All-in-one Units

CUB – Compact Unit

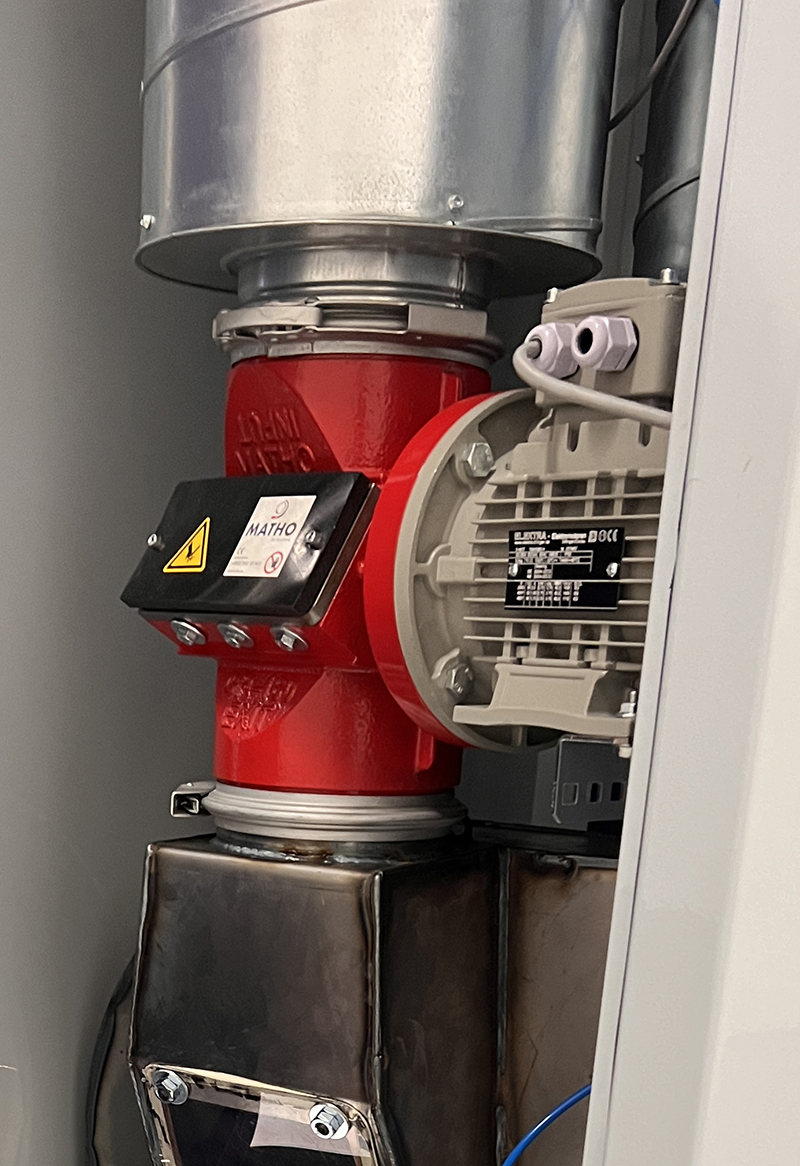

A compact machine-side waste collection unit for process waste

The Kongskilde CUB-1600 is a compact and efficient waste disposal unit designed to streamline production floor waste management across the label, printing, film, extrusion, and packaging industries. It is available with an integrated 900 liter bag, endless bag system, or compactor solution to suit your operational needs.

Built to handle various process waste types, including labels, non-adhesive and self-adhesive edge trims, die-cut pieces, and matrix waste, the CUB-1600 ensures smooth and continuous waste collection. This compact unit can be easily moved between production lines, making it ideal for manufacturers seeking a flexible and efficient waste solution.

Key Features of the CUB Compact Waste Disposal Unit

The CUB compact waste disposal unit offers advanced features designed to support efficient, flexible waste handling in industrial environments:

- Robust Design with Portability: Built to withstand continuous operation, the CUB is compact and highly mobile, moving easily between machines and fitting through standard factory doors.

- Anti-Static and Non-Stick Options: Available in 2 kW and 4 kW models, with versions for basic, antistatic, or non-stick applications, adapting seamlessly to different waste types, including static and sticky materials.

- Integrated Cutting Module: Effectively reduces waste volume to support more efficient handling and disposal.

