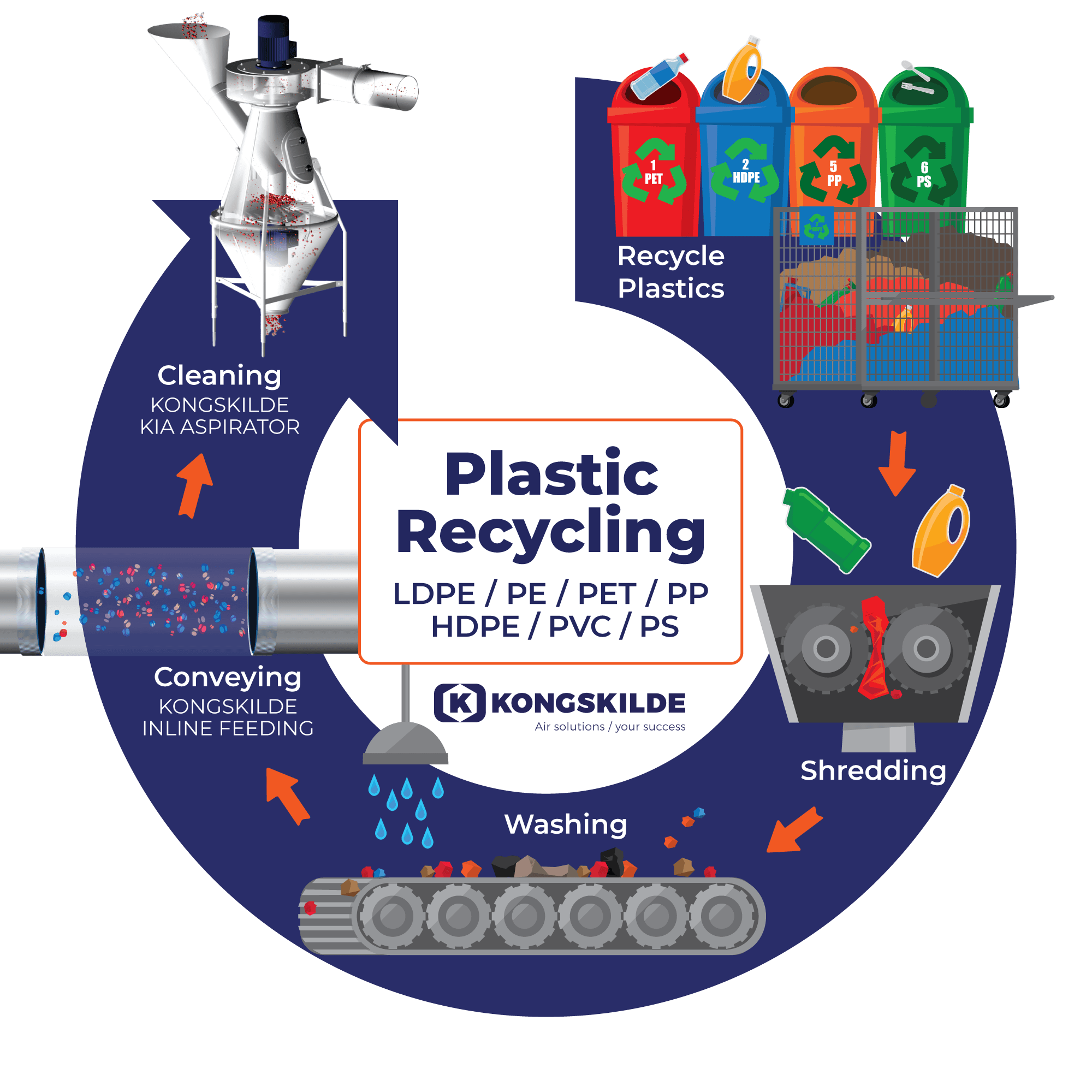

Dedusting and Separation Systems

Dedusting and separation systems can be added to the recycling process to improve the quality of recycled material and free the working environment from dust and impurities. For further information contact us or select your solution below.

We offer various solutions to remove dust and contamination

Whether the case involves pellets or granulated regrind, dust and contamination can negatively affect the processing of materials and cause rejections in the manufacturing or recycling line. Kongskilde Industries offers various solutions to remove these, and other inconveniences.

What is dedusting and separation?

Dedusting is the industrial cleaning of granulates, generally using some form of pneumatic separation system. Separation may involve separating dust from re-processed materials, but it also encompasses the removal of light impurities. At Kongskilde Industries we offer various innovative dedusting and separation solutions, which can all be found on this page.

Why does dedusting and separation take place?

Dedusting and separation systems are designed to remove or reduce dust, fine particles and other potential contaminants, or separate dissimilar materials. This is done to improve the overall material quality and value, as well as to maximise production efficiency. Dust is the most common fine impurity which attaches to pellets or granules: a functional dedusting and separation system will also minimize the potential of dust being expelled into the workplace.

What materials are handled by these systems?

In terms of the materials being handled, notable applications of dedusting and separation systems include granulated and virgin materials, such as rubber, PP, PET, PE, HDPE, Nylon, ABS, and carpet fibres.

Recycled materials can become valuable reusable material after the separation process has taken place. Material can also be evacuated from granulators, mixers and other process equipment using particular solutions. The recycling process and work environment can therefore greatly benefit from dedusting and separation systems.

How many system options are there?

Various forms of dedusting and separation systems exist. For example, pneumatic separation solutions are used as a gentle, yet effective approach to the dedusting of pellets. Kongskilde’s AirWash system is a precise de-duster that can convey and clean simultaneously. This is only one example, so we welcome you to consider the details of the available options below.

What are these systems composed of?

Common components of dedusting systems include aspirators, cyclones, and piping. Airflow allows for the evacuation of lightweight impurities to dust cyclones and filter socks, while the re-processed material makes its way to the bottom outlet of the aspirator. Dedusting and separation systems tend to be connected with material handling and processing systems and can be installed or retrofitted to existing production environments.

Finding the right system for your manufacturing or recycling process

Having the right system in place will decrease rejection rate, improve efficiency and product quality, increase market and production value, and reduce maintenance and downtime. This is because if materials are not dedusted, residual dust may make its way into other equipment, resulting in blockage of filters and screens – which will have a negative impact on production effeciency.

Questions?

Get in touch with our world-class customer support and technical specialists.