Reliable Solutions for Off-Cut Conveying

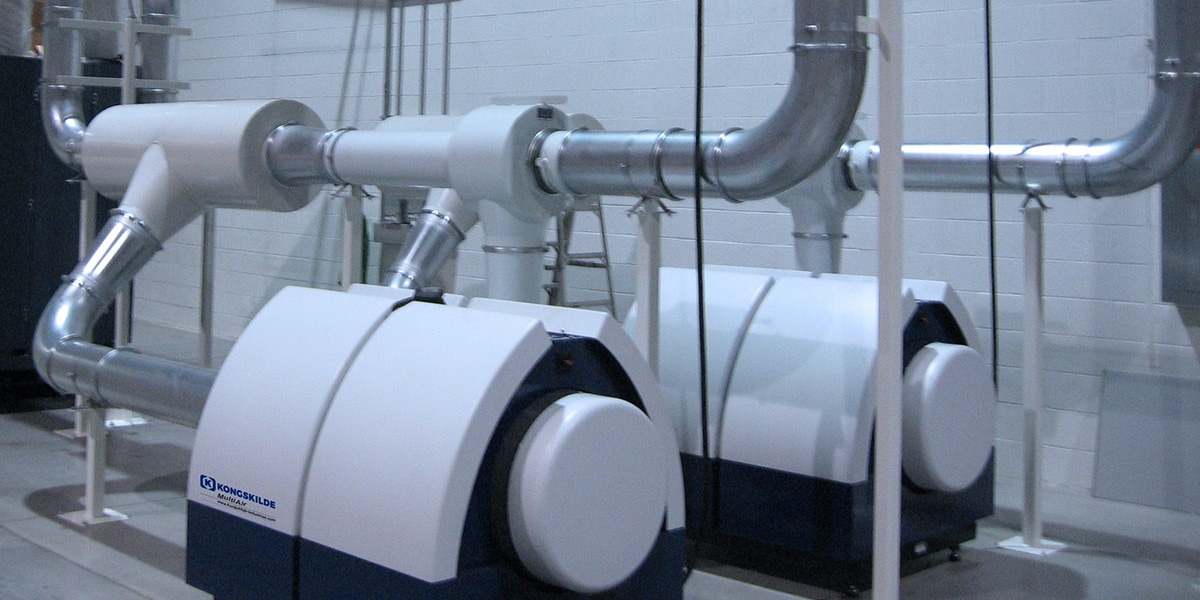

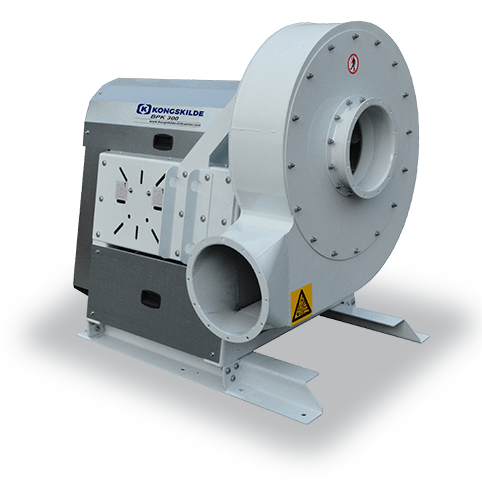

In industries where continuous, high-speed output is the norm, managing off-cuts efficiently is critical. Kongskilde’s pneumatic trim extraction systems offer a reliable and hygienic way to remove shredded materials and cut waste from production lines—helping maintain clean, organized, and uninterrupted operations.

We offer two primary solutions depending on your process:

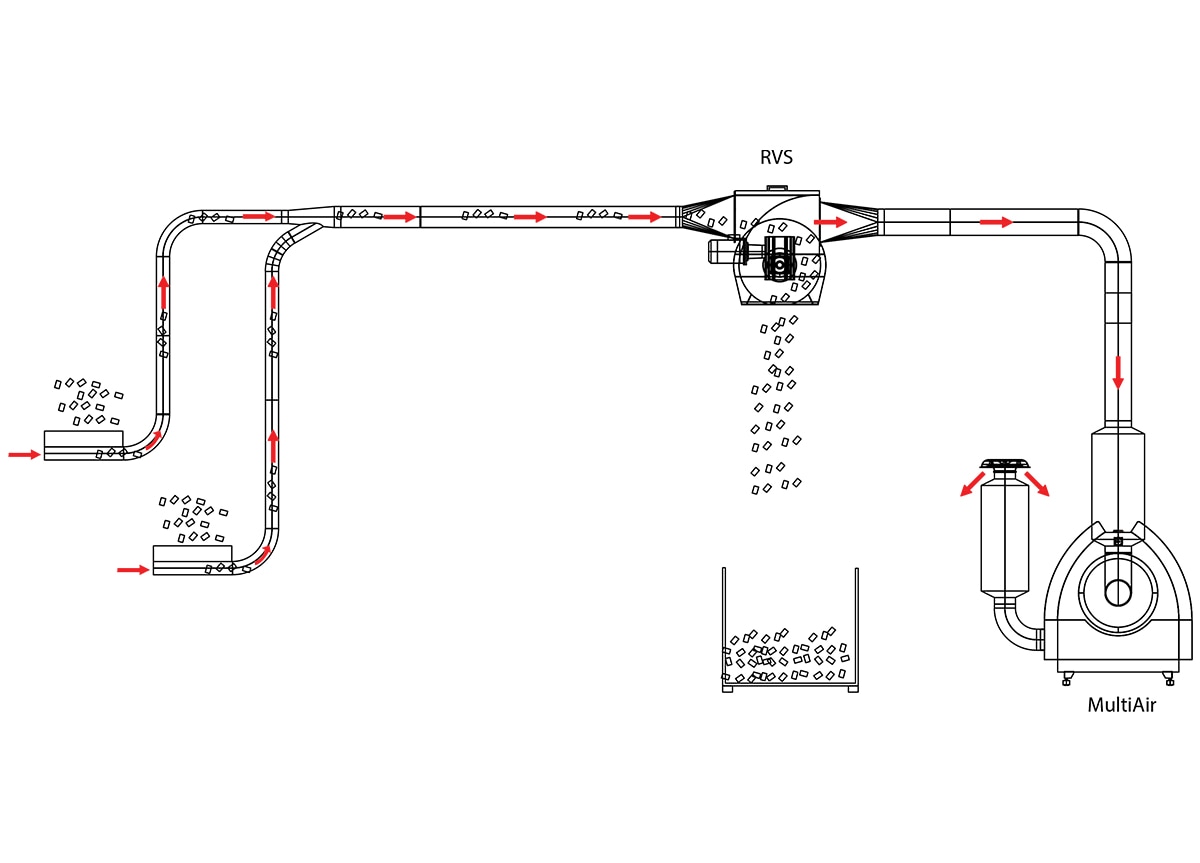

- Kongskilde ITF Venturi and KIV System: This system uses a continuous pipe run with vacuum on the intake side and pressure on the discharge side to transport off-cuts to one or more destination points.

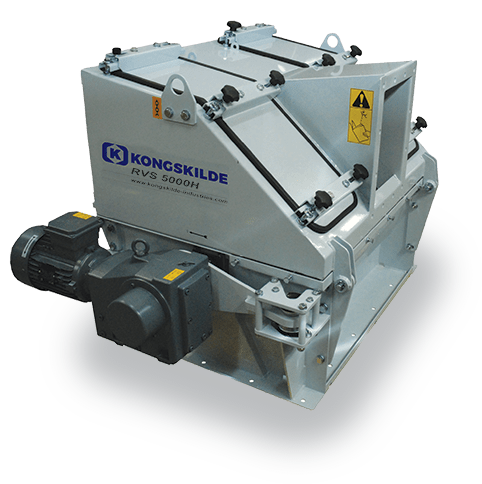

- Rotary Valve Separator (RVS): Using the blower’s vacuum side, this system pulls off-cuts into a separator and can evacuate trim over long distances from multiple machines to a central discharge location.

Whether you’re working with paper, cardboard, plastic film, or foil, Kongskilde’s trim extraction systems are modular, scalable, and built for dependable performance.

Video of Pneumatic Conveying of Off-Cuts

See how automated conveying of cardboard off-cuts helps streamline production and reduce manual handling.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

Case Study

Efficient Removal of Plastic Production Waste at Yogurt Producer – France

A yogurt producer in France wanted to eliminate plastic waste from production lines and reduce manual labour requirements, and separate materials.