Conveying Blowers

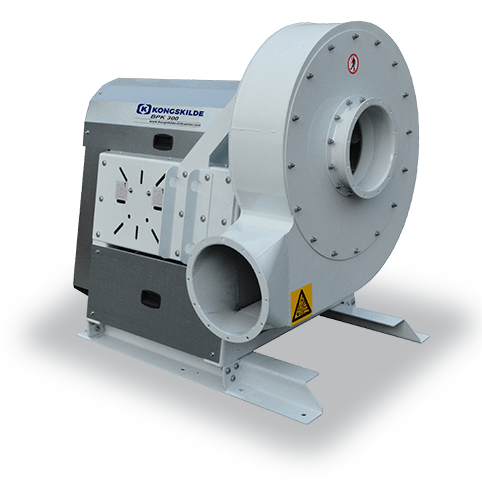

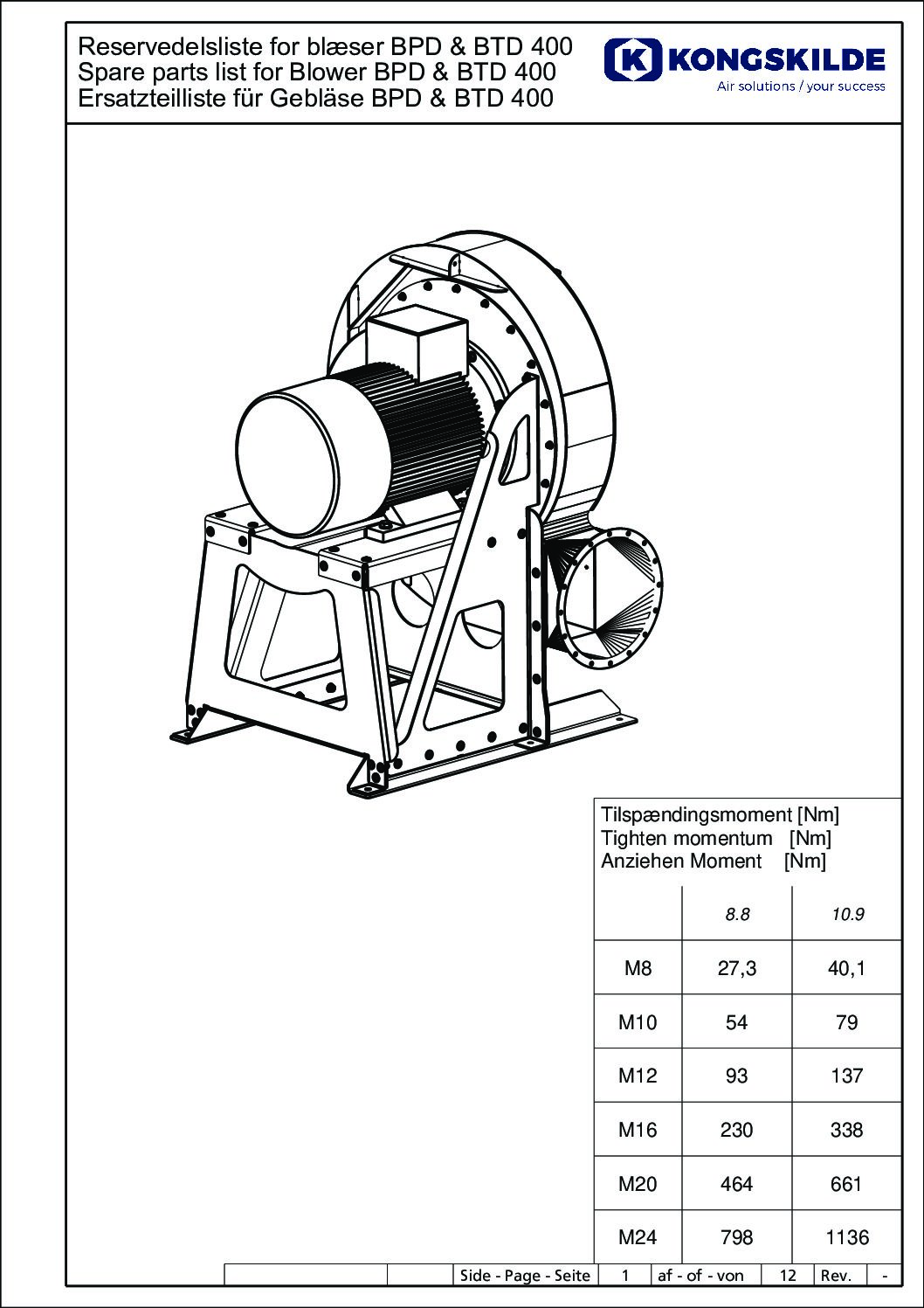

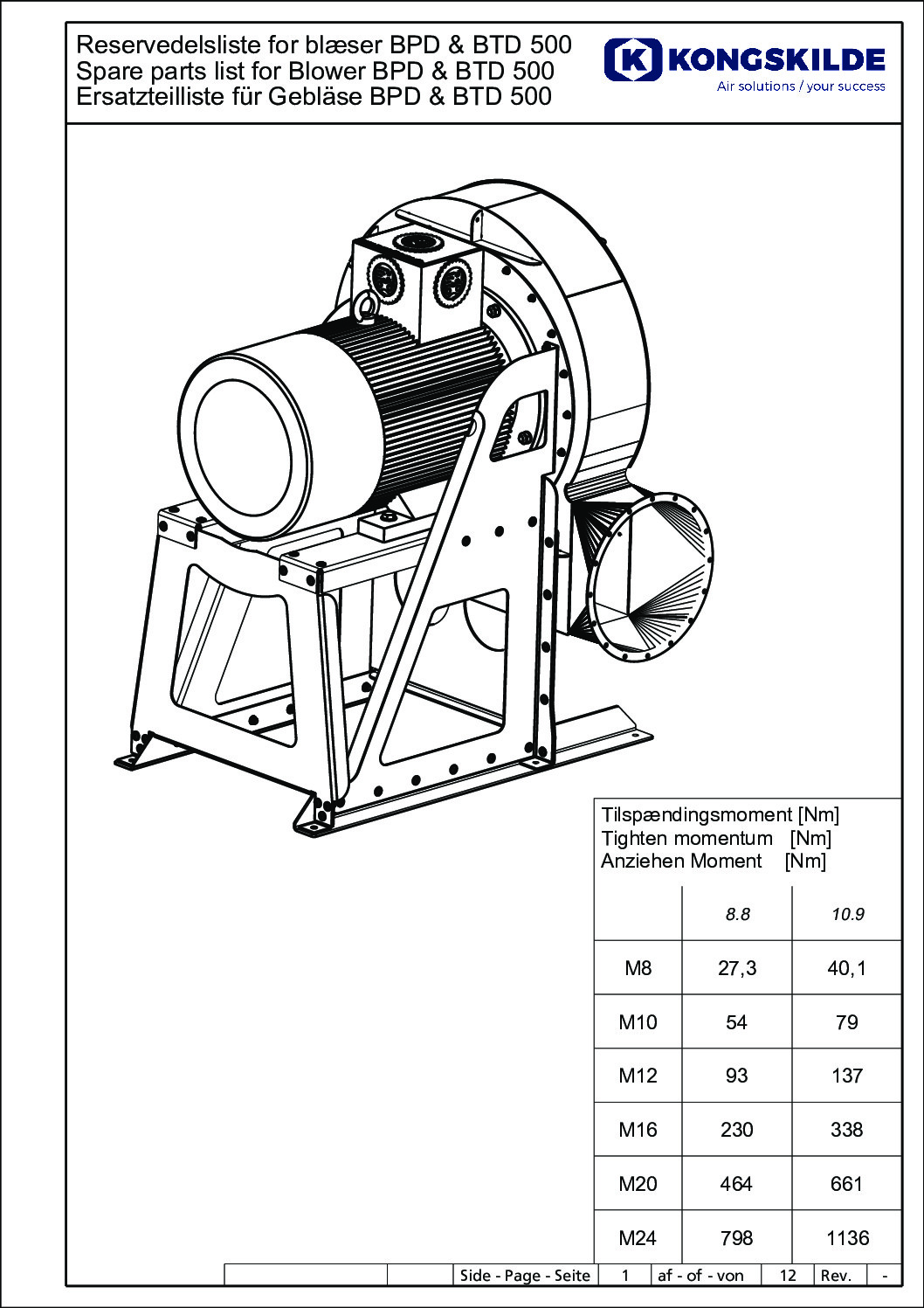

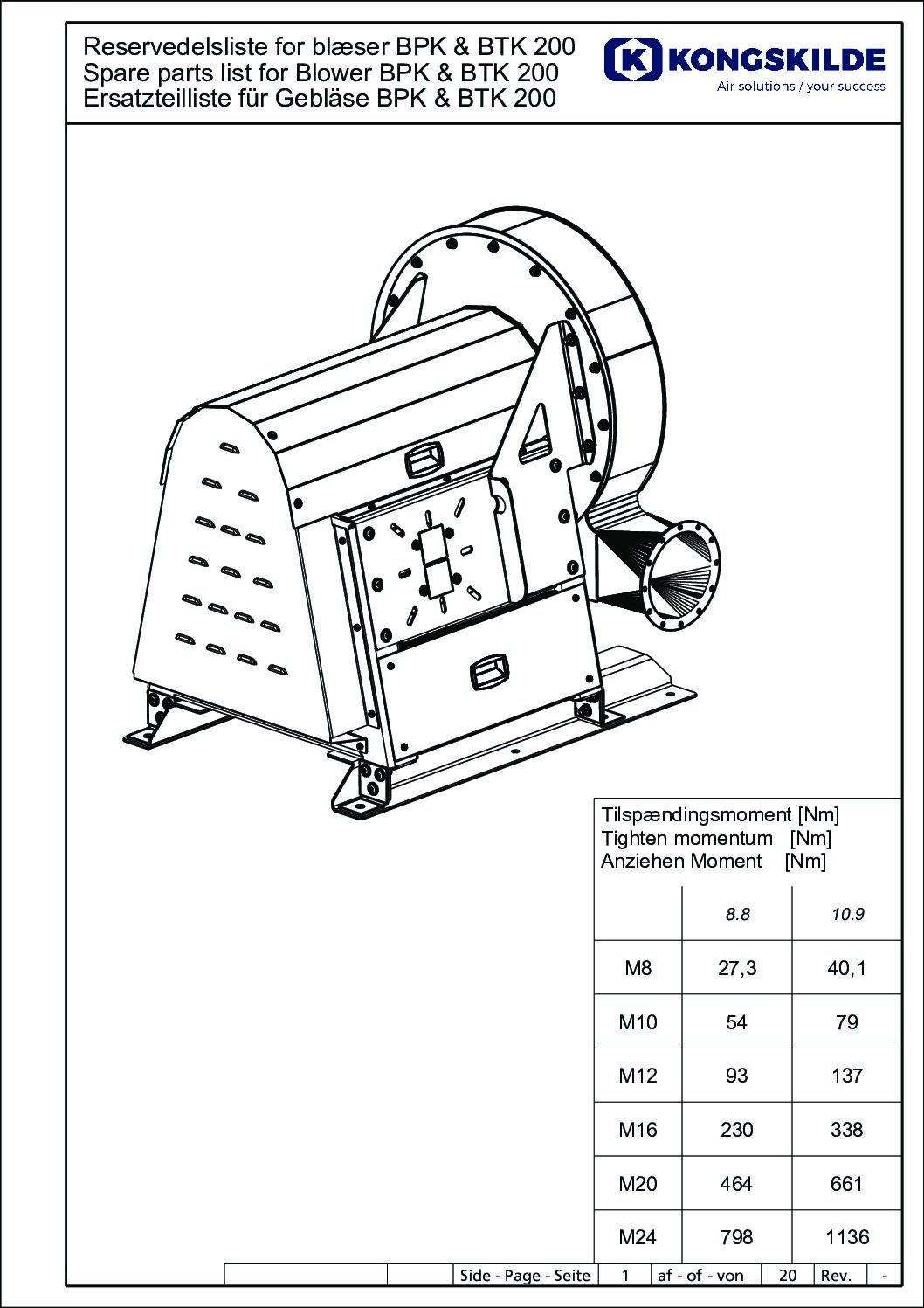

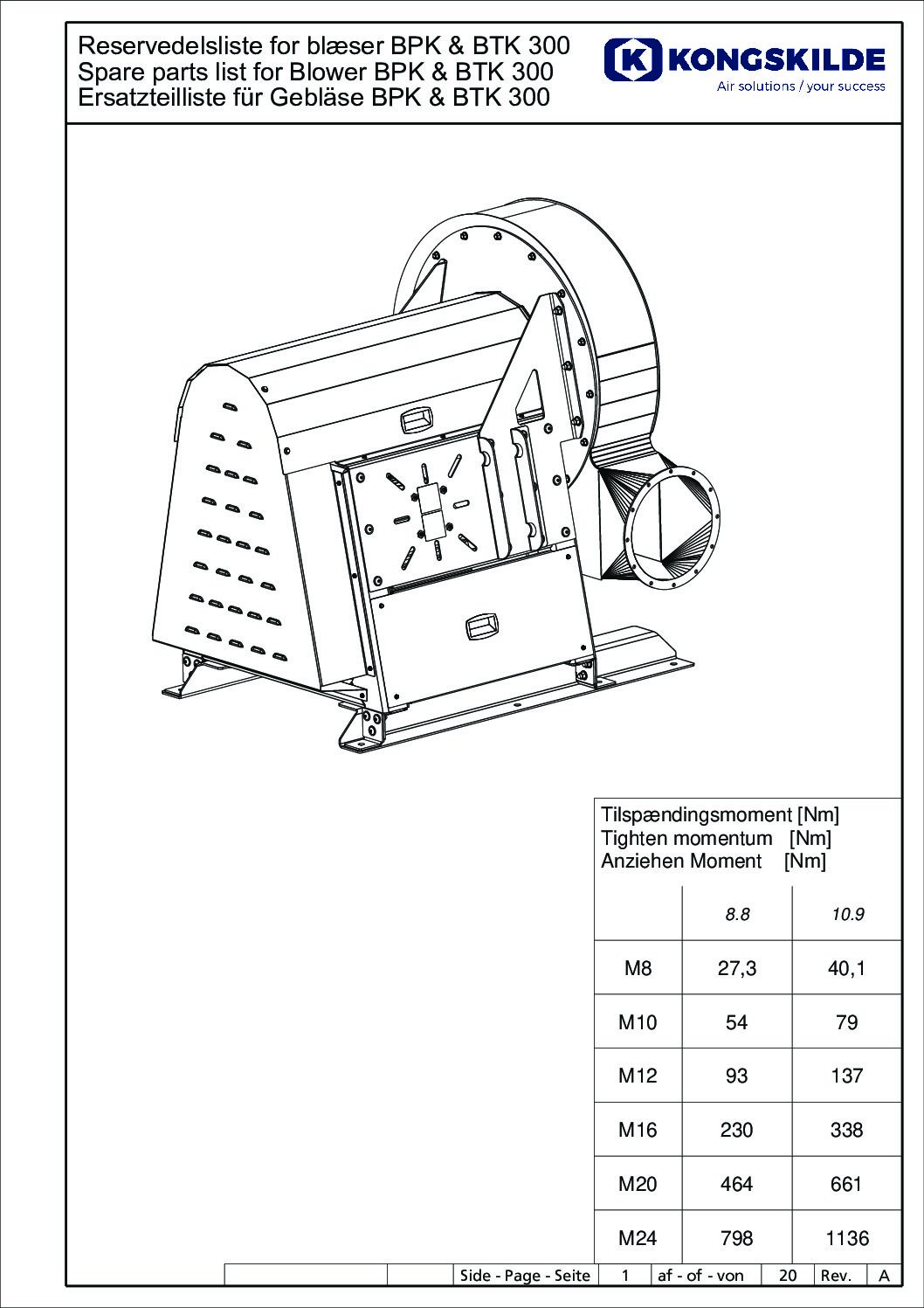

BTD / BTK & BPD / BPK Blowers

Directly and indirectly coupled centrifugal units for the handling of material through the blower

