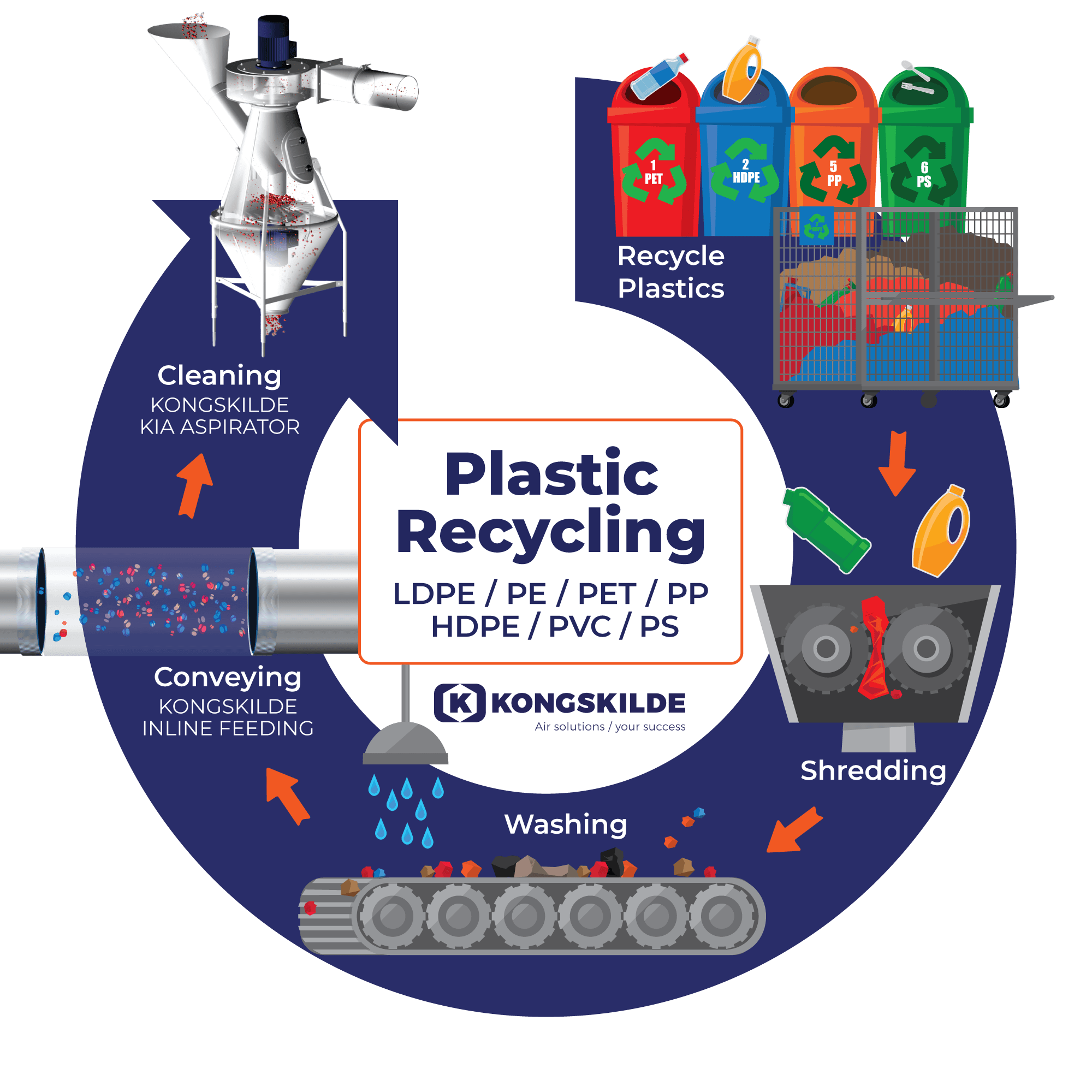

Dedusting and Separation Systems

Dedusting and separation systems can be added to the recycling process to improve the quality of recycled material and free the working environment from dust and impurities. For further information contact us or select your solution below.

We offer various dedusting systems to remove dust and contamination

Whether the case involves pellets or granulated regrind, dust and contamination can negatively affect the processing of materials and cause rejections in the manufacturing or recycling line. Kongskilde Industries offers various dedusting systems to remove these and other processing challenges, helping ensure cleaner, higher-quality output.

What is dedusting and separation?

Dedusting is the industrial cleaning of granulates, generally using some form of pneumatic separation system. A dedusting system typically removes dust from re-processed materials, and may also target the elimination of light impurities. At Kongskilde Industries, we offer innovative dedusting and separation systems, which can all be found on this page.

Why does dedusting and separation take place?

Dedusting and separation systems are designed to remove or reduce dust, fine particles, and other potential contaminants, or to separate dissimilar materials. This process improves the overall material quality and value, while also maximizing production efficiency. Dust is the most common fine impurity that attaches to pellets or granules; an effective dedusting system also minimizes the risk of dust being expelled into the workplace.

What materials are handled by these systems?

Common applications for dedusting systems include granulated and virgin materials such as rubber, PP, PET, PE, HDPE, Nylon, ABS, and carpet fibers. Recycled materials can become valuable reusable input after undergoing a dedusting and separation process. Material can also be evacuated from granulators, mixers, and other equipment using these systems—making dedusting a critical function in both recycling operations and production environments.

How many system options are there?

Various forms of dedusting and separation systems exist. For example, pneumatic separation solutions offer a gentle yet effective approach to the dedusting of pellets. Kongskilde’s AirWash system is a precise dedusting system that can convey and clean simultaneously. This is just one example—explore the full range of options available below.

What are these systems composed of?

A typical dedusting system includes components like aspirators, cyclones, and piping. Airflow is used to evacuate lightweight impurities into dust cyclones or filter socks, while clean, re-processed material is discharged through the bottom outlet of the aspirator. These systems are often integrated into broader material handling operations and can be installed or retrofitted into existing manufacturing or recycling setup.

Finding the right system for your manufacturing or recycling process

Having the right dedusting system in place will reduce rejection rates, improve product quality and process efficiency, and decrease maintenance and downtime. If materials are not properly dedusted, residual dust may clog filters and screens in downstream equipment—disrupting operations and reducing production performance.

Questions?

Get in touch with our world-class customer support and technical specialists.