Suction Blowing Systems

Polyvac (North America Only)

Integrated high capacity vacuum conveying system

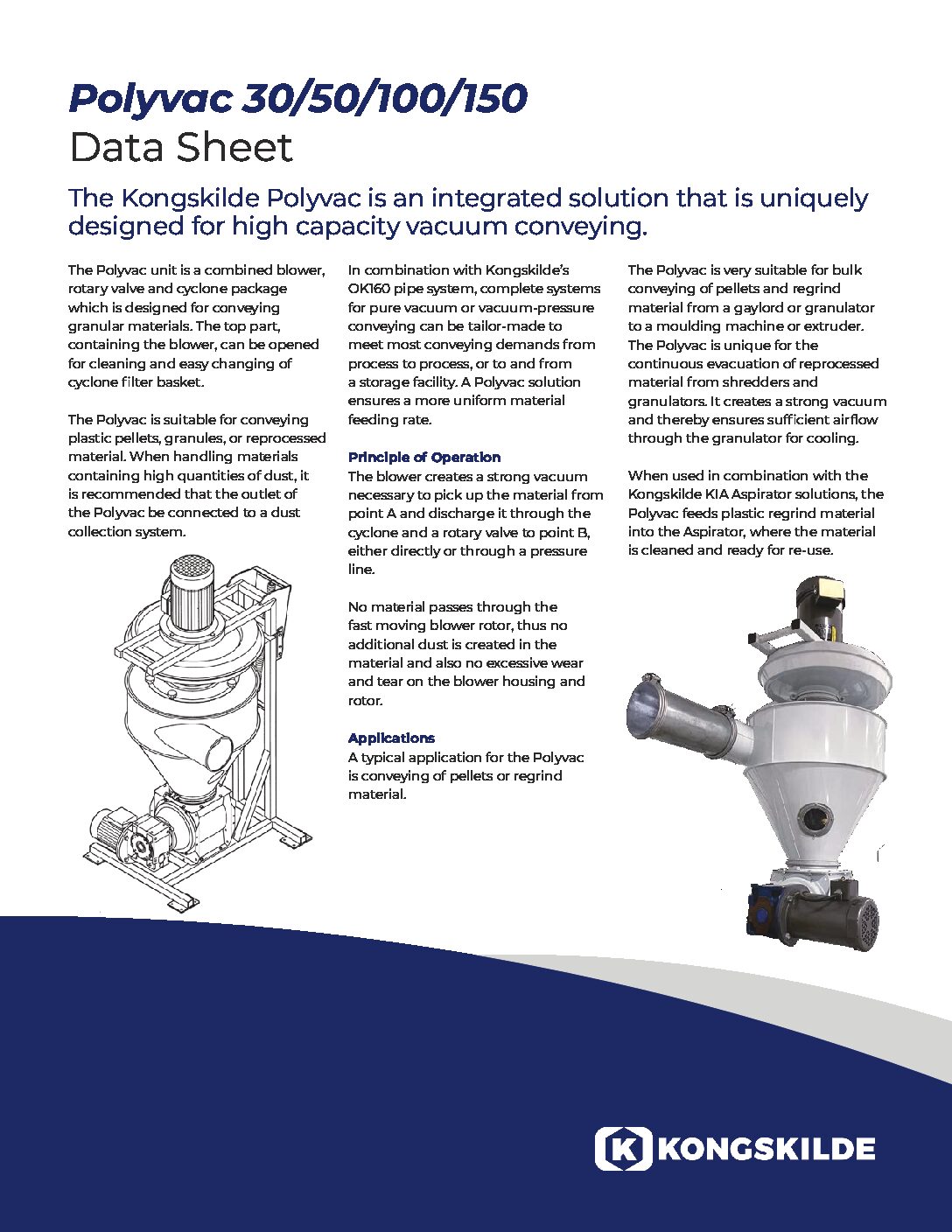

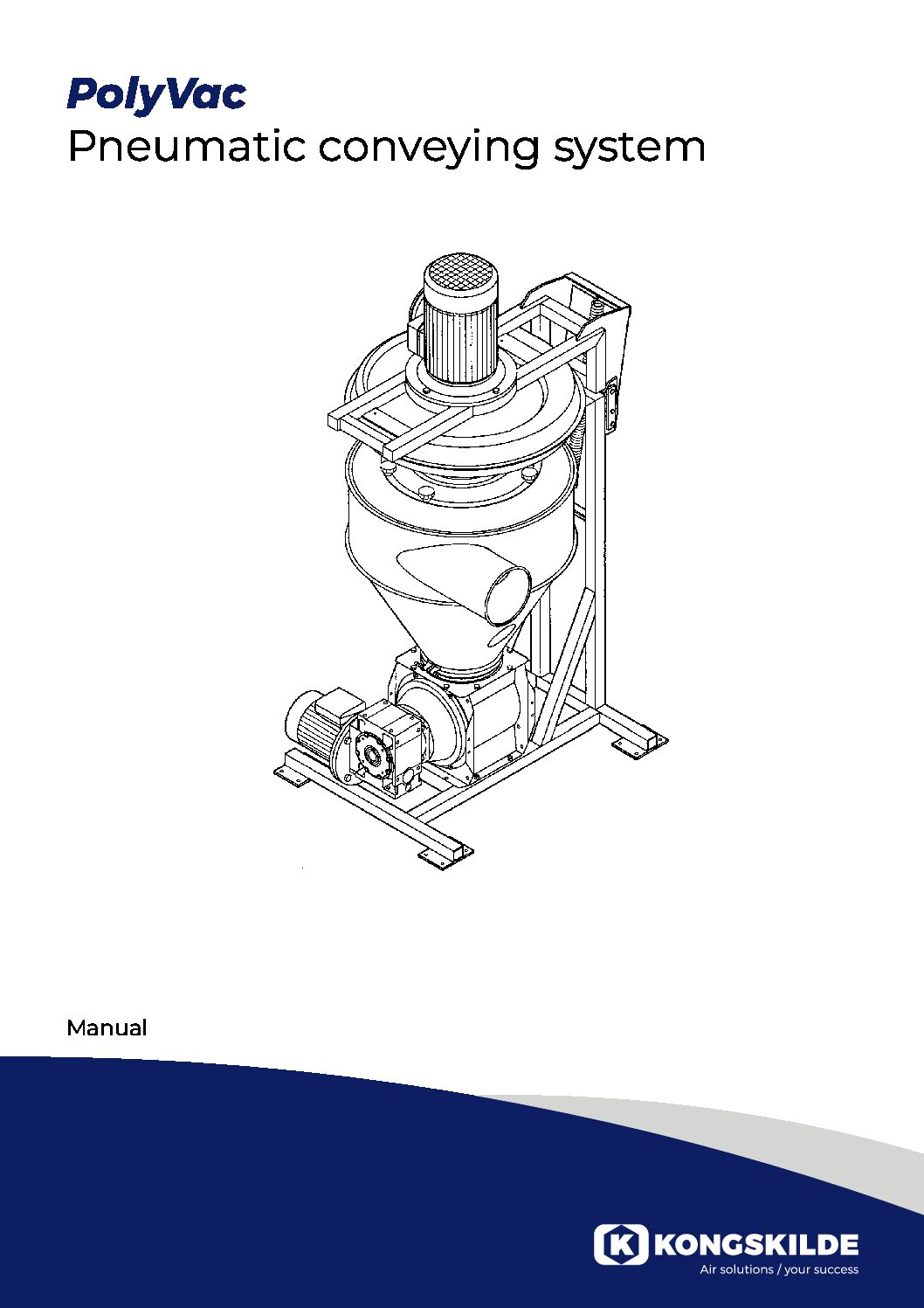

Kongskilde’s Polyvac systems offer an integrated solution uniquely designed for high-capacity vacuum conveying of granular materials. The Polyvac unit, available exclusively in North America, combines a blower, rotary valve, and cyclone in one compact package, optimized for efficient handling of plastic pellets, granules, and reprocessed materials. Its innovative design allows for easy cleaning and quick changes of the cyclone filter basket, making it an ideal choice for plastic processing industries.

Available in North America only.

Streamlining Material Conveyance

The Polyvac system operates on a powerful vacuum created by its built-in blower, effectively picking up materials from one location and transporting them to another through its integrated cyclone and rotary valve setup.

In combination with Kongskilde’s OK160 pipe system, the Polyvac can be configured for either pure vacuum or vacuum-pressure conveying, allowing for custom solutions tailored to meet specific industrial needs.

This flexibility makes it possible to design complete conveying systems that can handle a variety of demands, whether moving materials from process to process or from and to storage facilities. Materials are moved safely and efficiently without passing through the fast-moving blower rotor, minimizing wear and tear and preventing any additional dust generation during transport.

Benefits of Kongskilde Polyvac Systems

- High Efficiency: Designed for high-capacity conveying, perfect for large-scale industrial applications.

- Low Maintenance: Easy access for cleaning and maintenance with a design that reduces wear on components.

