Downsizing Cutters & Granulators

MultiCutter MCB

Innovative inline cutting unit designed to efficiently process continuous and endless waste materials into small pieces.

Our cutting-edge units seamlessly integrate into both new and pre-existing waste extraction systems, ensuring optimal performance and waste management solutions for various industries.

The MCB MultiCutter efficiently processes materials such as paper, cardboard, flexible plastics, and aluminum foil, making it ideal for industries like packaging, label production, and printing that need effective waste management solutions to enhance operational efficiency and sustainability.

Versatile Waste Handling

MCB cutters are unique inline cutters designed to seamlessly integrate into existing waste extraction systems. They offer solutions for numerous applications, efficiently cutting a wide variety of materials with minimal air resistance, high throughput rates, and exceptional reliability.

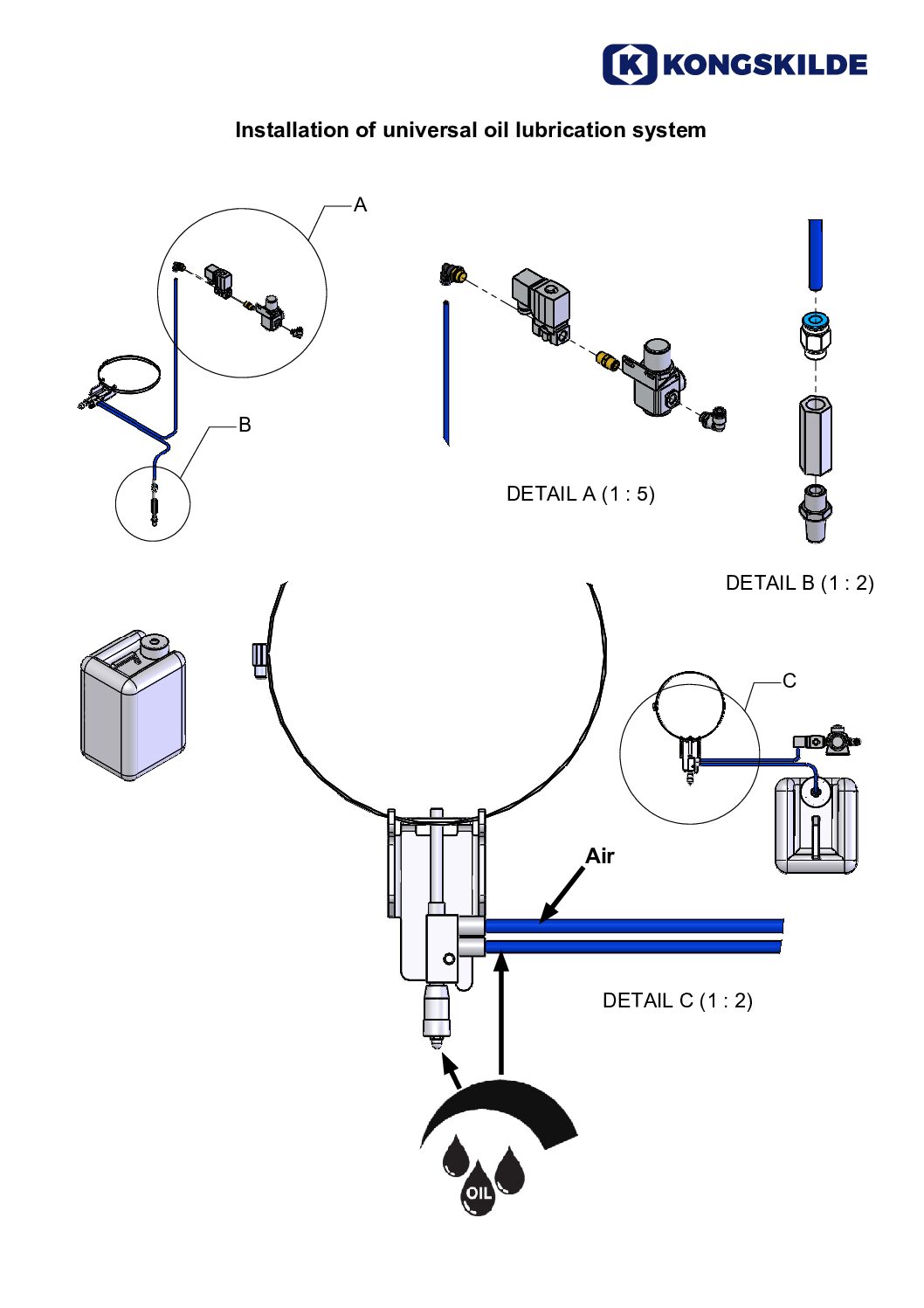

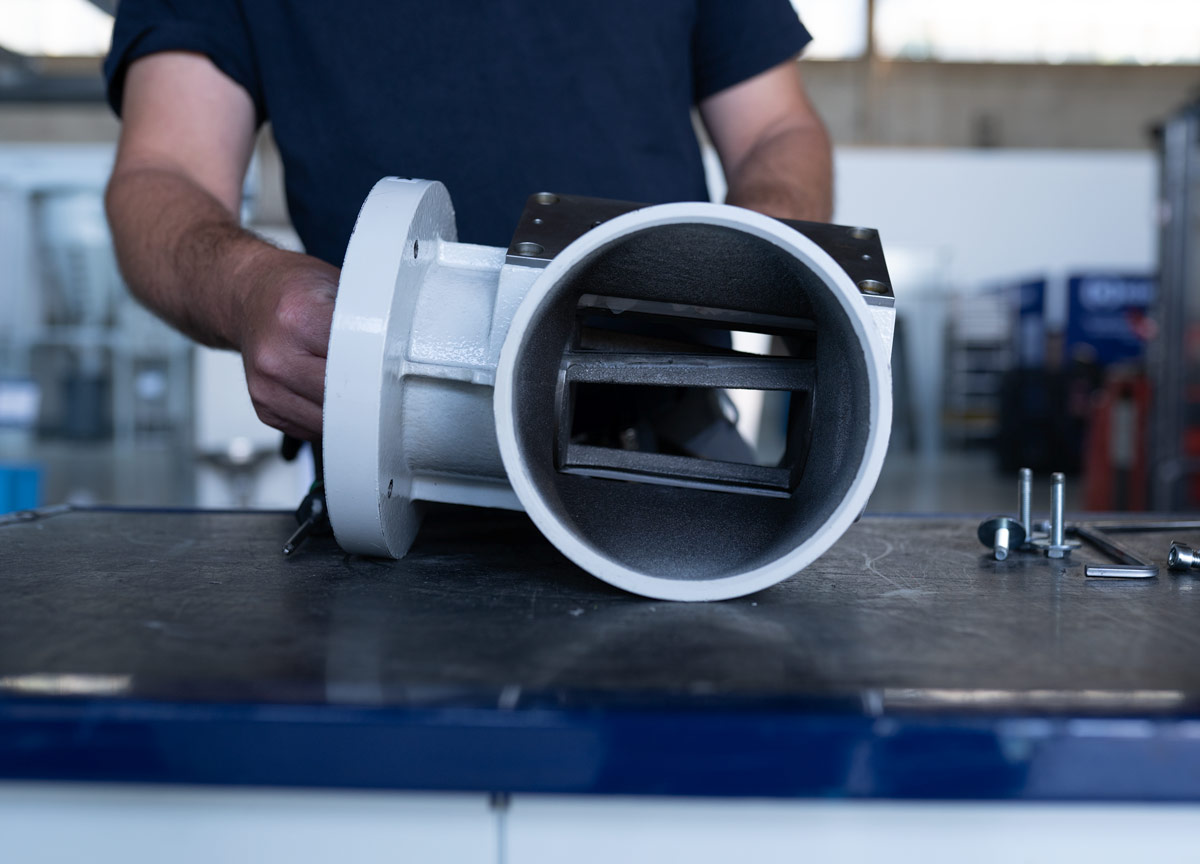

The MCB 100, 160, 180, and 200 cutters are specifically engineered for cutting production waste. The inline cutter is equipped with 2 or 3 rotating knives, and a fixed blade. These versatile units can handle various residual materials from production processes, such as edge strips and stamped grids, within pipe systems.

Materials that can be cut include:

- Self-adhesive materials including labels

- Various types of cardboard

- Packaging materials

- Wood veneers

