Streamline Injection Moulding Conveyors with Air-Powered Transport

For over 75 years, Kongskilde has delivered innovative solutions that make material handling simpler and more efficient. Our pneumatic conveying systems are ideal for transporting plastic components and injection moulded parts across production environments with minimal operator involvement.

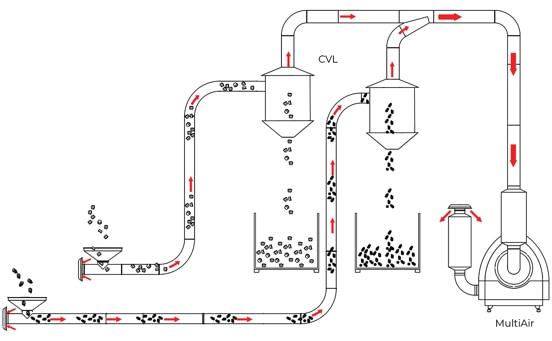

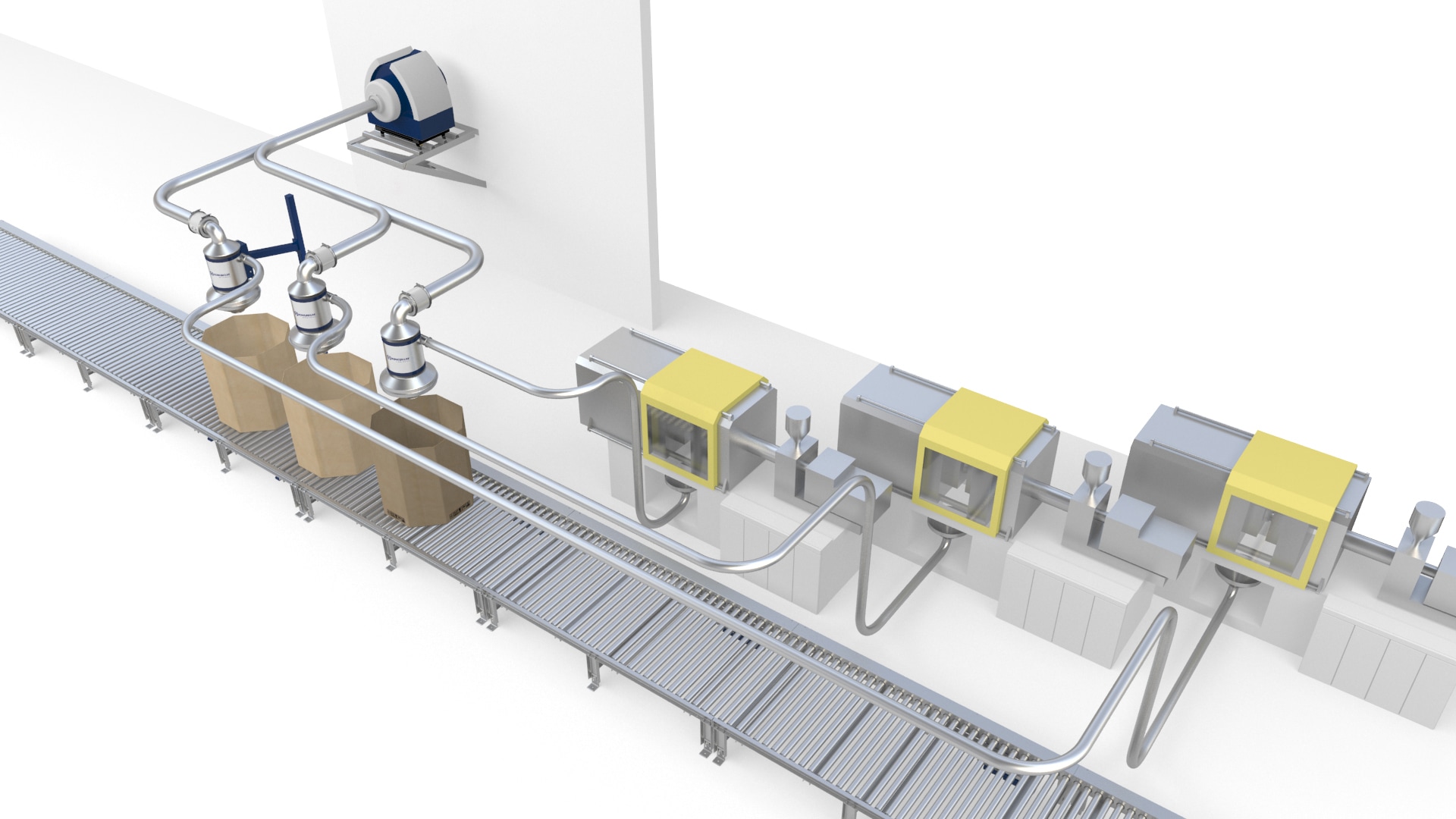

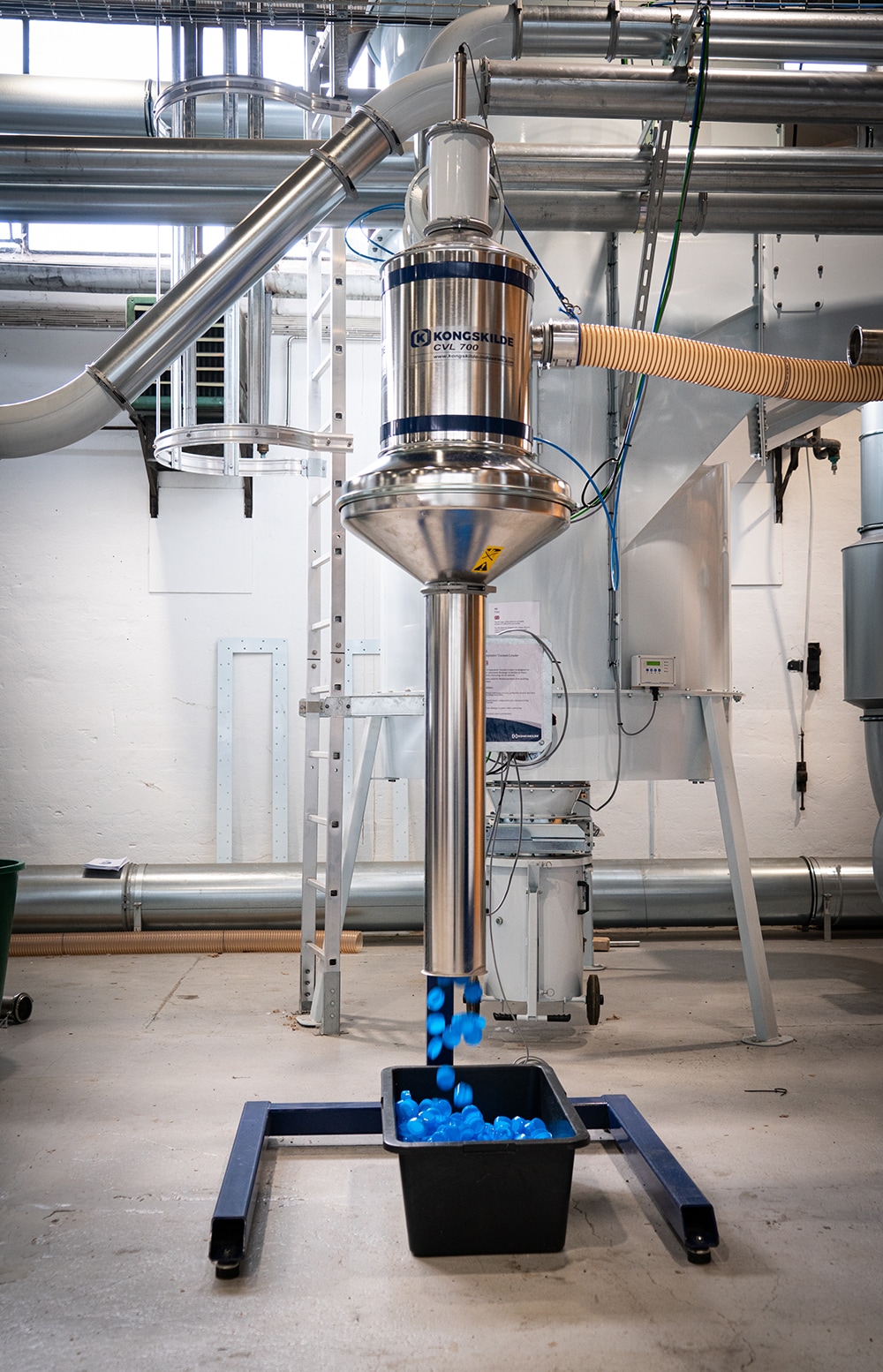

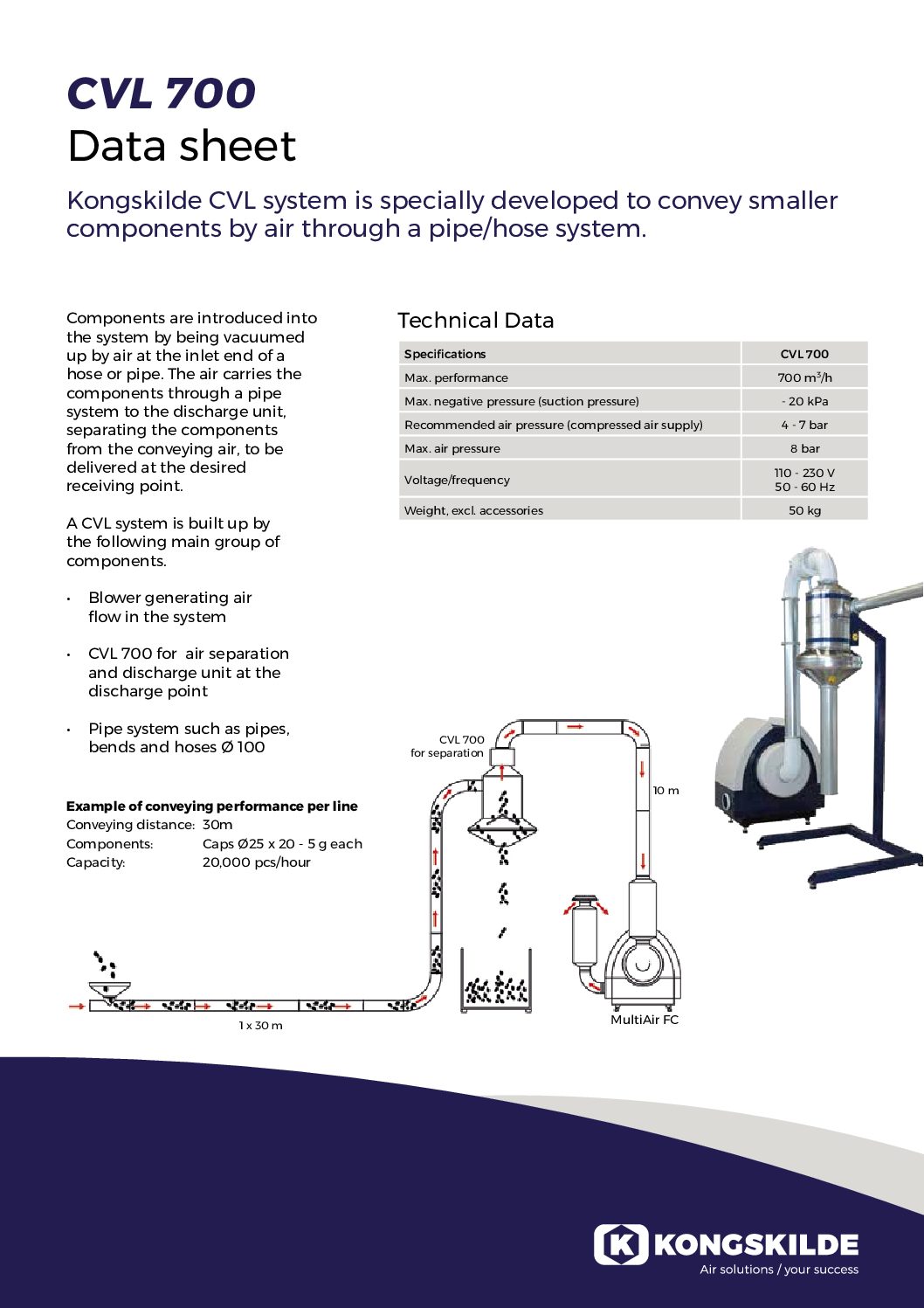

Using vacuum-powered inlets, our systems gently lift parts into a closed pipe network. The airflow moves them swiftly to a discharge unit, which separates air from material and delivers it to its final destination—whether that’s a storage bin, packaging line, or another processing step.

Modular Pneumatic Conveying Components for Flexible System Design

For over 75 years, Kongskilde has delivered innovative solutions that make material handling simpler and more efficient. Our pneumatic conveying systems are ideal for transporting plastic components and injection moulded parts across production environments with minimal operator involvement.

Using vacuum-powered inlets, our systems gently lift parts into a closed pipe network. The airflow moves them swiftly to a discharge unit, which separates air from material and delivers it to its final destination—whether that’s a storage bin, packaging line, or another processing step.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Pneumatic Conveying of Bottle Caps – Europe

The company requested a system that would cut away the logistics of having a forklift operator transport pallets back and forth to save time and increase safety.