Kongskilde has been turning complex problems into simple solutions for over 75 years

Our secret? We’ve pioneered, simplified, and optimized the incredible power of pneumatic conveying. When it comes to transporting plastic and injection moulded components, our experience makes it look easy.

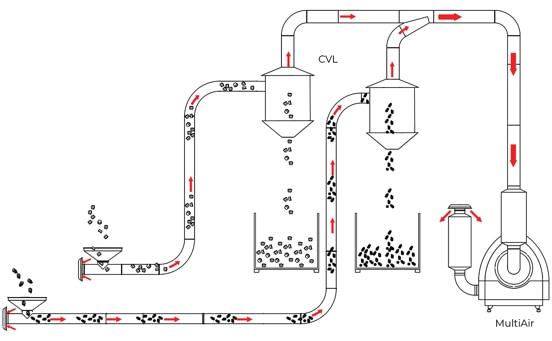

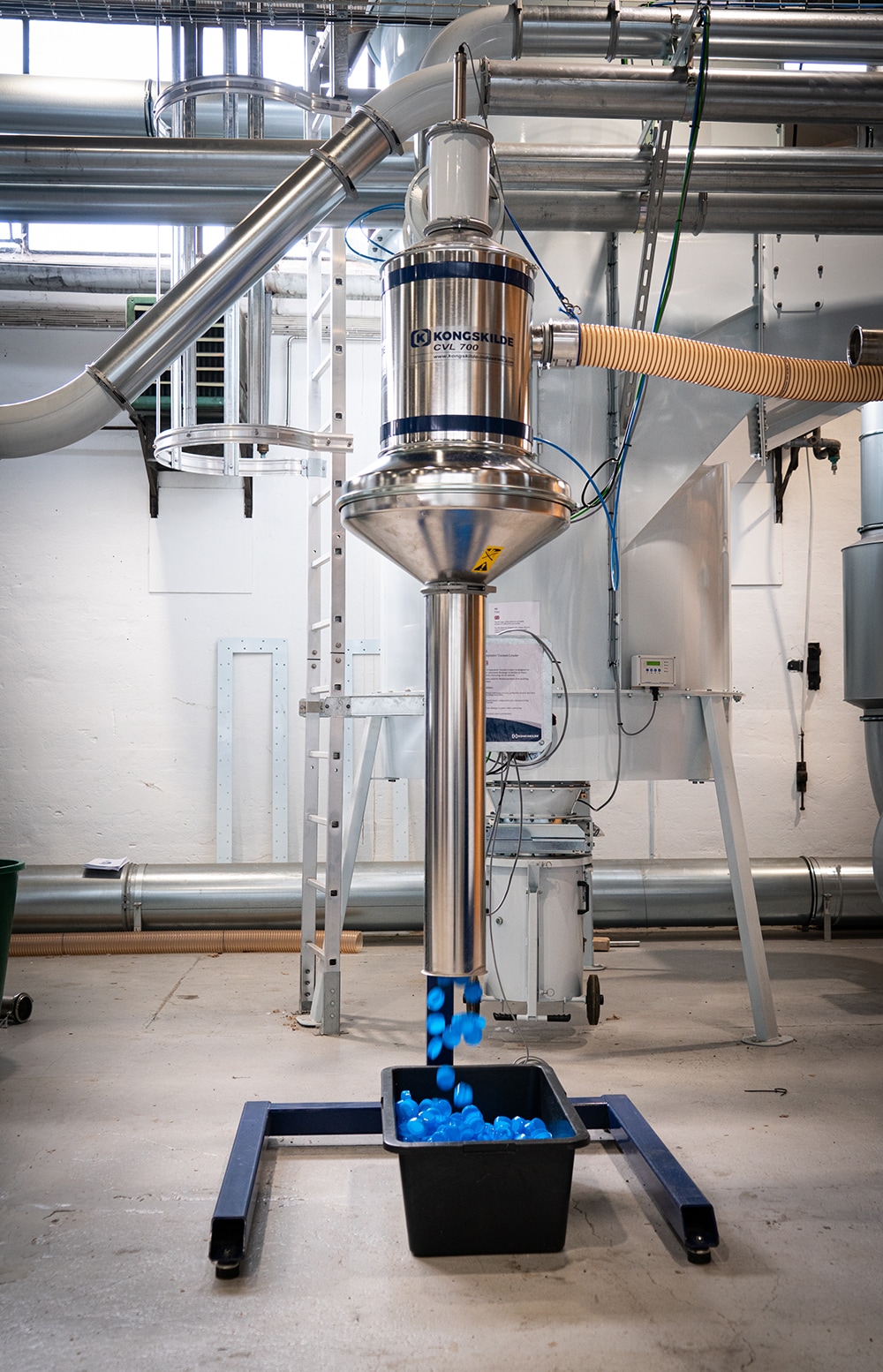

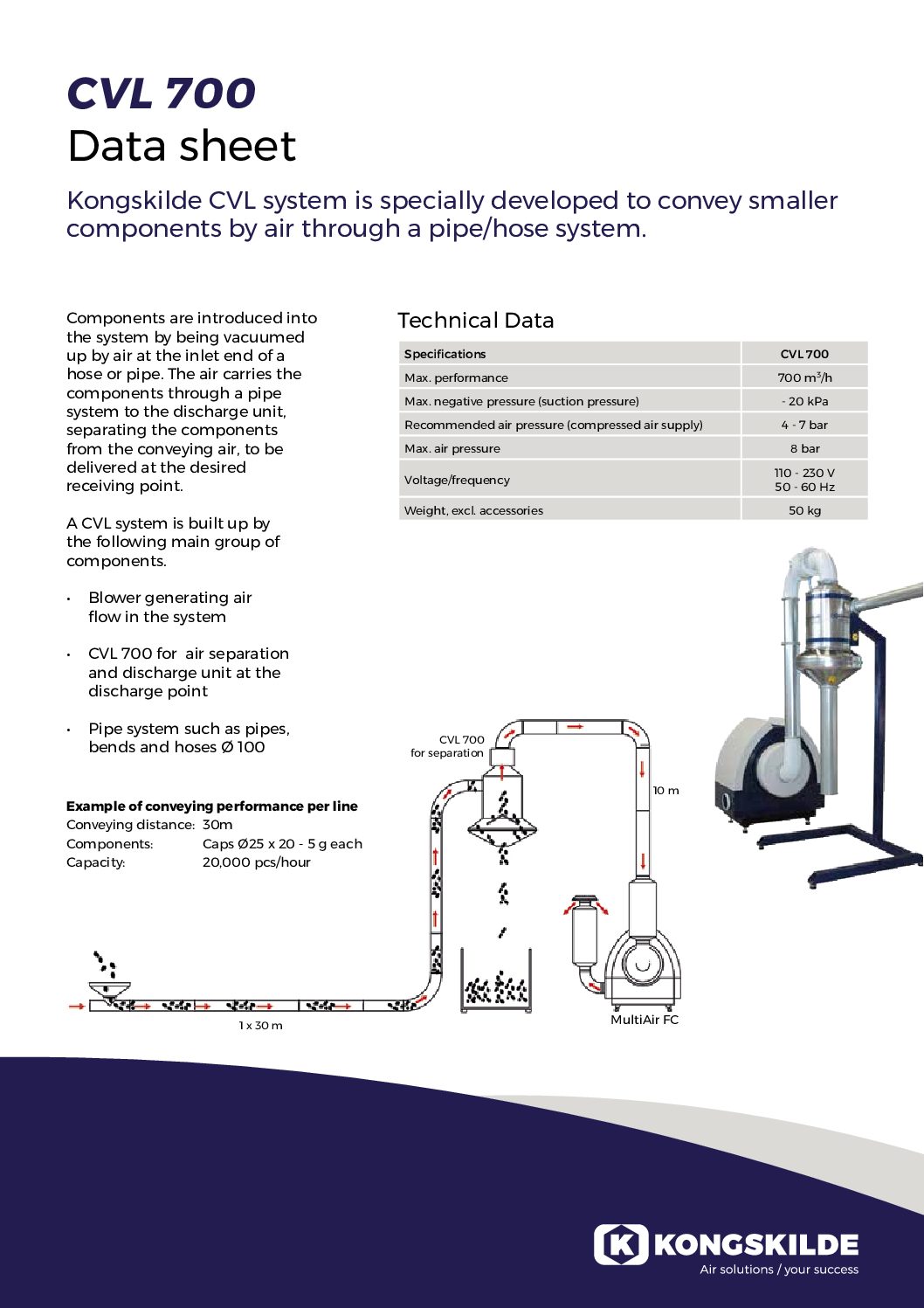

Plastic components begin their journey when vacuumed up at an air powered inlet. The air carries the components through a pipe system to the discharge unit where it releases the components from the conveying air and ultimately delivers them to the receiving point.

