Reduce Labor and Noise with Efficient Trim Extraction

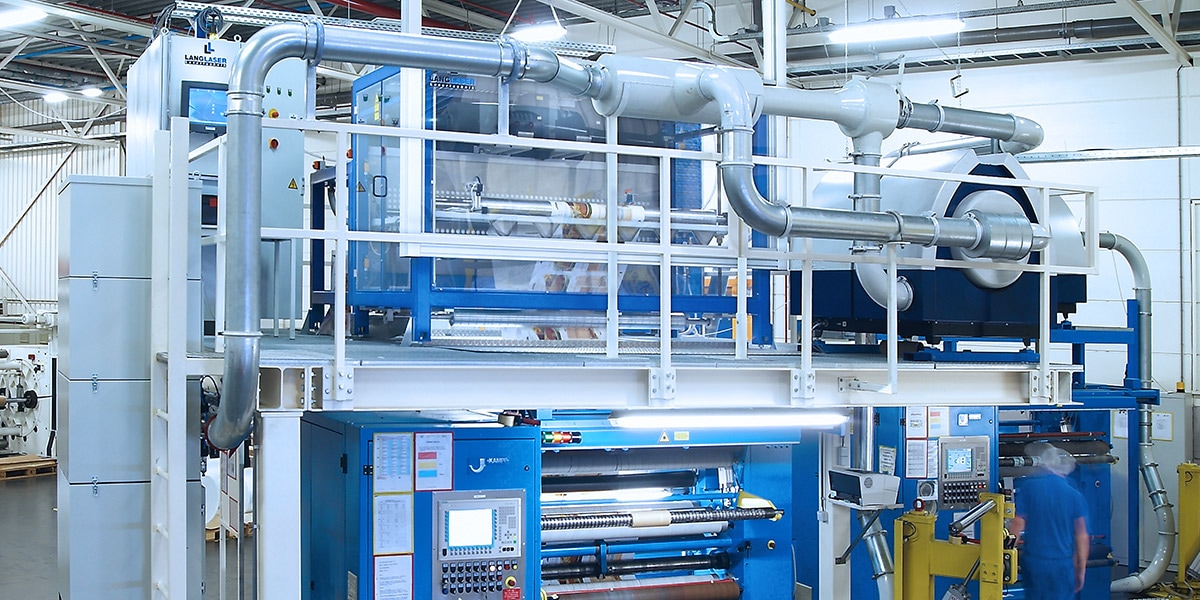

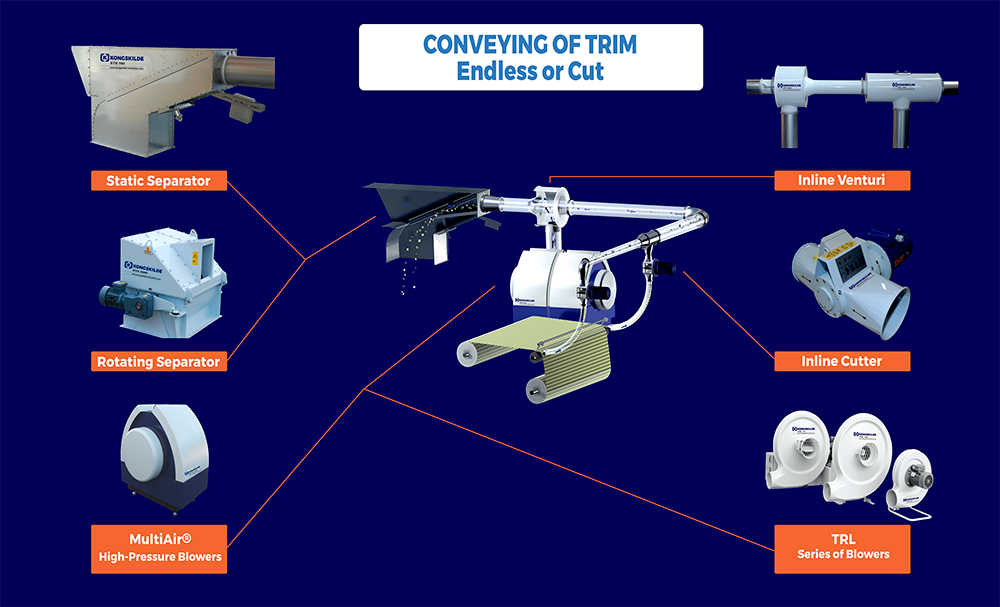

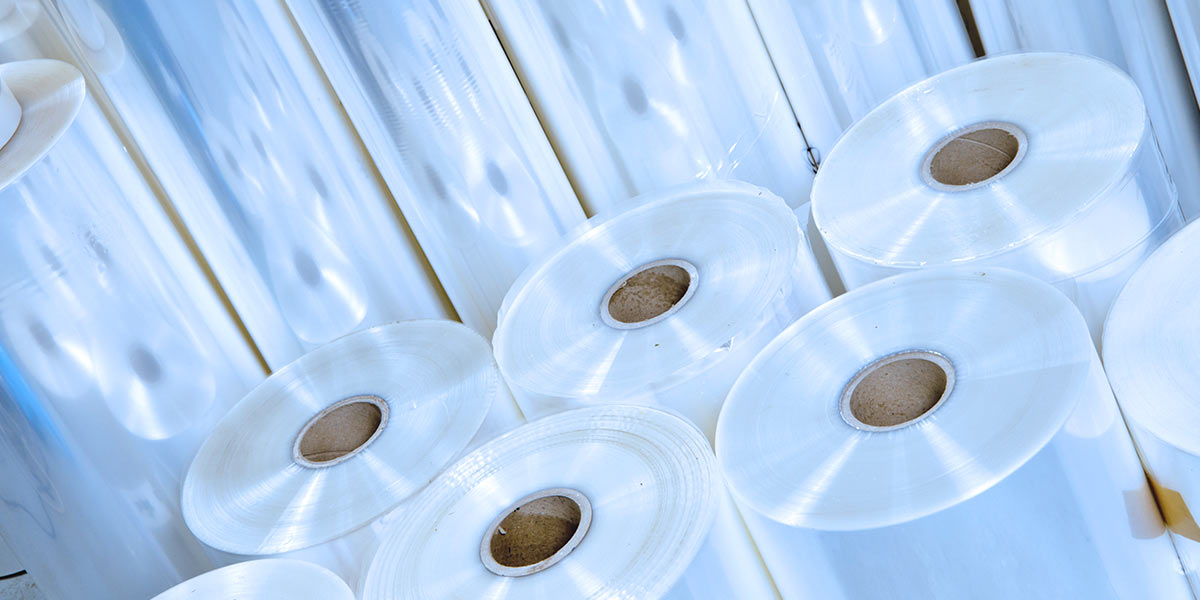

Kongskilde’s trim handling systems are engineered for efficient pneumatic extraction of continuous trim in film & foil converting, paper manufacturing, and packaging applications. These systems are designed to keep pace with modern converting and production machines such as cast lines, slitters, and rewinders.