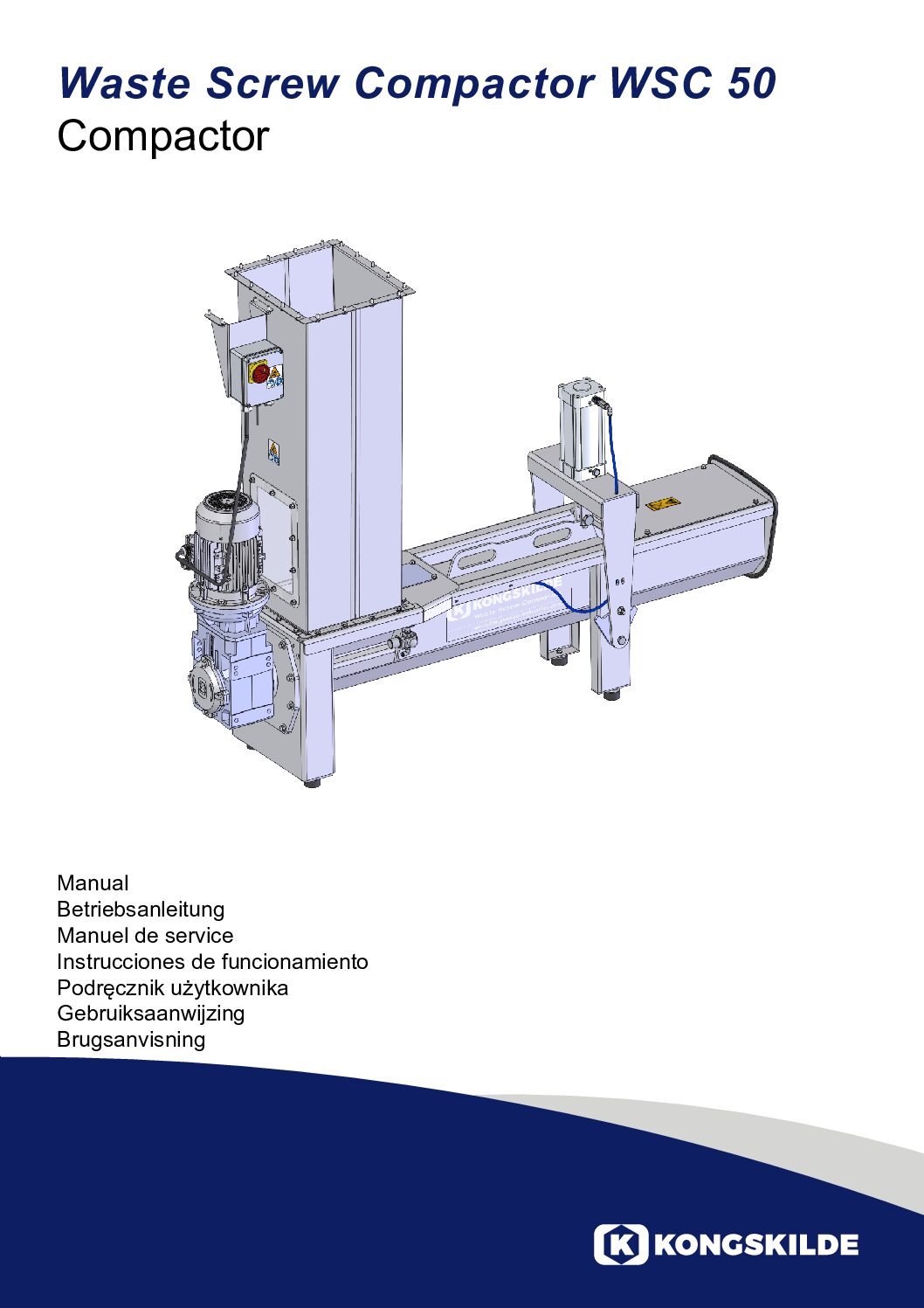

- Flexible Collection Options: Available with an integrated big bag, endless bag system, or compactor solution for direct disposal into a bin to match your operational requirements.

- Quiet Operation: Equipped with large silencers, the CUB operates quietly within production environments, reducing noise disturbances.

- Simple User Controls: The straightforward interface includes push buttons and a speed dial for easy operation.