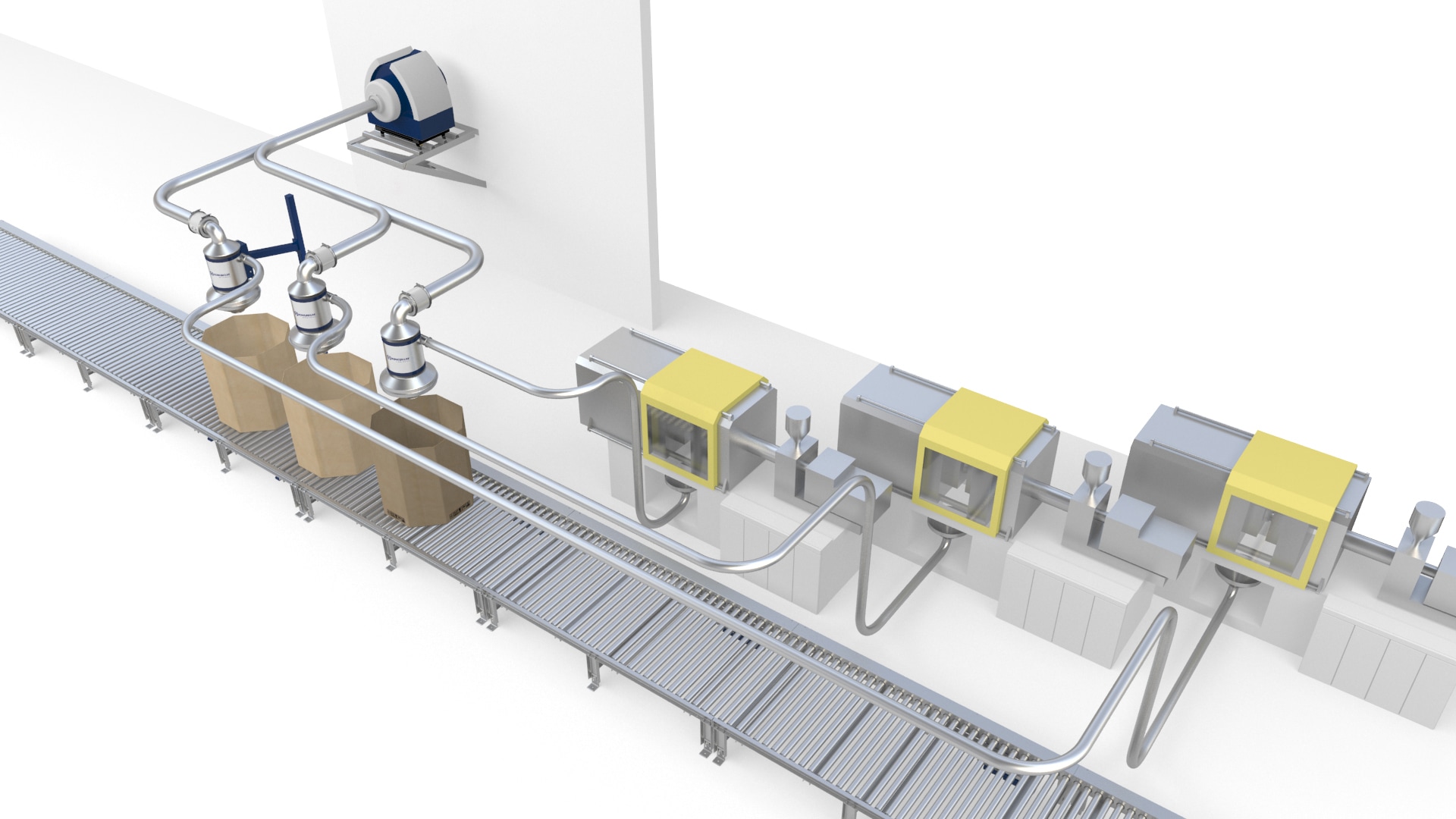

Our system is incredibly modular and based on a wide range of standardized components. This allows for supreme flexibility in the system layout and makes it easy to install our pneumatic conveyor solution anywhere, especially where floor space is limited.

Automate the movement of plastic components

Say goodbye to space-consuming, maintenance-heavy, and operator-requiring mechanical systems! Longer conveying distances become possible, while production space is freed up.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Pneumatic Conveying of Bottle Caps – Europe

The company requested a system that would cut away the logistics of having a forklift operator transport pallets back and forth to save time and increase safety.