The Challenge

Improving Waste Handling Efficiency in Flexible Film Packaging

A factory in Poland, specialising in the manufacturing of high-quality flexible film packaging for the food, pharmaceutical and industrial sectors, needed a solution that would enable the quick and automated removal of film scraps. Their main challenges included:

- Scrap Removal Needed to Be Automated: Manual removal of film scraps from production lines slowed operations and introduced unnecessary labor demands.

- Transport Bottlenecks Disrupted Workflow: Scraps from rewinding and cutting machines required reliable, continuous transport to compactors to reduce downtime and improve efficiency.

- Air Quality and Energy Use Lacked Optimization: The facility needed a system that could filter and recirculate air, reduce energy consumption through adjustable-power blowers, and ensure full compliance with health and safety regulations.

The Facts

- Material: Plastic and aluminium scraps from rewinding and cutting machines.

- Capacity: Up to 400 m/min

- Thickness: 100μ,

- Trim Size: Max 500mm skeleton

- Transport Distance: Up to 95 m horizontally and 12 m vertically

- System Requirements: The system must be able to handle different waste widths including scraps from rewinding machines up to 50 mm and cut-outs from cutting machines up to 500 mm.

The Solution

To address the challenges, the company implemented a custom Kongskilde pneumatic transport system that vacuums film scraps directly from production machines, shreds them and transports them to press containers, streamlining waste management and eliminating dust, minimising downtime.

- The system includes a series of MultiCutters connected to production machines, with BTK blowers providing the pneumatic power to transport material through OK and FK piping. A DS filter handles air purification, while MTD blowers return clean air to the production hall.

- The scraps, shredded using a MultiCutter grinder, are sent to a KU static separator, which separates the waste from the air, ensuring a smooth flow of material regardless of the thickness and width of the waste.

- The air sucked in from production is filtered by the Kongskilde system and returned to the production hall, which eliminates negative pressure in the hall and allows employees to breathe freely.

- The main blower is controlled by a frequency converter that adjusts its speed to reduce energy consumption depending on the number of machines in operation.

The Advantages and Benefits

By implementing Kongskilde’s automated waste extraction and air filtration system, the factory resolved its core operational challenges, achieving measurable improvements in efficiency, sustainability, and working conditions. The following benefits demonstrate the impact of the solution:

- Continuous, Efficient Waste Removal: The pneumatic system enables uninterrupted scrap extraction directly from production lines, minimizing downtime and maintaining consistent workflow.

- Cleaner Air and a Healthier Work Environment: Dust and particles are separated from the airflow, which is filtered and recirculated into the hall—improving air quality and ensuring compliance with workplace safety standards.

- Reduced Energy Consumption: Blower speed is automatically adjusted based on machine load, optimizing power use and significantly lowering operational energy costs.