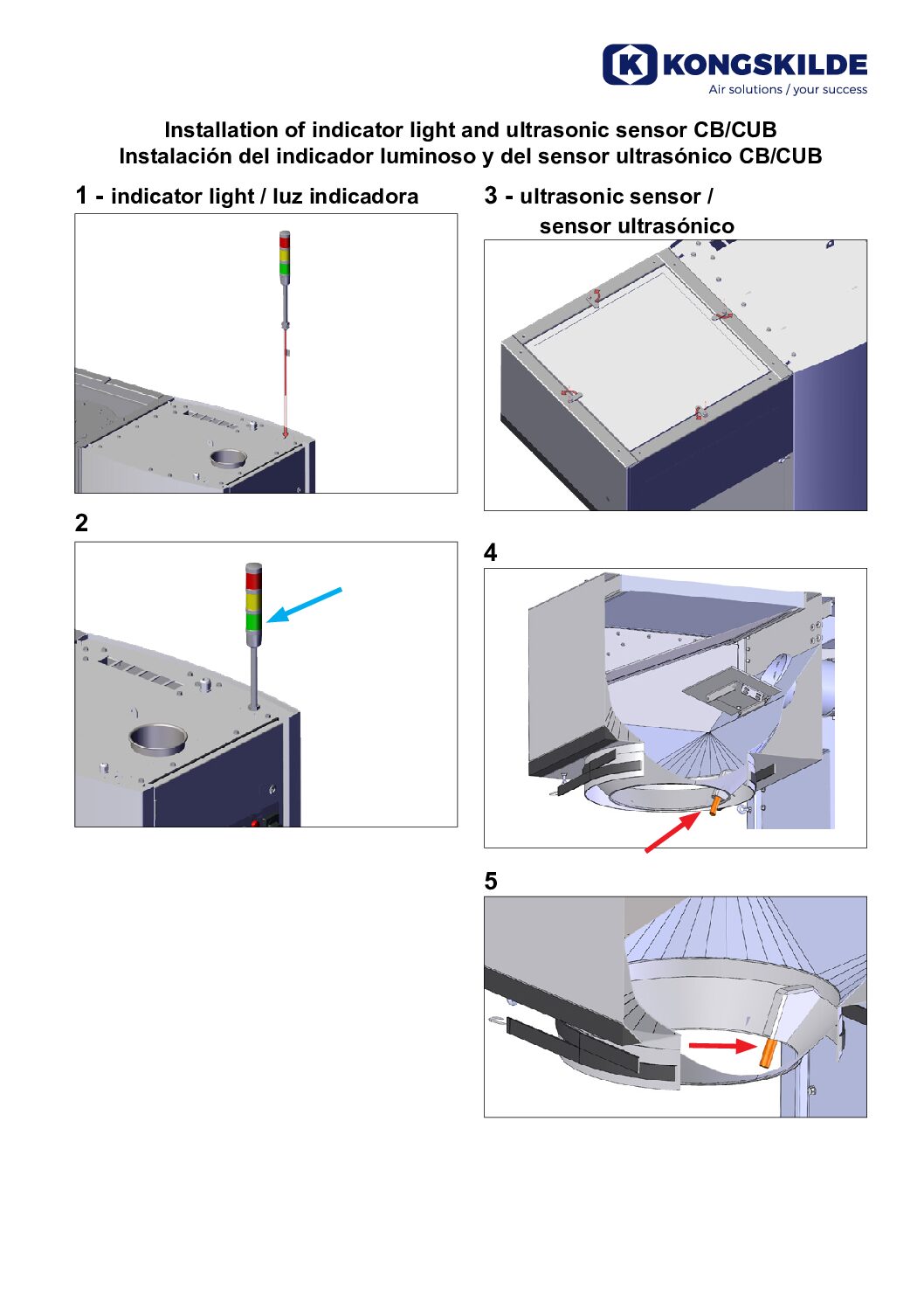

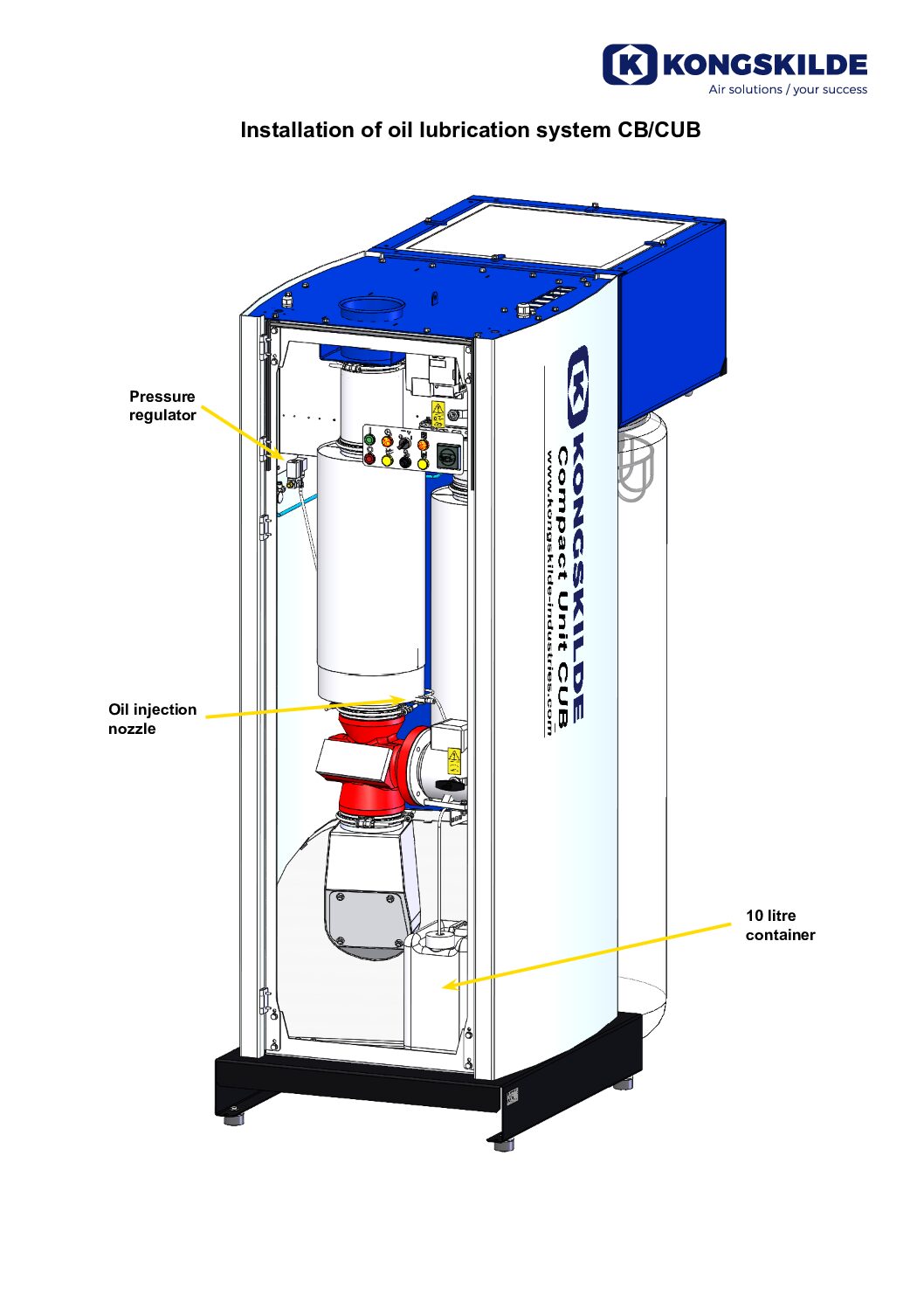

- Optional Accessories: Available accessories include an oil mist system, antistatic kit, HEPA filtration, level sensor with light tower kit for monitoring, endless bag kit for extended operation, and a waste compactor for continuous operation.

Benefits of the CUB Compact Waste Disposal Unit

The Kongskilde CUB-1600 offers significant advantages for efficient waste management in production environments:

- Cost-Effective: Reduces waste handling costs with a built-in cutting module that lowers waste volume. Compaction maximizes bin and transport capacity, reducing the number of waste pickups depending on site conditions.

- Extended Operation with 900-Liter Bag or Endless Bag: Large bag capacity enables longer operation times between bag changes, ideal for extended production.

