The Challenge

The factory located in Poland is a well know Polish producer of aluminum packaging and plastic foil packaging for wrapping yogurt and other kinds of foods.

- The conveying solution had to be able to deliver an adequate vacuum suction in gentle transportation of the aluminum and plastic skeleton from the production machines to the briquette machine without generating dust during the conveying.

- The amount of dust in the production facilities must be reduced to keep maintenance costs low to ensure a safe and healthy working environment and secure a final product without any trace of dust.

- The solution should provide clean air and operate without generating under or overpressure in the factory.

- The air had to be reused and headed back into the production area to save money on heating.

The Facts

- Material: Aluminum foil and plastic foil

- Number of machines: 11

- Suction points: 11

- Power consumption: 140 kW (from 11 pickups)

- Air amount: 18.000 m3/h (from 11 pickups)

- Pressure: 4.800 Pa/in 160 mm pipes

- Material thickness: Up to 200 microns

- System specifications: Conveying distance: 120 m

The Solution

- The pneumatic conveying reduces dust in the factory by transporting the skeleton material in pipes. By installing filters at the end of the line, the system also delivers needed clean air back to the production area.

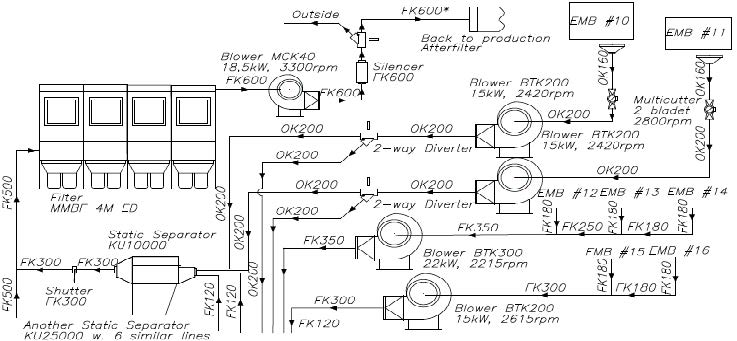

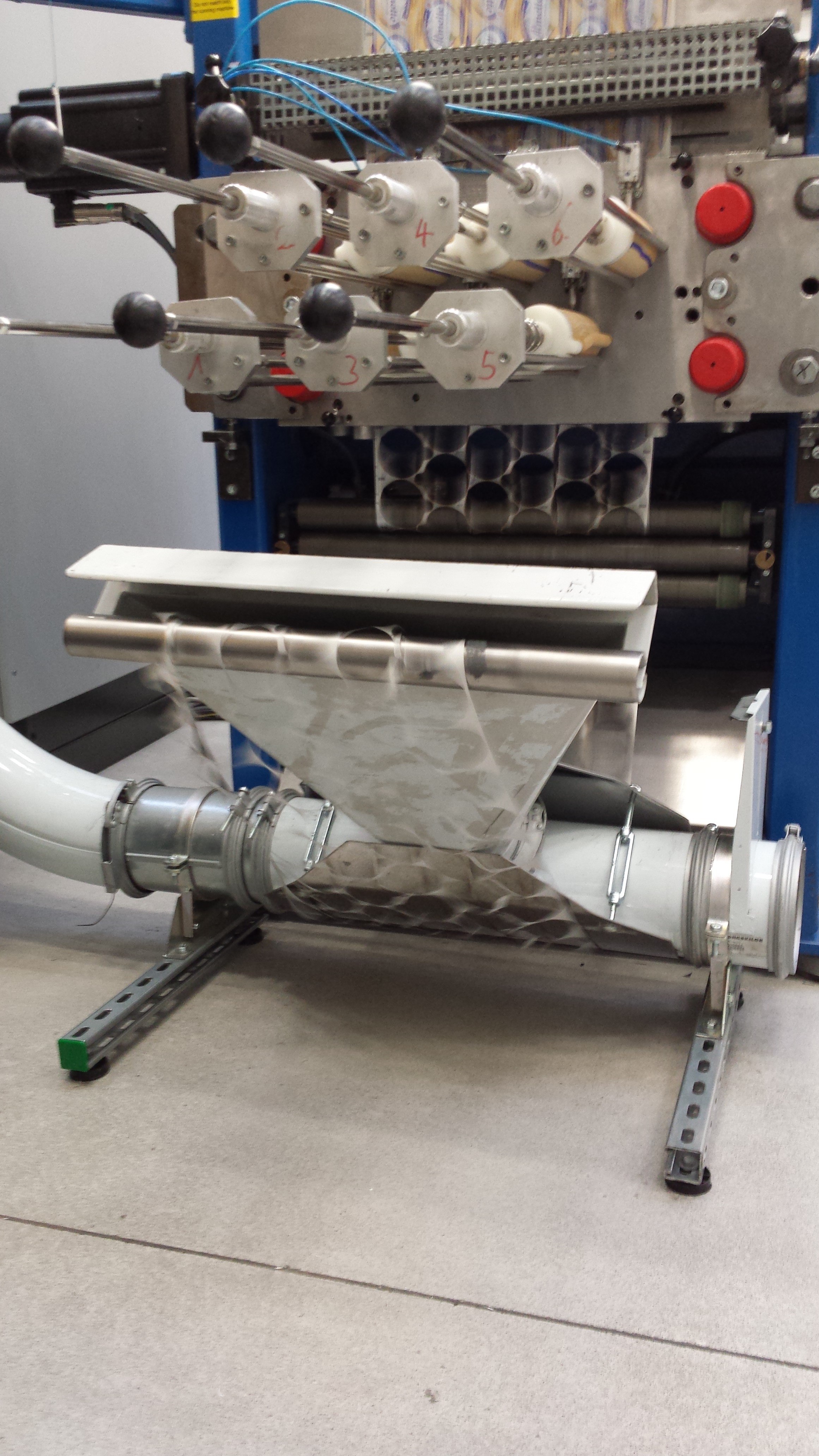

- The Kongskilde solution consists of a fishtail Collector, MultiCutters, blowers, static separators, MMBF bag filter combined with OK and FK pipes that ensured higher productivity.

- The system with the vacuum blower generates a fast and powerful conveying of the skeleton material from the production lines through the MultiCutter to the static separator and the briquette machine at the end of the line.

The Advantages and Benefits

- With less dust in the factory, the company minimizes the liability of slippery floors, reduces the need for cleaning, experiences less sick leave, and secures a final product without any trace of dust.

- The ability to generate a high vacuum effect combined with sufficient capacity of blowing and transporting the aluminum and plastic skeleton without damaging the material contributes to increased productivity.

- The noise reduction is of significant importance for the health of the staff working by the conveying lines.

- The solution creates no overpressure when discharged, and no underpressure in the production area as the air used to convey is filtered and returned to the factory.

- The pipes mounted in the ceiling save space on the floor.