Plastics Industries

Pneumatic Solutions for the Plastic Industry

Take your plastic production to the next level with a Kongskilde Industries’ conveying solution designed for the plastic industry. Remove trim, convey material and waste, improve production efficiency, and keep your work environment clean using a pneumatic system.

Blow Moulding

Generate a faster ROI in your blow moulding production by reducing material cost and reducing downtime due to plugged vacuum loader fillers. Kongskilde de-dusting and separation solutions can effectively remove fluff, dust, and debris from the regrind based on material density. This produces higher quality parts and produces less scrap while producing cleaner regrind to give your business a competitive edge and limits the amount of dust in the production environment.

Related Applications

EPS Packaging

Reduce material costs and increase the ROI in your EPS/EPP packaging production with a Kongskilde pneumatic conveying solution. Conveying with an Inline Venturi system maintains the density and integrity of the expanded beads and, in turn, reduces the material cost of the product. Whatever your EPS need, Kongskilde has a conveying to silo storage system for your business.

Related Applications

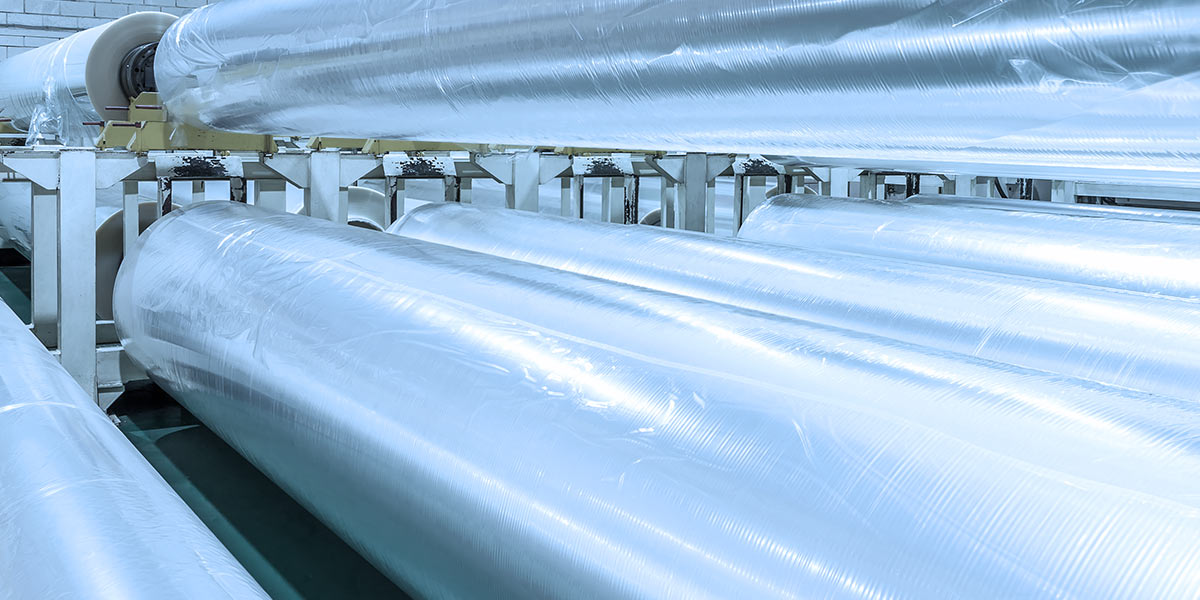

Film Production & Plastic Roll Converting

Improve the efficiency of your plastic film production by quickly removing the continuous trim produced by the re-winding process. Kongskilde pneumatic conveying solutions carry the trim away from the production area through a pipe system. The trim waste is then ready to be disposed of or reused continuously in production. Different types of trim material can be conveyed to dedicated destinations to keep different materials separated.

Related Applications

Flexible Packaging

Streamline and improve your flexible packaging production by quickly removing trims, off-cuts, punch-outs or rejects from the production area. A Kongskilde pneumatic conveying solution removes flexible packaging production waste through a pipe system that can be configured to send the waste outside of the production. Frees up valuable space in the production and keep your working environment clean.

Related Applications

Injection Moulding

Automate the movement of polymer around your injection moulding production facility with a Kongskilde pneumatic conveying solution. Convey sprues to a reclamation area or gently convey the finished parts to storage or packing areas. Ensure energy-efficient material handling by tailoring the solution to your specific needs and exact requirements.

Related Applications

Rail Car

Quickly convey material from a rail car to storage efficiently and without risk of contamination. A Kongskilde high-performance conveying system is flexible and delivers material safely from the rail car with a significantly reduced risk of granulates melting during transport compared to typical PD pump conveying systems. Optimize conveying to and from rail cars while ensuring safe, contamination-free transport of the material.

Related Applications

Recycling

Streamline the recycling process and work environment in your recycling facility. Easily convey granular materials, flakes, and other ground material directly from the grinder or silo. Optimize the conveying of pellets or recycled items like plastic bags and empty plastic bottles, and improve the quality of your recycled material by separating dense and light materials.

Related Applications

Thermoforming Production

Always have enough material ready for your screw extruders to produce the plastic web for the thermoforming process. A Kongskilde pneumatic conveying solution can quickly convey plastic flakes from the grinder to your big-bag station, recycling area or waste depot, saving manual labour and creating more space around your thermoforming line. An aspirator system for de-dusting the flakes improves the value for reuse.

Related Applications

Related processes: separation and dedusting

In the process of cleaning or recycling of plastics, aspirators facilitate the removal of small sized particles and dust from the granulate or flakes.

Aspirator solutions prove an efficient means of dedusting processed materials or granulated plastic. Usable pellets pass through an outlet of the aspirator, after dust is removed and evacuated. This is primarily a method of quality control, but has many different applications.

Industry applications of plastic conveying systems

Plastic, as a lightweight, durable, cheap, and easily modified material, is used in our everyday lives; you are bound to see or use at least one plastic product each day. Some of the largest sectors in terms of plastic usage include construction, packaging, and the automotive industry. In the plastic production process, a multitude of chemicals are used as solvents, initiators, and catalysts. The plastic market is worth billions and continues to grow to this day because the material is always in demand.

Pneumatic conveying increases the efficiency of production and recycling processes, as they simplify and facilitate the rapid transport of relevant materials. The systems must be energy efficient, reliable, adaptable, cost-effective, and operationally safe. Environmental factors, such as energy consumption, also need to be considered prior to installation.

Automated Plastic Conveying

A plastic conveying system is an automated system that moves said material from point A to point B – with point B generally being a single or multiple discharge point(s). Kongskilde Industries recognises the need for a multitude of applications, and thus related solutions, when it comes to the handling of plastics.

Plastic conveyors are used in a variety of industries, from EPS packaging to thermoforming production. Logically, the range of available conveying solutions must be able to accommodate the range of industries using, manufacturing, or recycling plastics.

Vacuum conveyor systems have many advantages, such as dust control, flexibility, and high capacity. In these systems, materials can be transferred from multiple sources to the processing line using negative or positive pressure in an enclosed space.

In the conveying of plastics, it is important to note material characteristics, such as particle density, shapes, and sizes. Standard components of a plastic conveying system are combined in bespoke customer solutions – contingent on the intended purpose. We can design and engineer a custom pneumatic conveying system based on the customer’s unique system requirements.