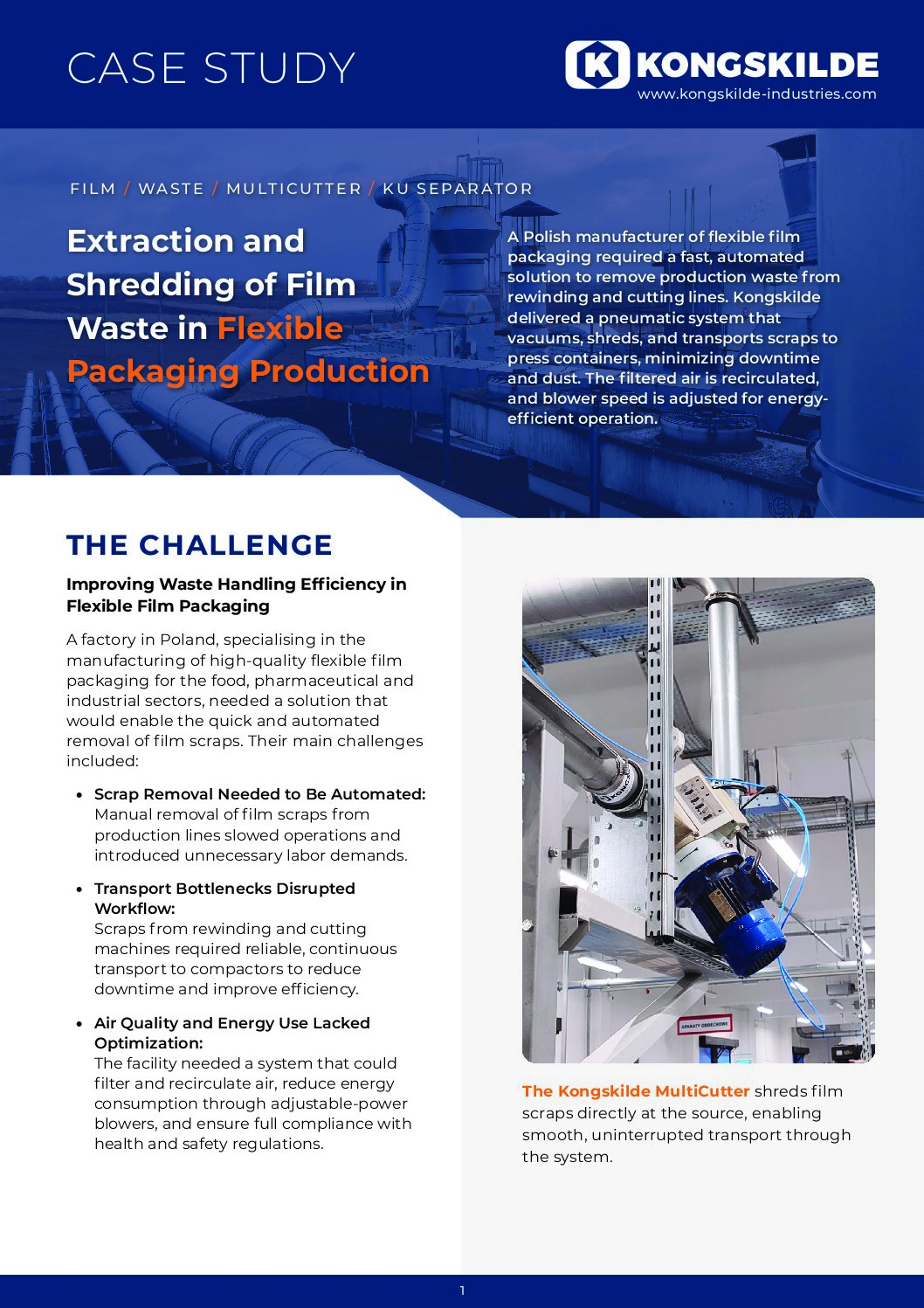

The Kongskilde MultiCutter shreds film scraps directly at the source, enabling smooth, uninterrupted transport through the system.

The KU Static Separator directs bulk materials into a stationary compactor, baler, or container, while the conveying air is efficiently expelled, enabling clean, efficient waste collection.

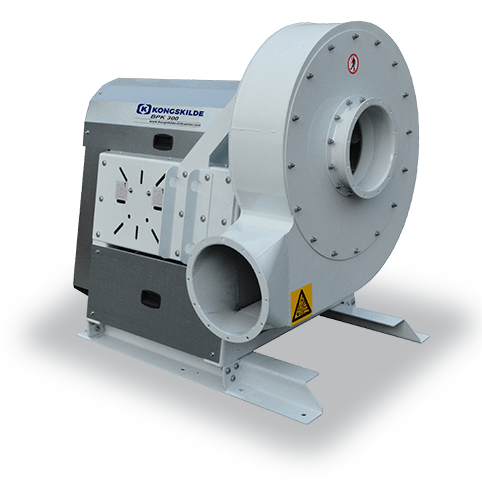

The BTK Blower is designed for continuous transport of materials, like shredded film scraps, through a closed loop conveying system.