Air / Material Separators

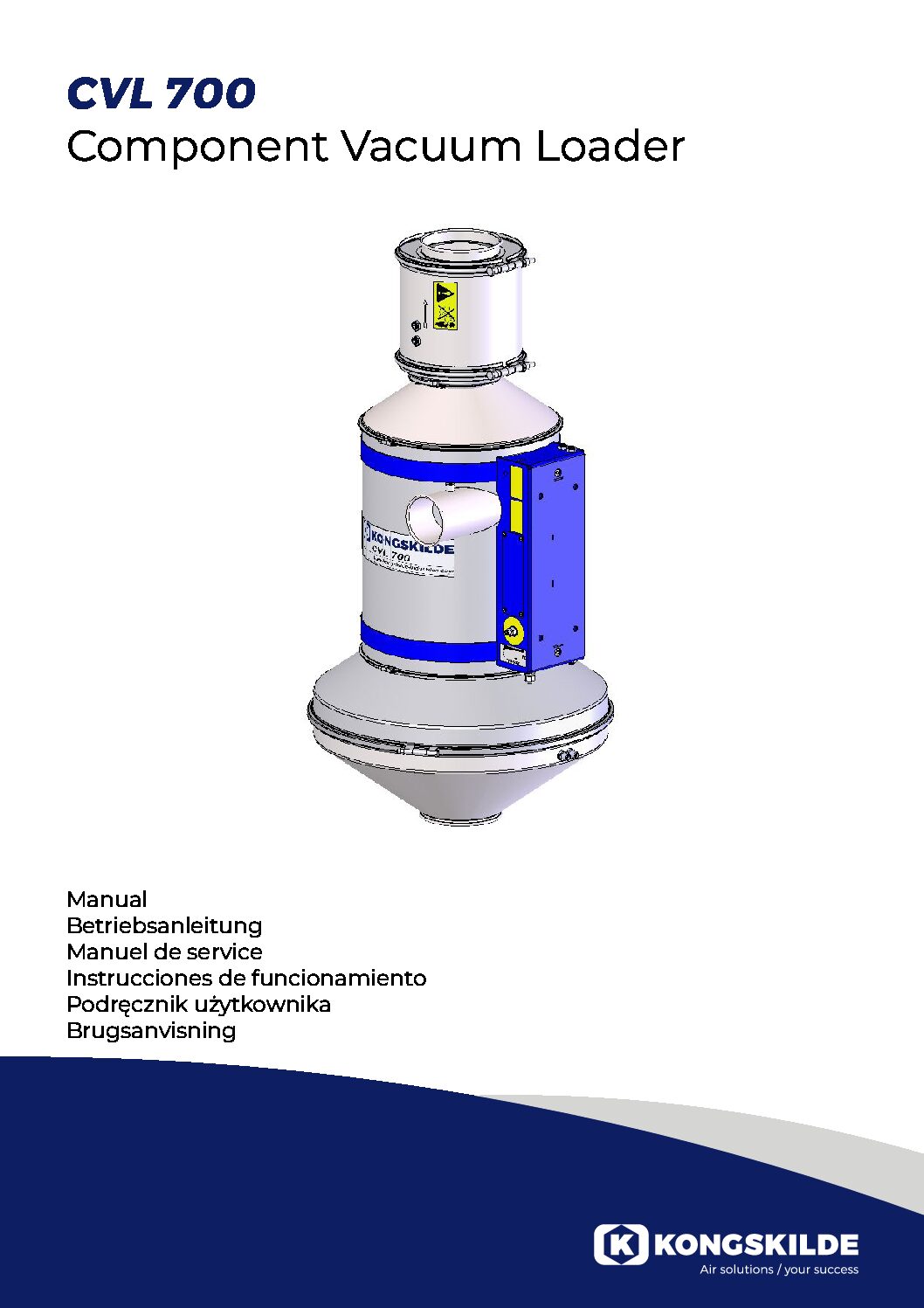

CVL Component Vacuum Loader

Streamlines pneumatic conveying for batches of finished components

The CVL Component Vacuum Loader is an advanced industrial vacuum loader that streamlines pneumatic conveying of finished plastic components, making material handling efficient and reliable for high-precision manufacturing environments. Designed to integrate seamlessly with Kongskilde Industries’ conveying systems, the CVL simplifies the transport of injection-molded parts—such as caps, closures, and other molded objects—directly to assembly or packaging lines, offering precision batch delivery across large-scale operations.

Designed for Seamless Material Handling

The CVL vacuum loader is developed to enhance material handling by automating the movement of small components within manufacturing facilities. This compact system can pick up, convey, and discharge batches over both short and long distances, ensuring materials reach their intended locations quickly and efficiently. Ideal for manufacturers seeking to optimize workflows, the CVL replaces manual handling and reduces reliance on bulky mechanical equipment.

