Inline Feeders

KIV System

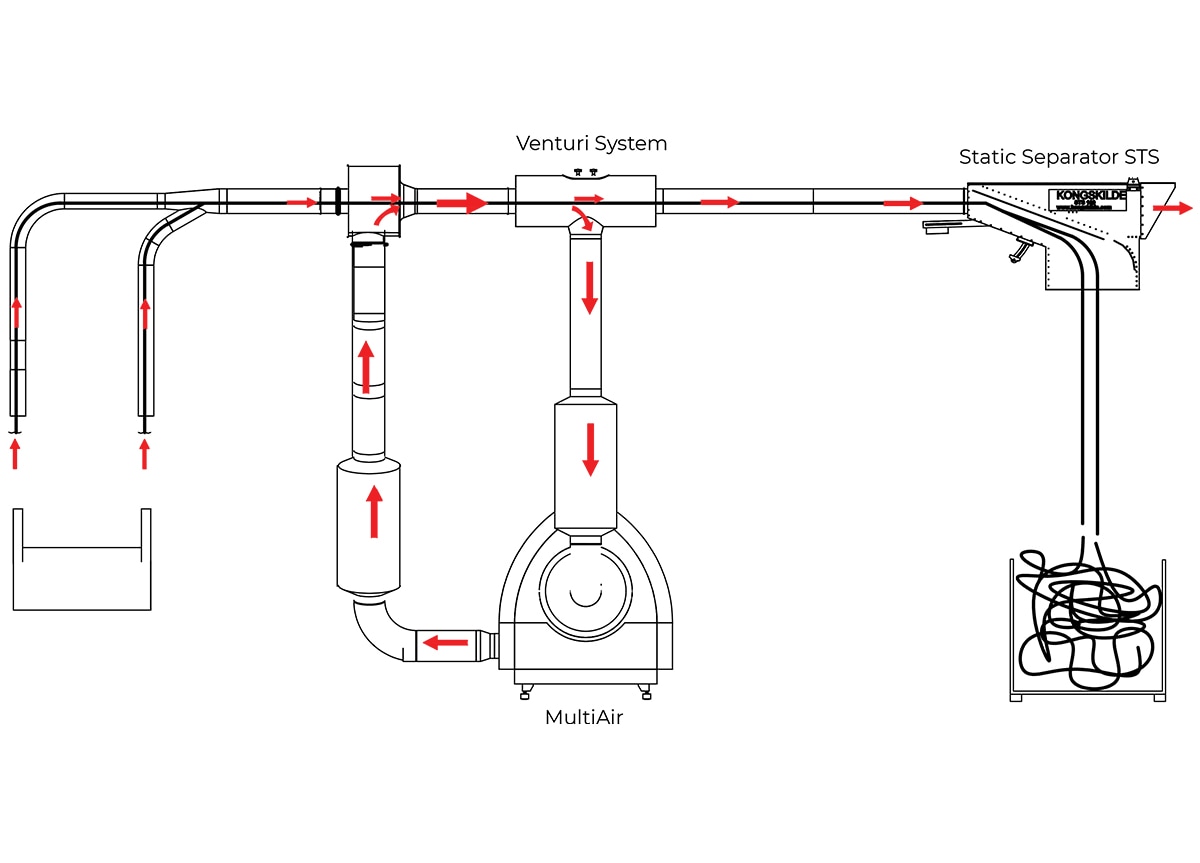

The KIV is paired with the ITF venturi to improve suction and airflow in a conveying system