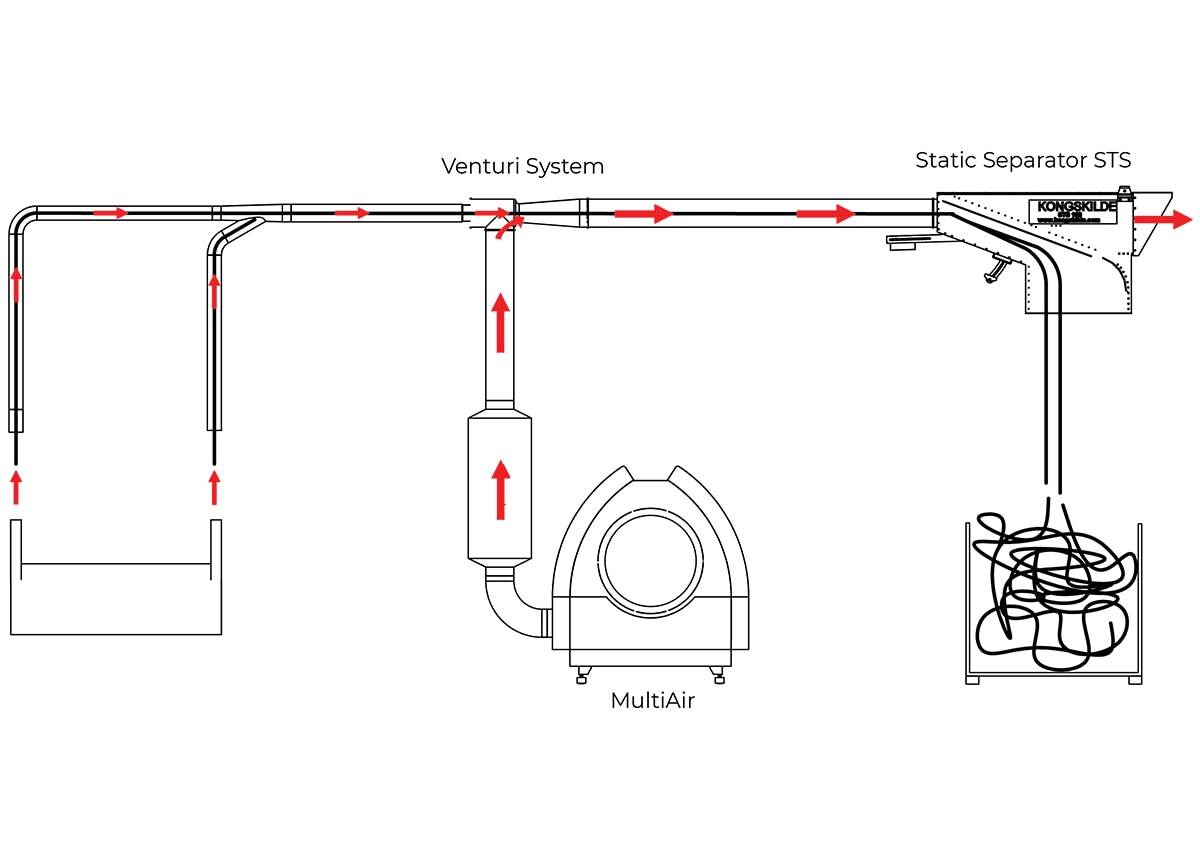

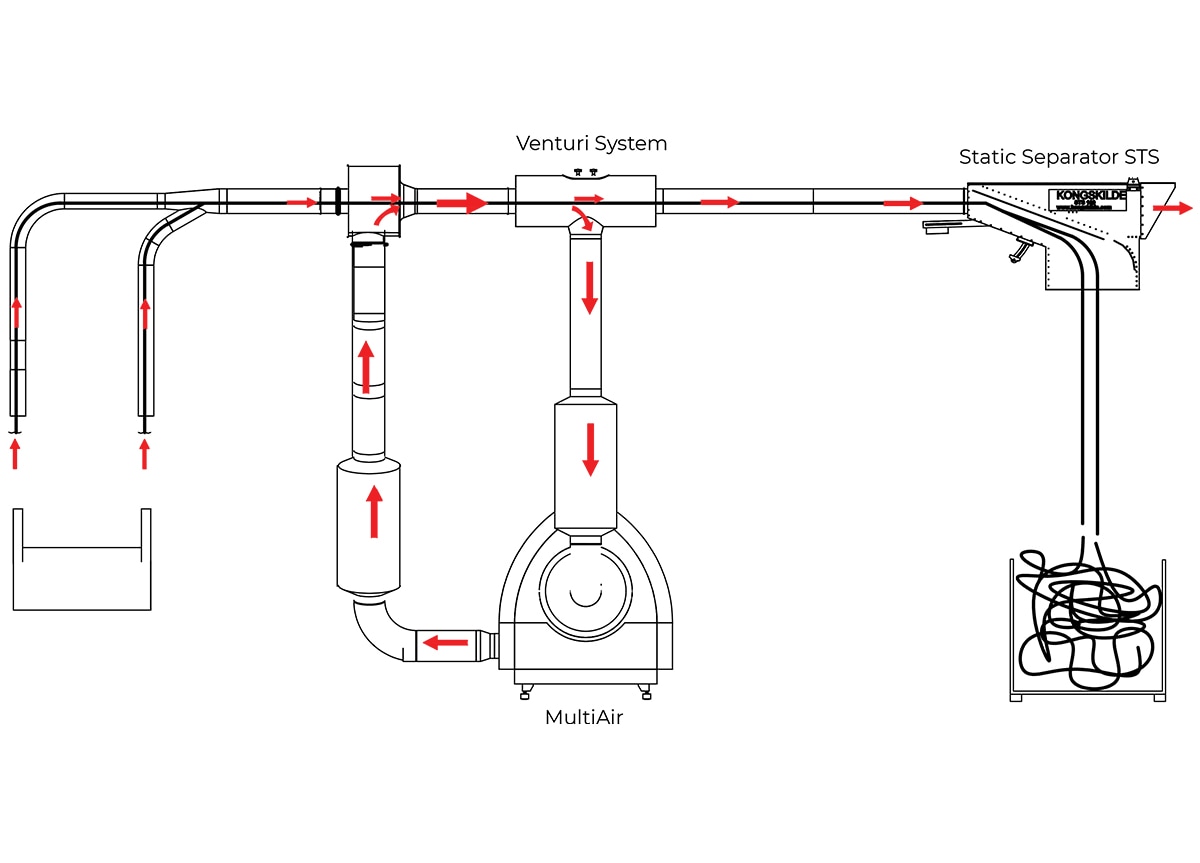

Our versatile Venturi systems (ITF and KIV), paired with the high-performance MultiAir® blower, offer a cost-effective solution for conveying endless trim. These systems reduce labor demands and maintenance costs, while also minimizing noise—making them suitable for installation directly within the production environment.

Whether you’re handling edge trims from foil, film, or paper, Kongskilde systems streamline operations and help keep your facility clean and efficient. The same system architecture also supports waste paper extraction systems, delivering flexibility for a wide range of material handling needs.

Videos of Endless Trim Conveying

Kongskilde’s pneumatic waste extraction systems efficiently manage edge trim from film & foil converting lines and paper production equipment.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Process Waste Handling of Endless Trims – Lollypops – Spain

Worldwide confectionary producer needed a solution that would reduce manual labour, increase productivity, and improve the work environment.