Significantly improve the quality and reusable percentage of re-processed materials, while also enhancing safety and the work environment.

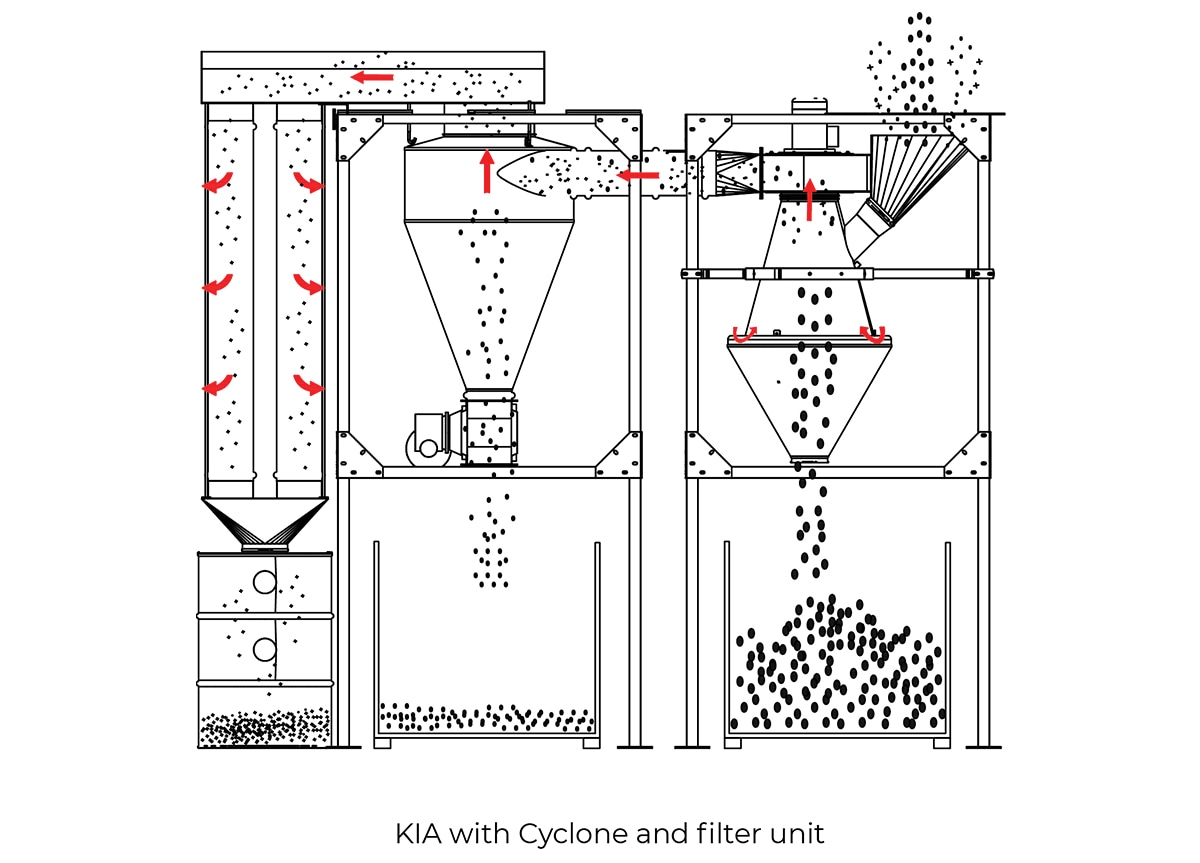

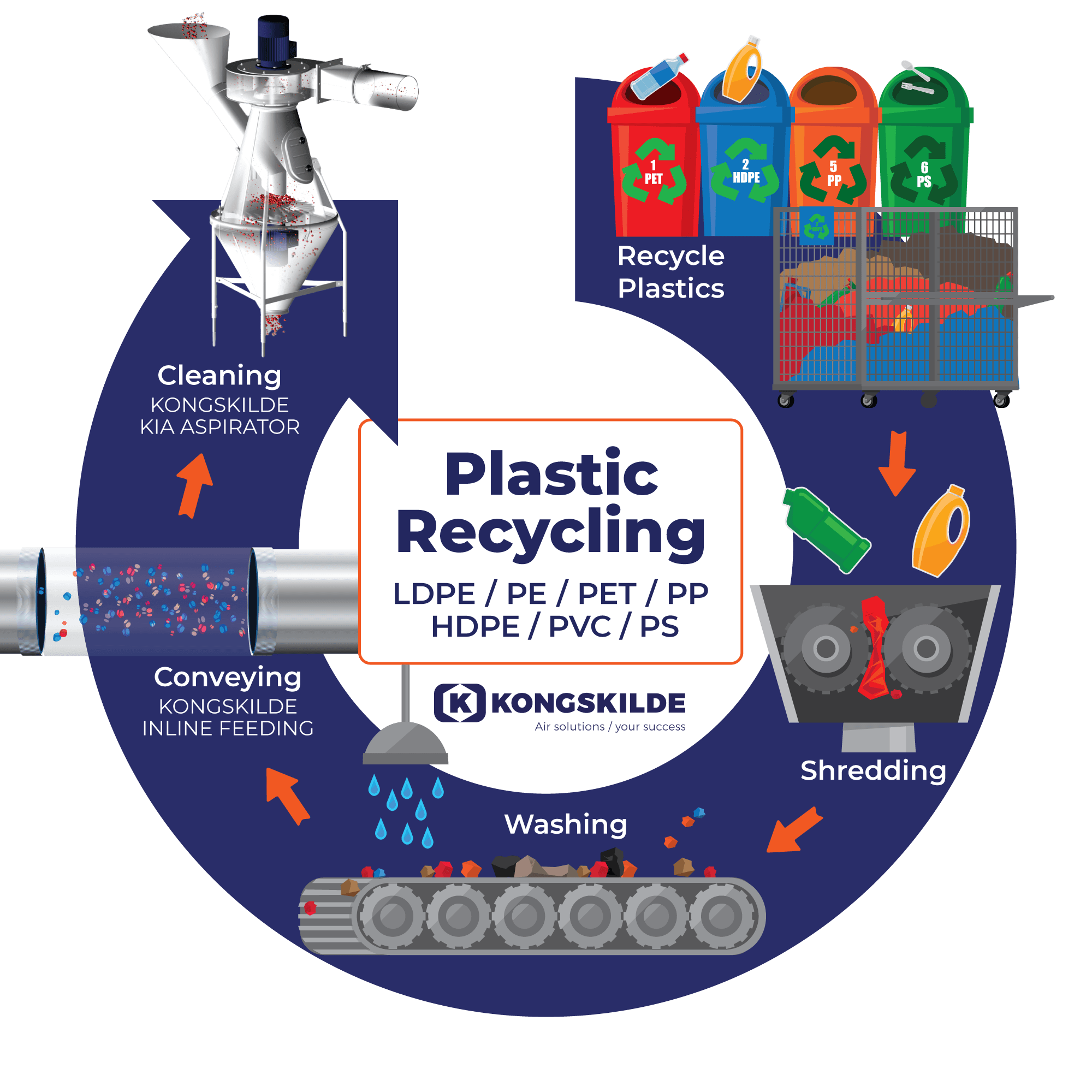

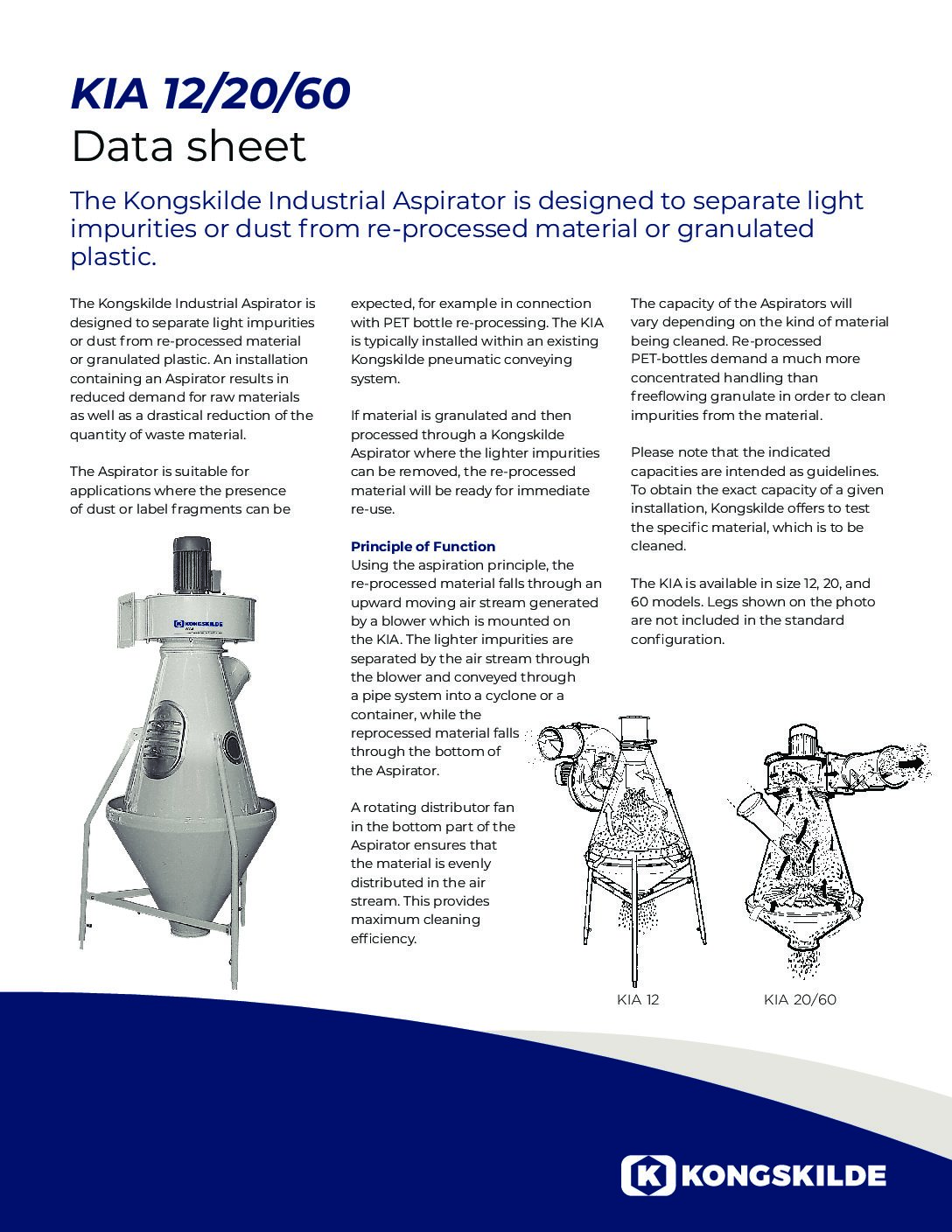

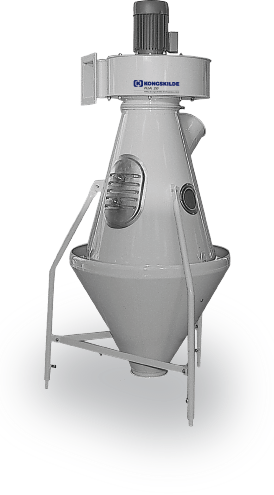

Many recycled materials are a mix of light and dense material, which can be turned into valuable reusable material after separation and dust collection. The Kongskilde Industrial Aspirator (KIA) uses innovative dedusting technology specifically designed to separate light impurities and dust from re-processed material or granulated plastic. The re-processed material enters the KIA via a gravity feed pipe into the main body where it enters an upward air stream. Lightweight impurities are removed and evacuated to the dust cyclone and filter socks using the top mounted fan. The remaining valuable material is captured via the bottom outlet of the aspirator and can be transported for re-use.

“Minimizing and recycling production waste don’t just make good ecological sense, they’re economically meaningful objectives as well”

Julia Grosse-Wilde, Managing Director of the German Association of Plastics Converters

Kongskilde Separation Systems and Products

Separation involves separating dust from re-processed materials, but it also encompasses the removal of light impurities. At Kongskilde Industries we offer various innovative dedusting and separation solutions.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Cleaning of Regrind Plastic Material in the Automotive Industry – USA

An automotive manufacturer in the USA needed a solution to remove dust from the work environment and increase the use of regrind material.