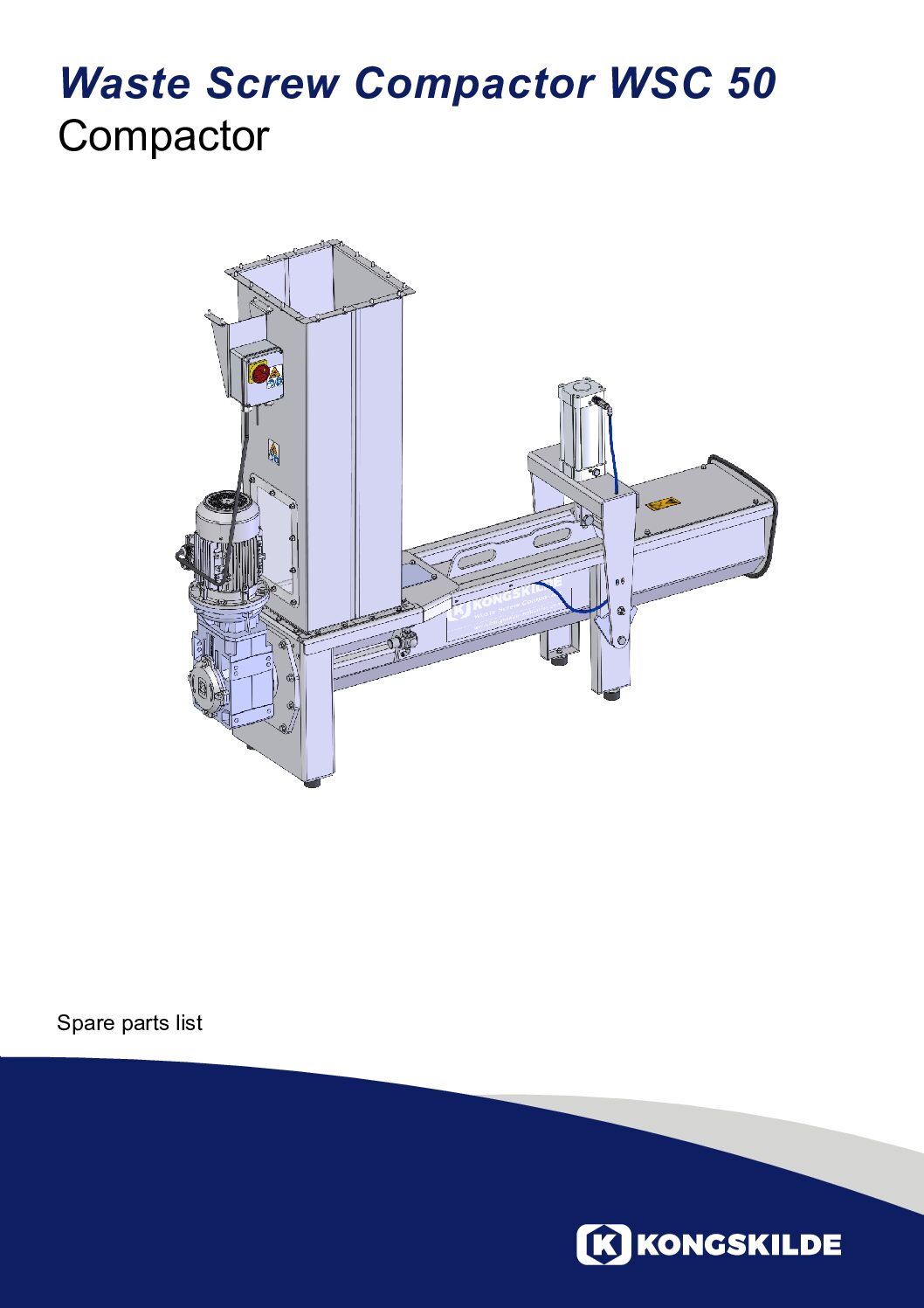

- Continuous Operation with the Waste Screw Compactor: Cut materials are compressed and discharged automatically, removing the need for bag changes and keeping production running without interruption.

- Energy Efficient: Equipped with a high-efficiency blower designed for low energy consumption, helping reduce operating costs.

- Low Maintenance Requirements: Designed with durable materials and efficient waste handling, lowering maintenance costs and improving uptime.

- Improved Safety: Less dust and fewer manual handling tasks create safer working conditions, supported by simple, user-friendly controls.

- Space-Saving Design: Compact footprint (800mm wide and 2150mm high) makes the unit easy to place in confined production areas, and passes effortlessly through most factory doors.

- Improved Workflow with Mobility: Easily moveable with a forklift or pallet jack, allowing for versatile placement throughout the facility.