- Dust Reduction: Works seamlessly with dust collection systems to maintain clean operational environments.

- Versatile Applications: Ideal for transporting pellets and regrind material from storage to processing machines or between production stages.

Applications

The Polyvac system is highly adaptable, making it essential in various industrial scenarios, particularly in plastics processing:

- Bulk Material Transfer: Ideal for transferring pellets and regrind material from storage containers or granulators to molding machines or extruders.

- Continuous Material Evacuation: Effectively evacuates reprocessed material from shredders and granulators, maintaining sufficient airflow for cooling.

- Integrated Cleaning: When used with the Kongskilde KIA Aspirator, it cleans plastic regrind material, preparing it for reuse and supporting sustainable manufacturing practices.

Downloads

Download manuals, data sheets, and spare parts lists for the Polyvac.

Compare Models

Compare available Polyvac models.

| Polyvac 30 | Polyvac 50 | Polyvac 100 | Polyvac 150 | |

|---|---|---|---|---|

| Blower, hp | 3 | 5 | 10 | 15 |

| Rotary valve, hp | 0.75 | 0.75 | 0.75 | 0.75 |

| Weight, lbs | 100 | 168 | 240 | 345 |

| Height with hinge for blower, in | n/a | n/a | 14’2″ | 14’5″ |

| CFM | 1200 | 1200 | 2100 | 2500 |

| Pipe diameter, mm | 160 | 160 | 200 | 200 |

Polyvac Applications

The Polyvac system is extremely versatile, ideal for industries that process plastic pellets, granules, and reprocessed materials. It excels in applications where bulk material needs to be moved efficiently, such as from storage to molding machines or extruders, and is particularly effective in facilities that handle high volumes of regrind material, ensuring continuous operation without compromising on performance.