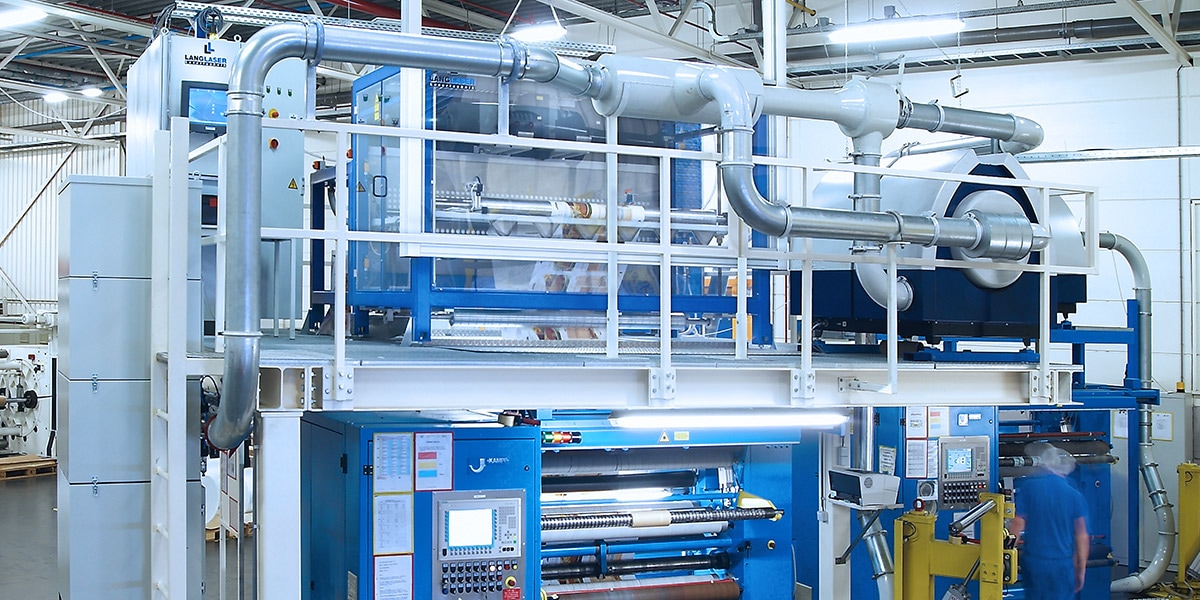

The Kongskilde Inline Venturi (KIV) System enhances the efficiency of pneumatic conveying systems by improving suction and airflow. Designed for use with the ITF Venturi, the KIV air return unit allows the system to return induction air back to the blower, ensuring that only the conveyed materials and induced air pass through the inline venturi.

This system is particularly effective for transporting continuous edge trim, off-cuts, and irregularly shaped components over long distances without the material coming into contact with any moving parts.

Kongskilde Inline Venturi (KIV) System

The KIV air return unit eliminates the need to increase pipe size to accommodate excess air volume generated by the venturi, making it a highly efficient solution for material conveying. By pairing the KIV system with an ITF venturi, manufacturers can:

- Ensure a seamless conveying process for off-cuts, rejects, tops, and tails.

- Optimize airflow for consistent and efficient material transport.

- Minimize air pressure loss while improving overall system performance.

Advantages of the Kongskilde Inline Venturi System

Unlike conventional venturi setups, the Kongskilde Inline Venturi system provides enhanced suction by allowing materials to enter the piping directly. This flexible placement of the ITF venturi and KIV air return system ensures that performance is not compromised, even when components are installed at different points in the conveying line.

Key Benefits

- Efficient Airflow Management – The pneumatic circuit operates in a closed-loop system, recirculating induction air back to the blower to reduce energy consumption.

- Optimized Material Handling – Materials move gently through the system with no contact with moving parts, reducing the risk of damage.

- Flexible System Layout – The KIV inline venturi system can be installed in the most convenient location to fit your factory layout, minimizing space constraints.

- Low Maintenance Costs – With no moving parts in the material path, wear and tear are significantly reduced, leading to lower maintenance and operational costs.

Downloads

Download brochure, data sheet, and manual for the Kongskilde Inline Venturi (KIV).

Related Products

Videos

KIV System Applications

The KIV system efficiently handles edge trim, off-cuts, rejects, tops and tails, and odd-shaped components. Designed for maximum flexibility, reliability, and quality, it seamlessly integrates with Kongskilde’s portfolio of complementary products, enhancing customization for world-class pneumatic systems.