The Challenge

- A factory located in Poland is a well-known producer of different kinds of books for the domestic and international markets

- The client has five production lines. Trimmings are generated on machines of the three-side trimmer type; a “woolly” paper dust is generated by the cutter machine

- However, the old system was inefficient, outdated, and based on cyclones and worn-out fans

- The extraction operation was causing downtimes and a mess during the production process, and prevented the connection of another production line

- Trimmings were lying all around the machine and in waste containers. This did not look good when the client received visitors

- The waste that accumulated around individual machines had an adverse impact on productivity

- The company needed a solution for the extraction of trimmings in order to ensure cleanliness in the production area, and increase productivity while keeping downtime to a minimum

The Solution

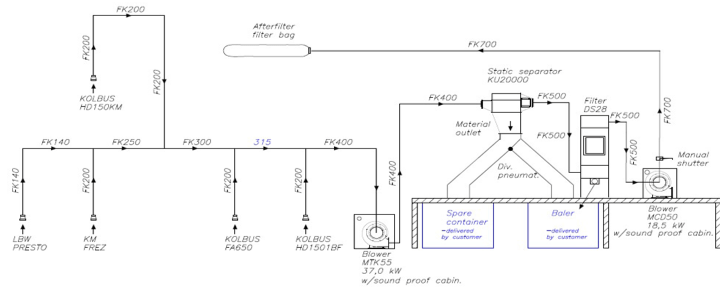

- The Kongskilde solution includes: Piping, a main fan (MTK 55), a static separator (KU 20000), a cartridge filter (DS 28), an additional fan (MCD 50), and the control panel controlling the entire system intuitively and automatically

- Large elements (the filter and separator with the divider) are supported by the frame, so that the trim extraction takes up relatively little space, allowing the trucks to maneuver and pick up waste containers

- The system can automatically switch the waste to the second container/press when the first one becomes full

- Discharge of unwanted dust is done through the use of a lock situated under the filter and connected directly to the press

The Advantages and Benefits

- The solution features a modular design and high flexibility with fast adjustment of the pneumatic conveyor that meets even special requirements such as fire protection, and a clean air filter

- The system ensures fast and gentle transport of material and guarantees high productivity without generating dust in the production facility, as well as cost-effective waste disposal

- More space around the machines ensures higher productivity

- The return of clean air to the hall reduces heating costs in winter

- Labour costs associated with the manual handling of waste in production areas are no longer an issue

The Facts

- Material: Paper

- Width of trim: Up to 30 mm

- Length of trim: Up to 430 mm

- Thickness of trim: Up to 400 g/m2, max. 80 mm

- Number of machines: 5

- Suction points: 1 per machine

- Speed: up to 9,000 cuts/hr.

- System specifications: Height 60 m, Width: 3.5 m, 5 angle joints