- Synthetic materials (plastics)

- Paper

- Textiles

- Foils

- Additional materials upon request

Benefits

- High Reduction of Waste Volume: Effectively decreases the volume of production waste

- Versatile Cutting Capability: Capable of cutting a wide range of materials.

- Compact Design: Optimized for space-saving installation.

- Genuine Scissor-Knife Cut: Ensures precise and clean cuts, while minimizing dust.

- Low Noise: Scissor cut principle assures low noise during operation.

- High Throughput: Maintains high processing speeds.

- Low Energy Consumption: Energy-efficient operation.

- Low Air Resistance: Minimizes impact on airflow within extraction systems.

- Low Operation Costs: Cost-effective maintenance and operation.

- Flexible Placement: Cutter can be mounted in any direction.

Cutter Maintenance & Service

We provide maintenance support and original spare parts to keep your cutter running reliably.

Downloads

Download available brochures and data sheets.

MCB MultiCutter Model Comparison

Compare available MCB MultiCutter models. Visit the downloads section for more information on specific models.

| Inlet & Outlet | Weight incl. motor (kg) | Power (kW) (50Hz / 60Hz) | Knives | RPM (50Hz / 60Hz) | |

|---|---|---|---|---|---|

| MCB-100 | 100mm | 22 | 0.55 / 0.66 | 2 | 1500-3000 / 1800-3300 |

| MCB-160 | 160mm | 34 | 0.75 / 0.9 | 2 or 3 | 1500-3000 / 1800-3300 |

| MCB-180 | 160mm | 65 | 1.5 / 1.8 | 2 or 3 | 1500-3000 / 1800-3300 |

| MCB-200 | 200mm | 80 | 1.5 / 1.8 | 2 or 3 | 1500 / 1800 |