Kongskilde’s BTD, BTK, BPD, and BPK conveying blowers are high-performance centrifugal units designed for efficient material transport and ventilation in various industrial and agricultural applications.

Available in both directly coupled (BTD and BPD) and indirectly coupled (BTK and BPK) configurations, these blowers provide flexibility and durability for demanding conveying systems. Equipped with self-cleaning rotors and backward-curved blades, Kongskilde conveying blowers support air volumes from 800 m³ to 37,000 m³ and pressures up to 1170 mm WG, enabling efficient and reliable material handling.

Key Features of BTD / BTK & BPD / BPK Conveying Blowers

Designed for robust performance, Kongskilde’s conveying blowers incorporate advanced engineering and customizable options to meet diverse conveying needs:

- Self-Cleaning Rotor Design: Backward-curved blades prevent material build-up, ensuring smooth and consistent airflow while reducing maintenance.

- Direct and Indirect Coupling: Choose from directly coupled (BTD, BPD) or indirectly coupled (BTK, BPK) blowers to match specific performance requirements.

- Aerodynamic Intake: Enhances airflow efficiency, reducing energy consumption and optimizing blower performance.

- Flexible Air Volume and Pressure Range: Covers airflows from 800 m³ to 37,000 m³ and pressures up to 1170 mm WG, adaptable to a wide variety of applications.

- Multiple RPM Options: Available in configurations for both 50 Hz and 60 Hz, ensuring compatibility with diverse system requirements.

