Modular pneumatic solutions for the production of low-weight materials.

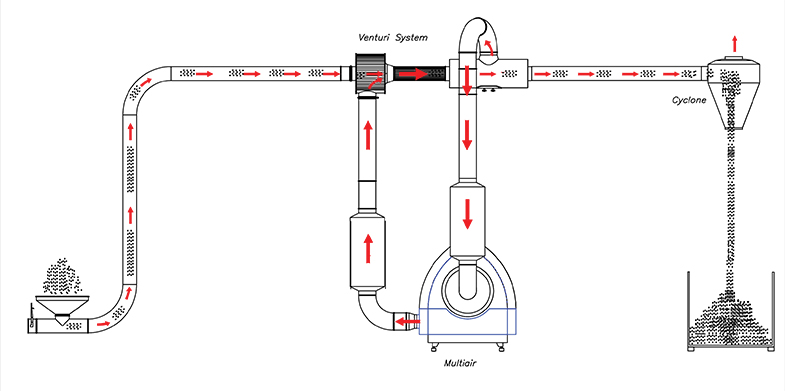

Suitable for both high and low-capacity installations, the conveying system is designed to convey granules with low specific weight, such as EPS and EPP, which do not float very easily and must be vacuumed into the conveying system.

The blower builds air pressure and the air passes through the KIV Venturi. This creates a vacuum on the material inlet side and pressure on the outlet side of the conveying line.

The unique air return system minimizes the amount of air released at the point of material discharge. Complete reliable systems can be made of standard components and installed anywhere.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.