The Challenge

This Polish producer of apple juice is a well-known brand in Central Europe.

- The waste product, apple pomace, must be removed when it has been dried, quickly and energy efficient.

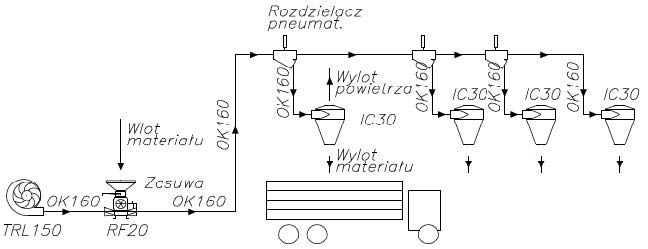

- The customer wanted a conveying system that could handle the transportation of apple pomace with a diameter of 10-15 mm from drying facilities to pending trucks.

The Solution

- The Kongskilde solution consisted of a TRL 100 blower with RF40 Rotary Valves. This system secures a dynamic form of transport of the material that obtains an adequate material yield with the use of the TRL 100 blower as well as a vigorous discharge of the pomace directly in the lorries.

The Advantages

- The transport of fragile materials like apple pomace is now fast and cost-effective with a smaller power consumption related to the pneumatic solution.

- The closed pickup system generates less dust in the factory and improves the working environment Less dust means lesser liability to slippery floors, reducing the need for cleaning and in the end, less maintenance in and around the transport system which saves money and increases productivity.

- Pneumatic conveying is faster and safer than previous transport with a tractor loader.