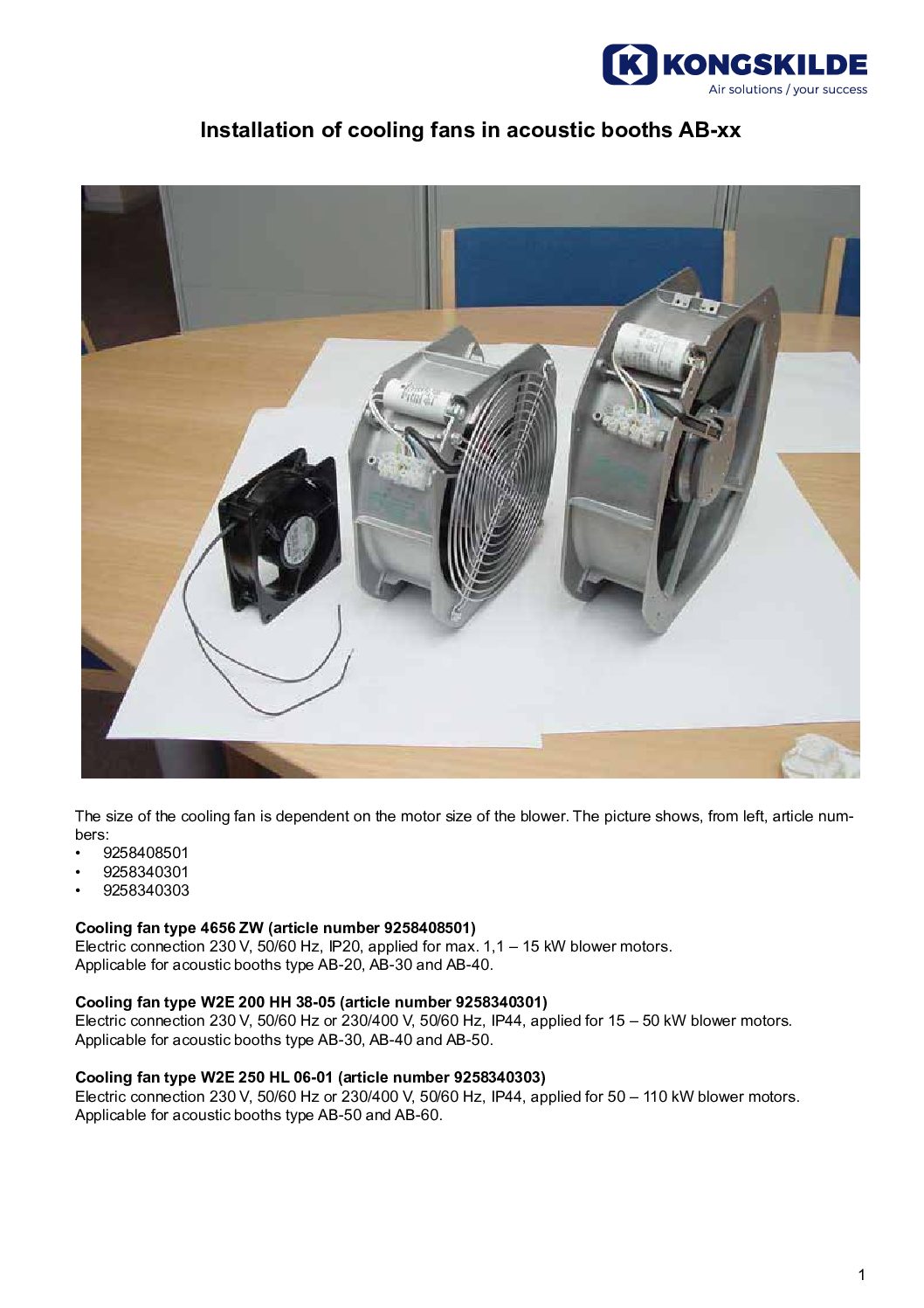

Sound Enclosures for Noise Reduction

For applications requiring noise control, the BTD/BTK & BPD/BPK blower series can be equipped with sound enclosures, significantly reducing noise levels. The enclosures are constructed from durable 1.25mm galvanized steel and insulated with fire-retardant, noise-absorbing material, and feature a cooling fan for reliable performance in demanding environments.

Benefits of Using Kongskilde Conveying Blowers

Kongskilde’s conveying blowers deliver key operational advantages that support efficient material handling and improved system performance:

- Optimized Efficiency: The self-cleaning rotor and aerodynamic intake maintain consistent airflow, minimizing downtime and maximizing throughput.

- Noise Reduction Options: With optional sound enclosures, these blowers operate quietly, improving workplace conditions and making them suitable for noise-sensitive environments.

- Enhanced Material Handling: These units are capable of transporting materials directly through the blower, simplifying material flow in pneumatic systems.

- Durable Construction: Made from 1.25mm galvanized steel with fire-retardant, noise-absorbing insulation, these blowers are built for reliable operation in industrial environments.

- Flexible Setup: Offering multiple RPM and mounting options, the BTD/BTK and BPD/BPK blowers are versatile and adaptable to different conveying systems.

Applications of BTD / BTK & BPD / BPK Conveying Blowers

- Pneumatic Material Conveying: Ideal for moving granular and free-flowing materials efficiently through pneumatic systems.

- Industrial Ventilation: Provides effective air circulation for ventilation in warehouses, production facilities, and other industrial spaces.

- Dust and Fines Removal: Can be integrated into dedusting systems to separate dust and fines from regrind materials or other granular products.

- Noise-Sensitive Environments: Optional sound enclosures allow for efficient operation in areas where noise control is important.