Applications of the CUB Compact Waste Disposal Unit

The CUB compact waste disposal unit is highly versatile and suitable for various industries and production processes where efficient waste handling is essential:

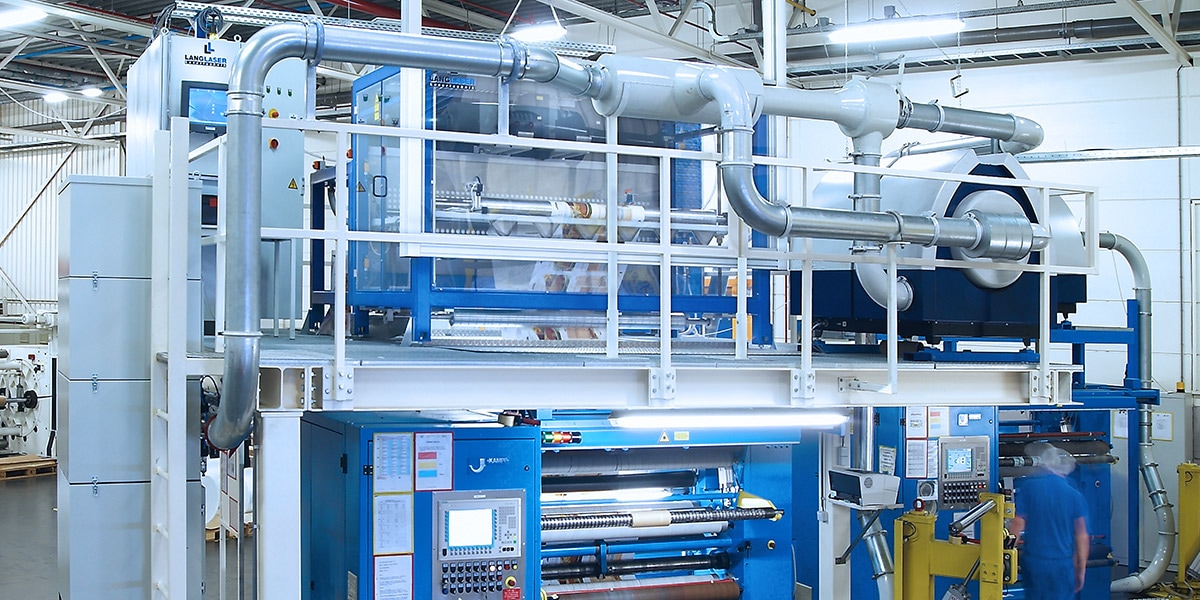

- Label Converting and Printing: Efficiently collects and disposes of adhesive waste, die-cut scraps, and matrix waste for continuous operation.

- Plastic Film Extrusion and Coating: Manages sticky and non-adhesive waste materials, ensuring smooth and uninterrupted production.

- Packaging and Slitting: Ideal for collecting edge trims and die-cut pieces from packaging lines.

- Lamination and Rewinding: Handles non-adhesive and adhesive waste, providing a reliable waste solution for laminated materials.

- General Manufacturing: Flexible waste disposal across diverse manufacturing lines, helping keep production floors clean and organized.

User-Friendly Controls

With push-button controls and a speed dial, the CUB offers intuitive operation without complex programming. Operators can adjust settings quickly to keep production efficient and uninterrupted.

Silent Operation

Large silencers within a steel-enclosed structure to minimize noise, allowing quiet operation close to production lines. This design keeps noise-sensitive areas undisturbed, promoting a comfortable, low-noise work environment.

Flexible Mobility

The compact design of the CUB is highly mobile and can easily be moved with a forklift or pallet jack. It fits through most standard production doorways, enabling quick relocation across production lines for versatile waste collection.

Extended Operation

The CUB unit’s endless bag kit enables extended operation and replacement. For continuous operation, the Waste Screw Compactor allows for unlimited capacity by compacting materials directly into a bin.

Downloads

Download available brochures and data sheets.

Brochures and Data Sheets

Manuals and Spare Parts

Replacement accessories for the CUB are available for purchase, including standard Big Bags, Endless Bags, and HEPA filters. Contact us for more information.

CUB Model Comparison

Compare available Compact Unit – Bag models. Visit the downloads section for more information on specific models.

| CUB-1620 | CUB-1640 | |

|---|---|---|

| Material thickness | 40 – 300 μm | 40 – 300 μm |

| Blower Motor | 2.2 kW | 4.0 kW |

| Cutter Motor | 0.75 kW / 1,500 RPM | 0.75 kW / 1,500 RPM |

| Height x Width x Length | 2,150 x 800 x 1,570 mm | 2,150 x 800 x 1,570 mm |

Compact Unit Videos

Learn more about the Kongskilde Compact Unit and see it in action.

CUB Applications

The CUB is suitable for a wide range of waste handling applications, including label matrix waste, edge trims, die-cut scraps, adhesive waste, plastic film, laminated materials, and general production waste.