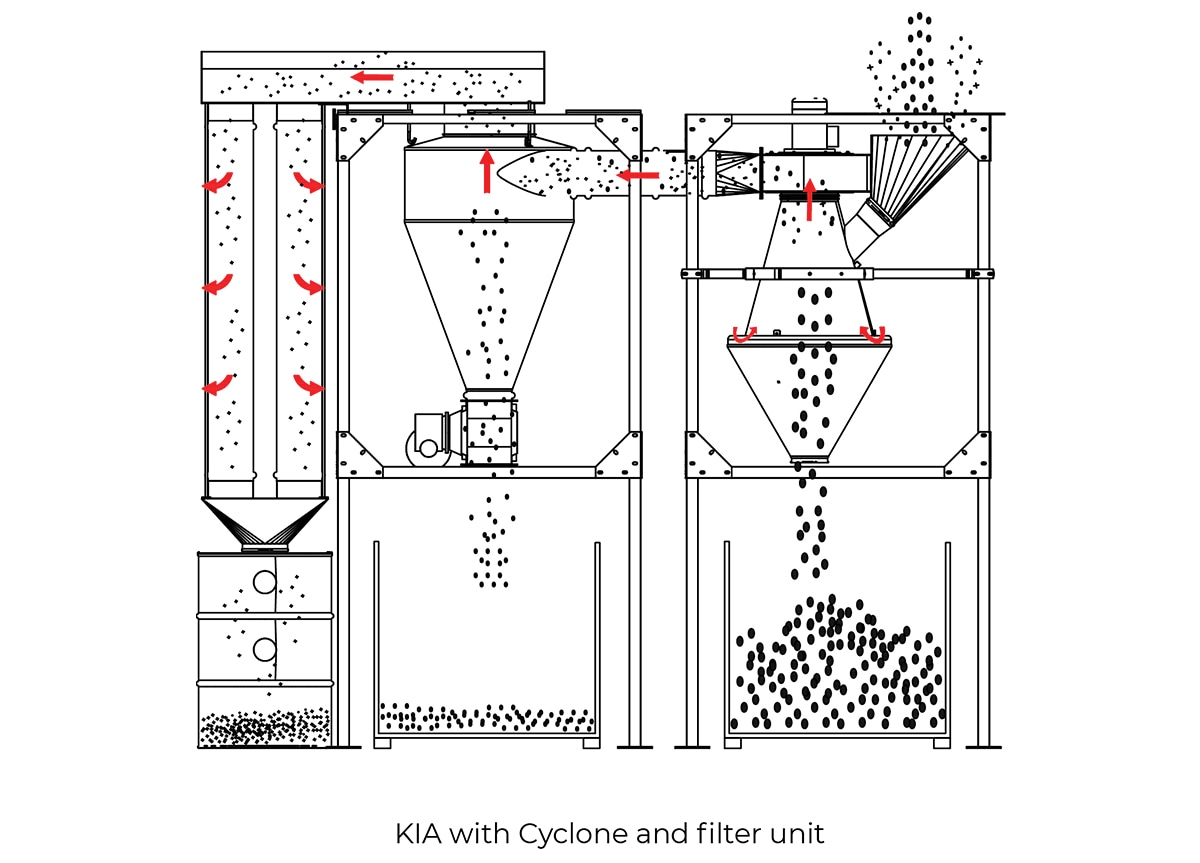

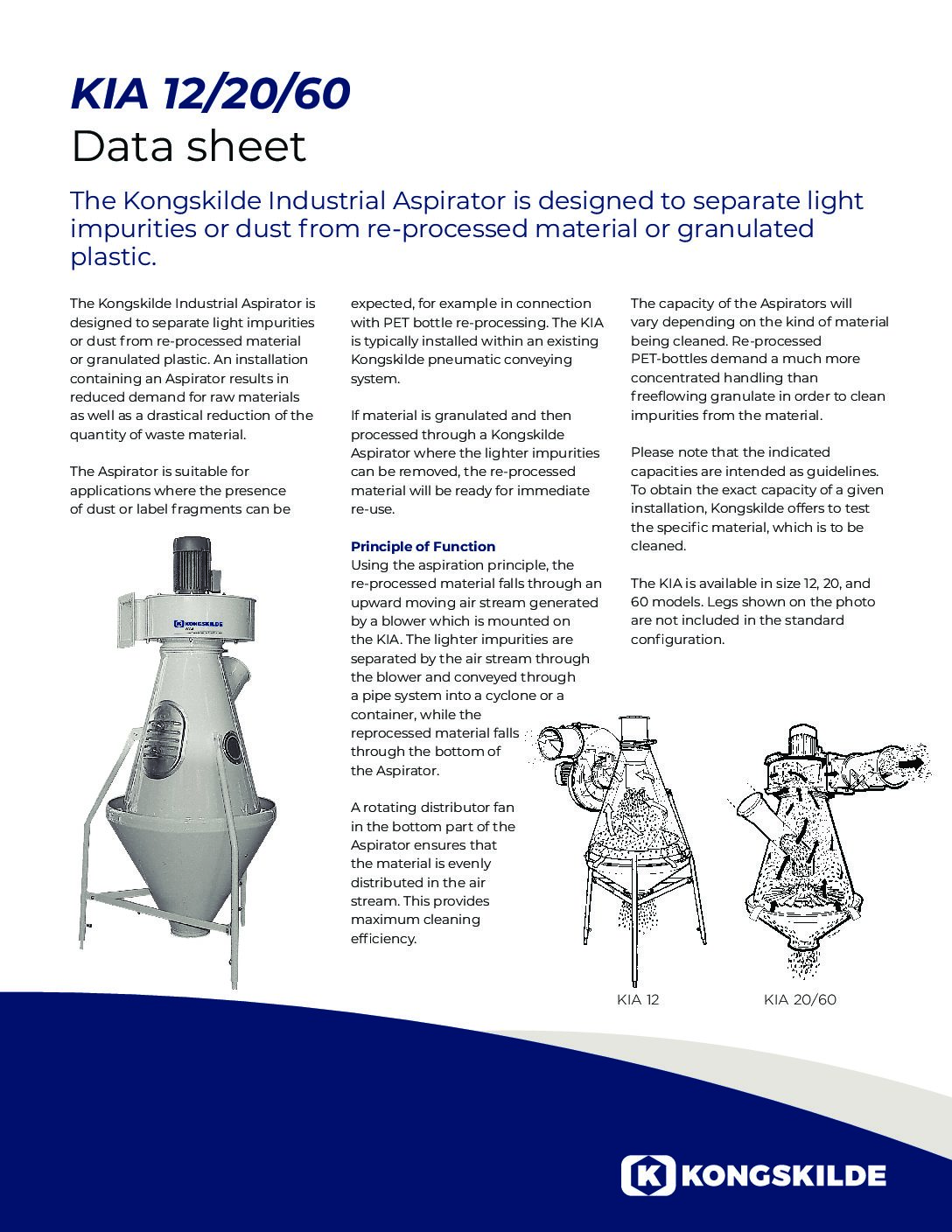

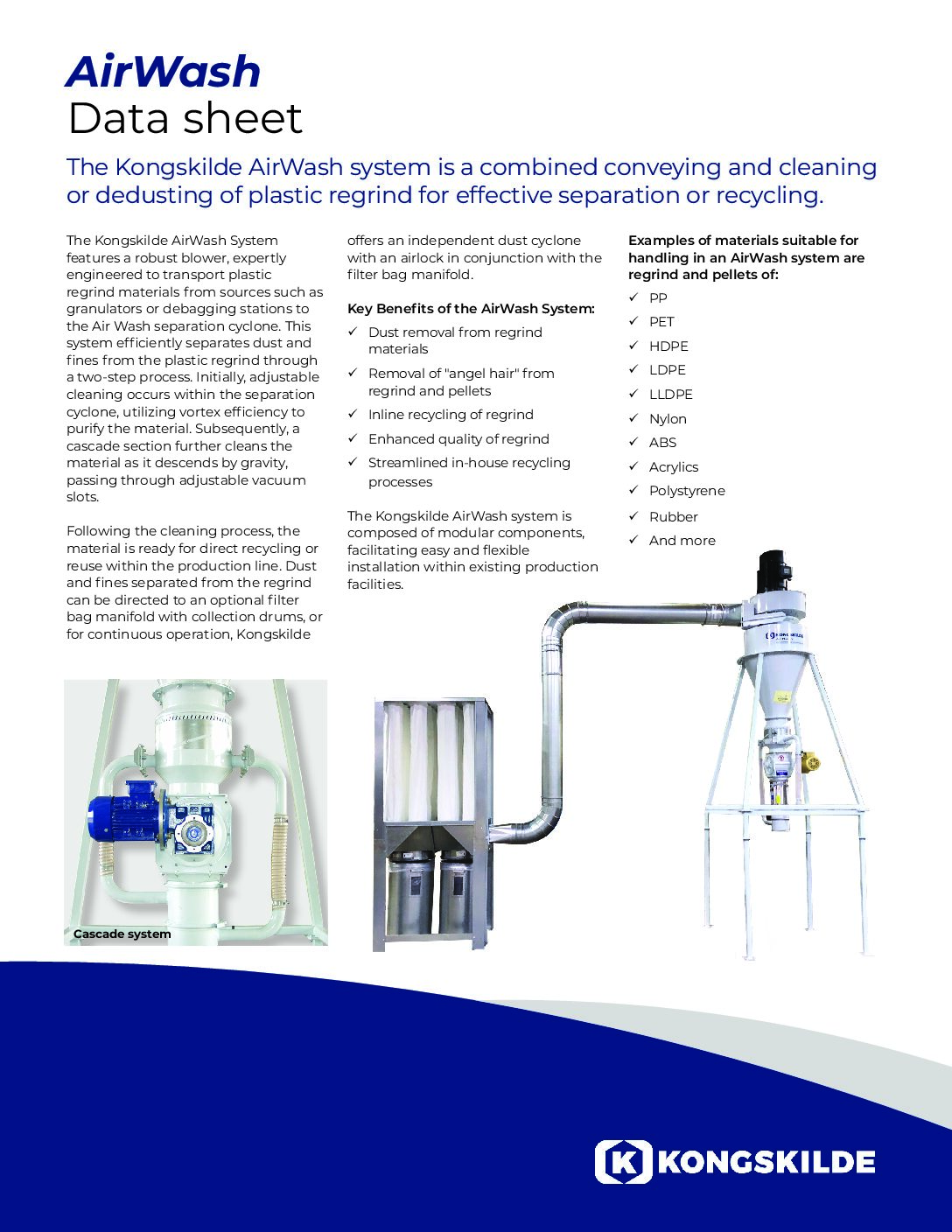

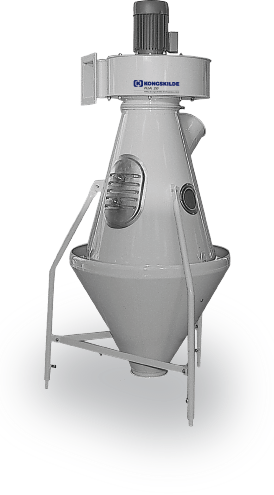

At the core of this process is the Kongskilde Industrial Aspirator (KIA) and AirWash™ systems. These units uses upward airflow to lift and extract lightweight contaminants, such as dust and fiber, from granulated or shredded plastic. The clean, reusable material is then discharged from the bottom outlet for further processing or reuse. This system is ideal for facilities focused on separating recyclable materials efficiently, safely, and with minimal manual labor.

“Minimizing and recycling production waste don’t just make good ecological sense, they’re economically meaningful objectives as well”

Julia Grosse-Wilde, Managing Director of the German Association of Plastics Converters

Kongskilde Material Separation Systems and Products

Our dedusting and plastic separation technologies are built to handle a wide range of recycled materials. Whether you’re separating plastic flakes, pellets, or shredded content, Kongskilde systems deliver consistent, high-quality output and a cleaner work environment.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Cleaning of Regrind Plastic Material in the Automotive Industry – USA

An automotive manufacturer in the USA needed a solution to remove dust from the work environment and increase the use of regrind material.