Downloads

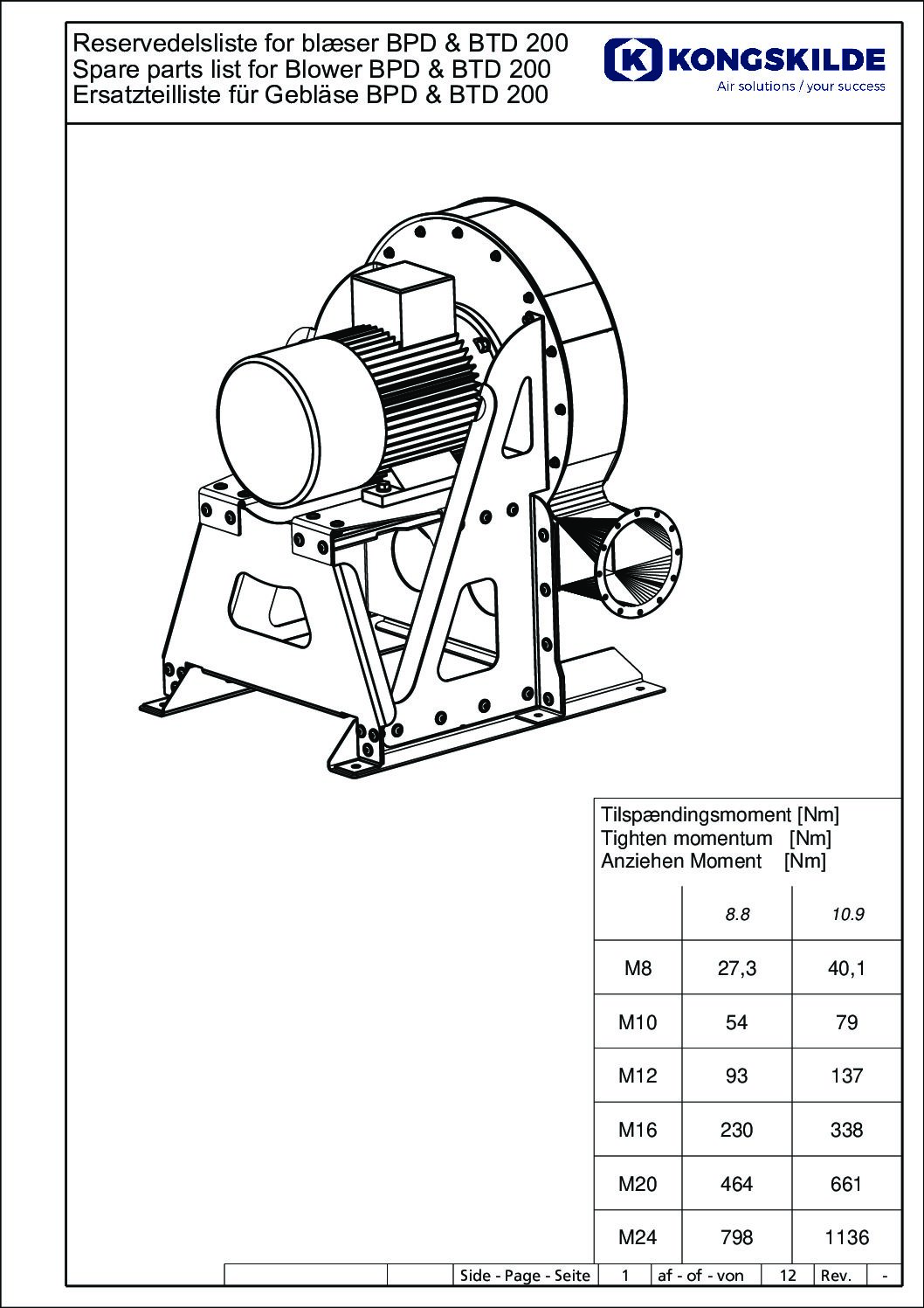

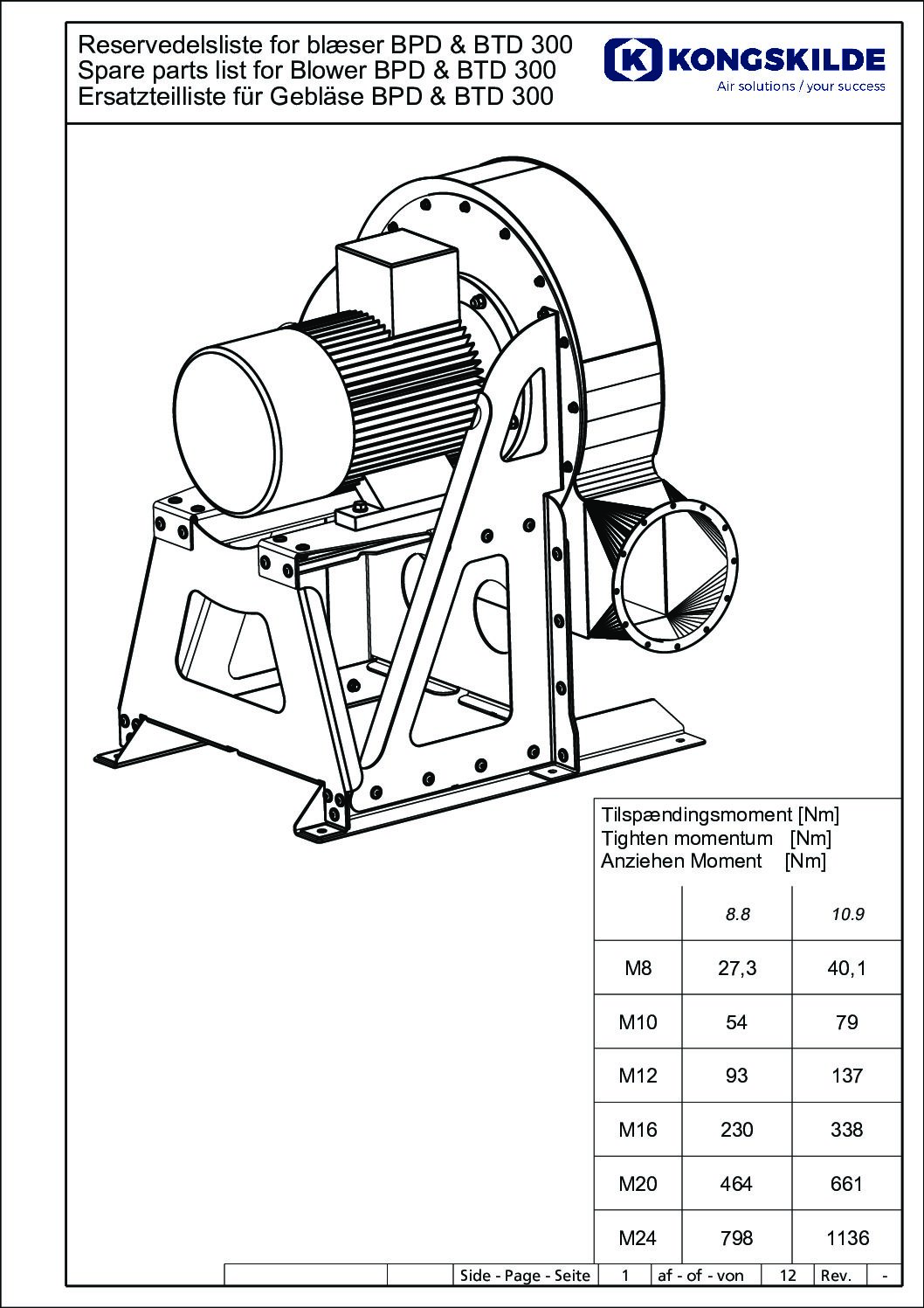

Download manuals, data sheets, and spare parts lists for the BTD / BTK & BPD / BPK blowers. For wiring diagrams, please contact us.

Data Sheets and Manuals

Spare Parts

BTD / BTK & BPD / BPK Applications

Kongskilde’s conveying blowers are versatile and well-suited for a variety of industrial applications.