How the CVL Industrial Vacuum Loader Works

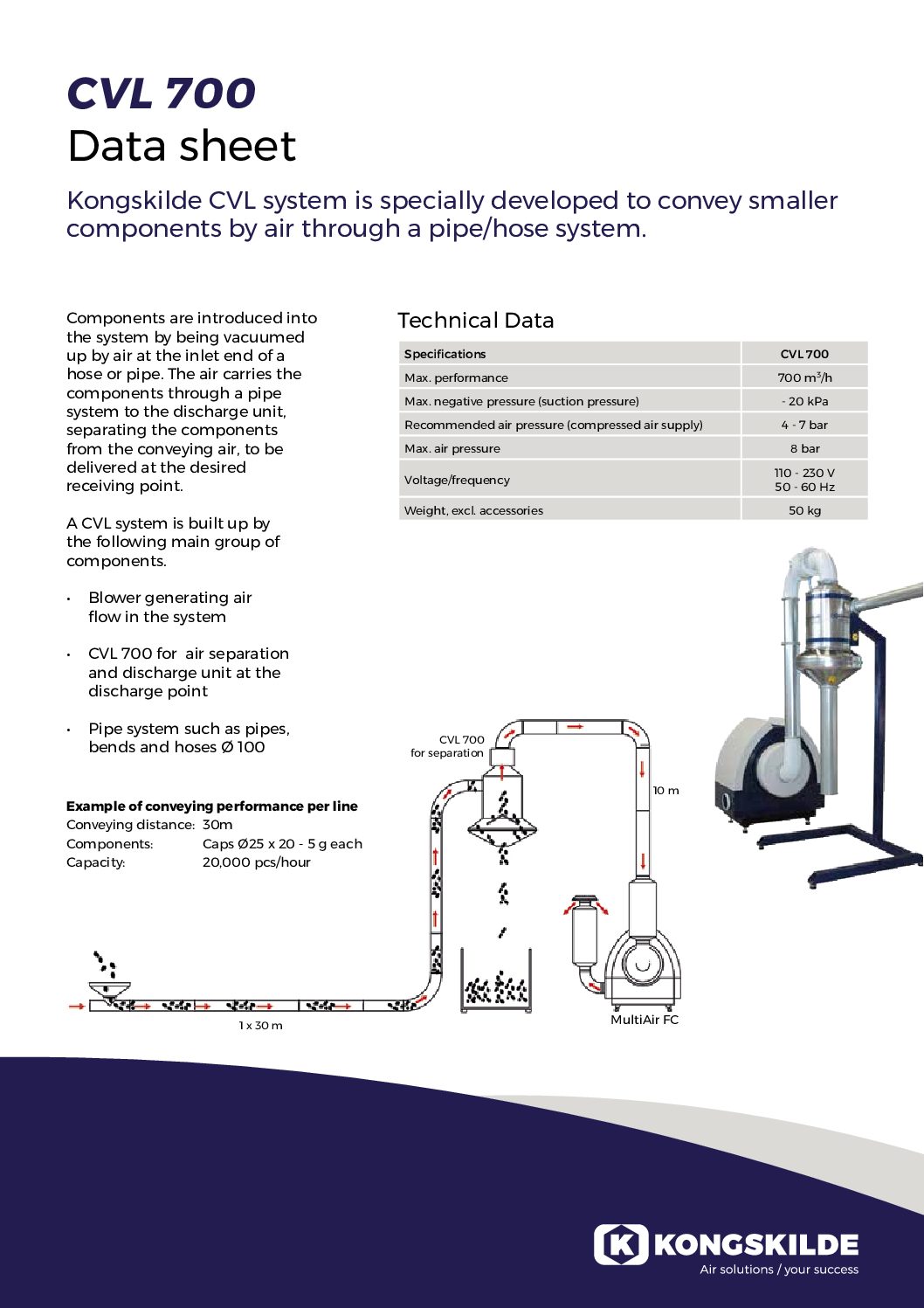

The CVL operates using high-efficiency, pressure-controlled MultiAir FC blowers (frequency controlled) that are coupled with a vacuum gate collection system. This setup enables the controlled pick-up, transport, and release of materials in organized batches, supporting reliable and consistent delivery to storage areas, assembly lines, or silos. Additionally, the vacuum loader is especially suited for conveying injection-molded parts in a precise sequence, optimizing the flow of materials through each step of the manufacturing process.

Key Features of the CVL Industrial Vacuum Loader

Designed with advanced features, the CVL vacuum loader is built to meet the demands of modern manufacturing environments:

- High-Efficiency Blowers: Utilizes frequency-controlled MultiAir FC blowers for energy-efficient performance.

- Flexible Conveying Range: Capable of conveying materials up to 100 meters, adapting to various production floor layouts.

- Batch Discharge System: Organizes and discharges materials in batches, streamlining workflows and improving production efficiency.

- Pressure-Controlled Operation: Precision pressure control ensures safe and effective handling of components.

Integrated Design: Easily connects with existing Kongskilde conveying systems, facilitating smooth integration into production lines.

Benefits of Using the CVL Industrial Vacuum Loader

The CVL offers substantial benefits for manufacturers, transforming material handling processes with automated precision and reliability:

- Automation of Manual Tasks: Reduces or eliminates the need for manual transportation of items between departments, improving workflow and reducing labor costs.

- Replaces Traditional Equipment: Serves as a more efficient alternative to conveyor belts and other mechanical handling tools, saving floor space and reducing maintenance.

- Cost-Efficient Operations: By automating material handling and reducing downtime, the CVL lowers operational costs and enhances productivity.

- Enhanced Safety: The vacuum loader’s design minimizes manual handling, contributing to a safer work environment by reducing the need for hands-on material movement.

Downloads

Download brochures, manuals, data sheets, and spare parts lists for the CVL.

Videos

CVL Component Vacuum Loader Applications

The CVL Component Vacuum Loader is ideal for various applications across industries where precision and efficiency in material handling are crucial: